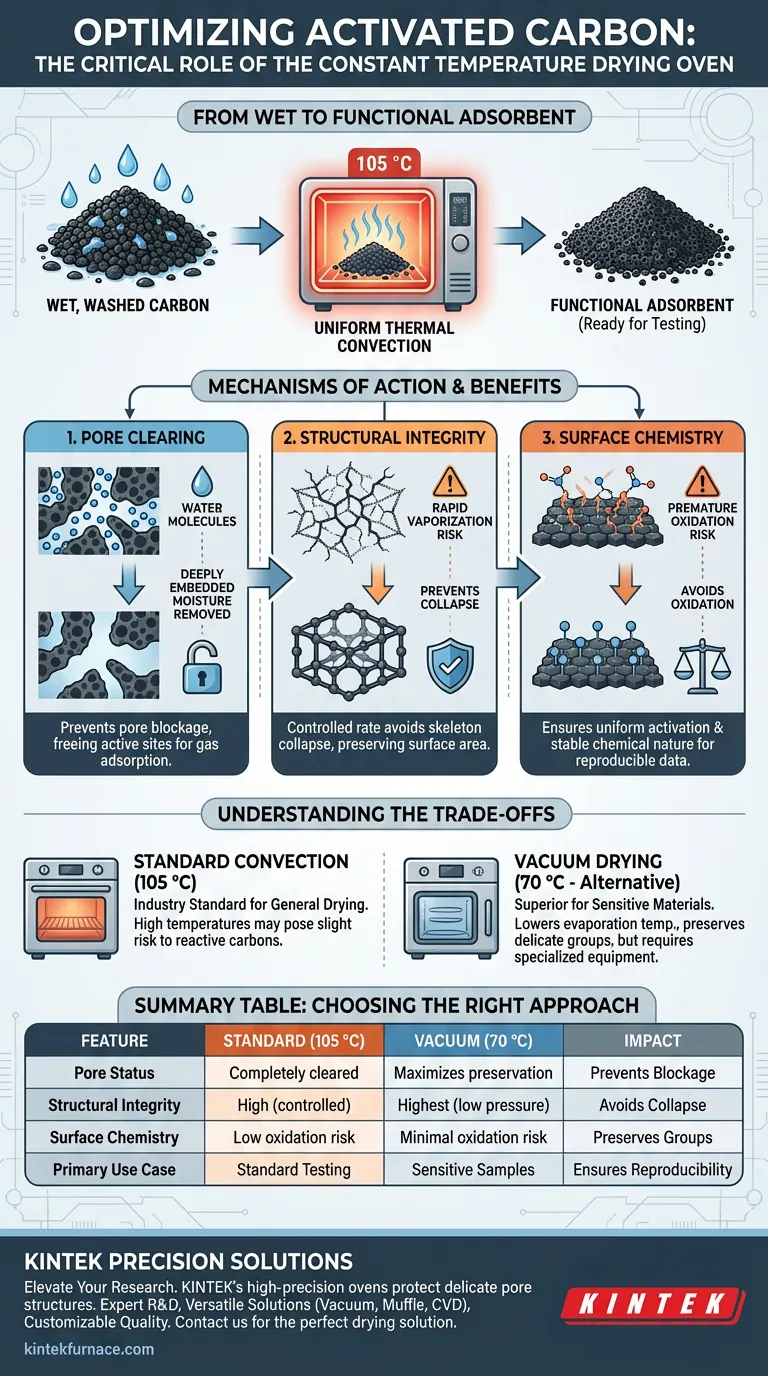

The use of a constant temperature drying oven is the definitive step for transitioning activated carbon from a wet, washed state to a functional adsorbent. It utilizes continuous, uniform thermal convection—typically set at 105 °C—to completely eliminate residual moisture from the carbon’s internal pore structure without compromising its surface chemistry.

The core purpose of this process is to ensure the material reaches a "completely dry and activated state" without sustaining damage. If moisture remains, it physically blocks pores; if the temperature fluctuates or gets too high, it chemically degrades the surface. The oven balances these risks to prepare the carbon for accurate CO2 adsorption testing.

Mechanisms of Pore Clearing and Activation

Removing Deeply Embedded Moisture

Washing activated carbon is essential for removing ash and chemical residues, but it leaves the pore network saturated with water. The constant temperature oven provides a controlled dehumidification environment.

This process removes not just surface water, but moisture trapped deep within the micropores. Without this thorough drying, water molecules occupy the active sites intended for gas adsorption, rendering the material ineffective during testing.

Preventing Structural Collapse

While the primary goal is moisture removal, the rate of removal matters. A constant, controlled temperature prevents the rapid, violent vaporization of water that can occur if wet carbon is immediately subjected to extreme heat (such as in a furnace).

