Tube Furnace

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

Item Number : KT-TF17

Price varies based on specs and customizations

- Max. temperature

- 1700℃

- Furnace tube material

- High grade Al2O3 alumina

- Heating zone length

- 300 / 450 / 600 / 800 mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

KINTEK: Your Partner in Advanced High-Temperature Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD/MPCVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Need a specialized furnace configuration? Contact our experts to discuss your custom requirements and discover how we can support your research and production goals.

Tube Furnace with Alumina Tube: Precision and Reliability for High-Temperature Processes

KINTEK's Tube Furnace with Alumina Tube is expertly designed for laboratory and industrial high-temperature applications reaching up to 1700°C. It is a cornerstone for processes such as material synthesis, chemical vapor deposition (CVD), vacuum sintering, and specialized heat treatments. At its heart, a high-purity alumina ceramic tube provides exceptional thermal insulation and robust resistance to high temperatures, as well as acidic and alkaline environments. This ensures precise temperature control, a clean and inert processing atmosphere, minimal contamination, and extended operational life. Benefit from its compact design and reliable performance for your critical high-temperature experiments and production.

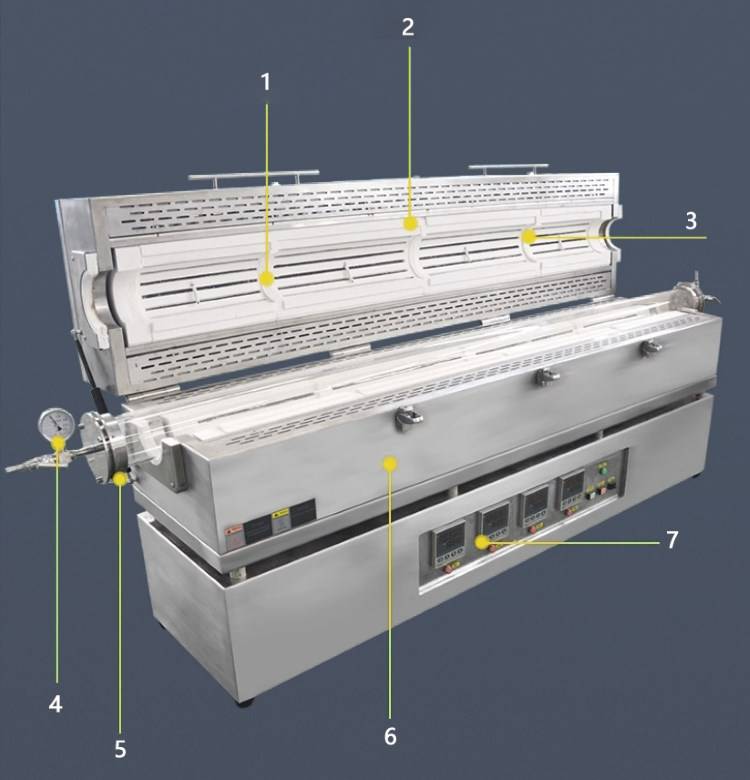

Detailed Views & Components

Key Features & Advantages of KINTEK's Tube Furnace

- Compact & Versatile Design: Optimized for a small footprint without compromising on functionality, making it suitable for diverse laboratory environments and a wide range of applications, including high-temperature pyrolysis and composition analysis.

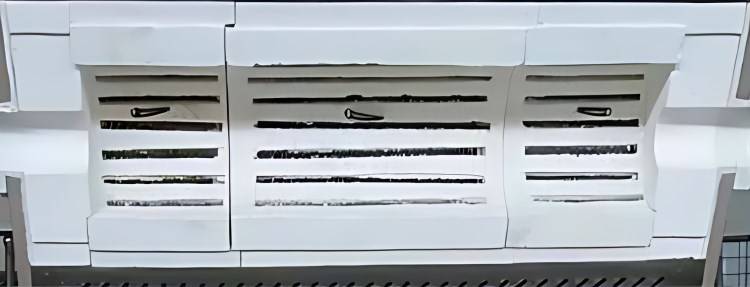

- Enhanced Safety & Efficiency: Features a double furnace shell design with forced air cooling, ensuring a low surface temperature for operator safety and improved energy efficiency.