By drying the material steadily at 105 °C, you ensure the physical integrity of the porous structure is maintained, avoiding the collapse of the carbon skeleton that effectively destroys the material's surface area.

Preserving Surface Chemistry

Avoiding Premature Oxidation

Activated carbon relies on specific surface functional groups to bind with contaminants. Uncontrolled heating in an oxygen-rich environment can cause these groups to oxidize prematurely, altering the carbon's chemical nature before it is ever used.

The constant temperature oven mitigates this by maintaining a thermal environment that is hot enough to drive off water but stable enough to prevent unwanted oxidation reactions on the carbon surface.

Ensuring Uniform Activation

Temperature fluctuations during drying can lead to "hot spots" and "cold spots." This results in a batch of carbon where some particles are over-dried (oxidized) and others remain damp.

A precision constant temperature oven ensures uniform thermal convection. This guarantees that every gram of the final product has equivalent adsorption characteristics, which is vital for the reproducibility of experimental data and concentration calculations.

Understanding the Trade-offs

Standard Convection vs. Vacuum Drying

While a standard constant temperature oven (at 105 °C) is the industry standard for general drying after washing, it has limitations regarding highly sensitive materials.

The Limitation: Standard atmospheric drying requires higher temperatures to evaporate water, which poses a slight risk of thermal oxidation or pore shrinkage in highly reactive carbons.

The Alternative: As noted in advanced applications, a vacuum drying oven can be used as an alternative. By lowering the ambient pressure, water evaporates at significantly lower temperatures (e.g., 70 °C). This method is superior for preserving delicate organic functional groups and preventing the shrinkage of active pores, though it requires more specialized equipment.

Making the Right Choice for Your Goal

Depending on the sensitivity of your activated carbon and the precision required for your application, your approach to drying may vary.

- If your primary focus is Standard Adsorption Testing: Adhere to the standard protocol of a constant temperature oven at 105 °C to ensure complete moisture removal and accurate weight measurements.

- If your primary focus is Surface Chemistry Preservation: Consider using a vacuum drying oven at lower temperatures (approx. 70 °C) to minimize the risk of thermal oxidation or pore blockage in sensitive samples.

- If your primary focus is Structural Integrity: Prioritize long-duration, stable drying to prevent rapid vaporization that could damage the carbon skeleton during subsequent high-heat applications.

The constant temperature oven is not merely a drying tool; it is a stabilization device that locks in the physical and chemical properties created during the activation process.

Summary Table:

| Feature | Standard Drying (105 °C) | Vacuum Drying (70 °C) | Impact on Activated Carbon |

|---|---|---|---|

| Pore Status | Completely cleared of water | Maximizes pore preservation | Prevents blockage of active sites |

| Structural Integrity | High (controlled rate) | Highest (low pressure) | Avoids collapse of the carbon skeleton |

| Surface Chemistry | Low risk of oxidation | Minimal risk of oxidation | Preserves functional binding groups |

| Primary Use Case | Standard Adsorption Testing | Sensitive Organic Samples | Ensures data reproducibility |

Optimize Your Carbon Activation with KINTEK Precision

Don't let moisture compromise your research results. KINTEK’s high-precision constant temperature and vacuum drying ovens are designed to protect the delicate pore structures of your activated carbon, ensuring maximum adsorption capacity and structural integrity.

Why choose KINTEK?

- Expert R&D: Systems engineered for uniform thermal convection and stable environments.

- Versatile Solutions: From standard drying to specialized Vacuum, Muffle, and CVD systems.

- Customizable Quality: Tailored to meet your specific lab high-temperature and drying needs.

Ready to enhance your lab's efficiency and experimental accuracy? Contact our technical experts today to find the perfect drying solution for your materials.

Visual Guide

References

- Dang Duc Viet, Toshiki Tsubota. Autohydrolysis treatment of bamboo and potassium oxalate (K2C2O4) activation of bamboo product for CO2 capture utilization. DOI: 10.1007/s11705-024-2402-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the advantages of using electron bombardment heating systems for Niobium? Achieve Industrial Fidelity

- Why is a pre-melting process required in phase equilibrium studies? Reset Your Sample for Precise Results

- What are the main types of sintering furnaces? Find the Perfect Match for Your Materials

- Why is precise sample loading critical in CO2 capture experiments? Avoid Bed Effects and Ensure Data Integrity

- What are the key requirements for steel materials in high-speed rail, nuclear power, and aerospace industries? Unlock High-Performance Steel Solutions

- How does temperature control affect nanoporous copper dealloying? Master Pore Uniformity and Size

- Why are aluminum alloy castings subjected to high-temperature testing in an industrial blister oven? Reveal Defects

- Why is an ultra-thin ruthenium buffer layer used for sapphire and Ru50Mo50? Optimize Your Thin Film Quality