- Precise Temperature Management: Equipped with PID programmable temperature control for exceptional accuracy and stable heating. Supports remote monitoring and centralized control for streamlined operations. The KT-TF17 Pro model features a user-friendly 7-inch TFT touch screen for intuitive program setting, historical data analysis, and storage for multiple program recipes.

- Durable High-Purity Alumina Tube: Utilizes a high-purity alumina tube (Al2O3) offering excellent resistance to acids and alkalis, withstands high working temperatures (up to 1700°C), ensures minimal sample contamination, and provides a long service life for a better return on investment. Note: Alumina tubes are subject to thermal shock; smaller diameter tubes generally perform better in this regard.

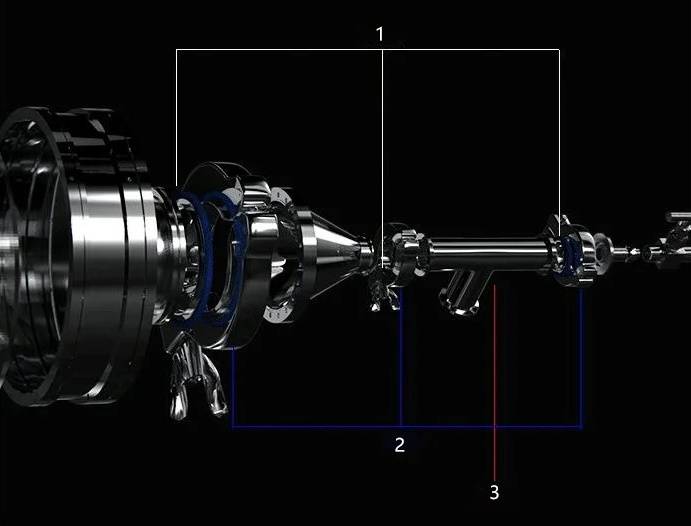

- Robust Vacuum Capability: Includes stainless steel vacuum flanges with various adapting ports, ensuring excellent sealing for high vacuum pressure applications (rated up to 0.001Pa) and compatibility with different vacuum pump setups.

- Flexible Operation: KINTEK manufactures tube furnaces for operating temperatures up to 2000°C (model specific). We offer vertical and horizontal tube models, bottom-loading vertical tubes, and combination units for maximum versatility.

- Customizable Options: Water-cooled end caps and gas mixing systems are available to tailor the furnace to specific experimental needs, reflecting KINTEK's commitment to providing customized solutions.

Advanced Safety Protections

- Kindle Tech tube furnace owns over-current protection and over-temperature alarming function; the furnace will turn off the power automatically once over-current is detected.

- The furnace has a built-in thermocouple detecting function; the furnace will stop heating and an alarm will be triggered if the thermocouple is broken or a failure is detected.

- The TF17 Pro (and similar advanced models) supports a power failure restarting function; the furnace will resume the heating program when power is restored after an outage.

Versatile Applications

The Tube Furnace With Alumina Tube is a versatile and essential tool in various high-temperature test and analysis scenarios across multiple industries. Its applications are particularly focused on environments requiring controlled heating zones and high-temperature resistance. Key application areas include:

- Material Science Research: Ideal for experiments involving the synthesis, processing, and characterization of new materials at high temperatures, including ceramics, composites, alloys, and refractory materials.

- Chemical Vapor Deposition (CVD) & Physical Vapor Deposition (PVD): Provides the controlled atmosphere and temperature necessary for thin film deposition processes.

- Sintering and Annealing: Used for densification of powders, stress relief, and microstructure modification of various materials.

- Coal Testing and Analysis: Employed for precise heating and analysis of coal samples to determine their properties (e.g., ash content, volatile matter) and suitability for various industrial uses.

- Metallurgical Powder Testing and Analysis: Essential for the heating and analysis of metallic powders, aiding in the development and quality control of metal alloys and composites.

- Chemical and Glass Industry Testing: Used in the heating and processing of glass and chemical samples for property analysis, crucial for developing new compositions and products.

- Pharmaceutical and Biotechnology Industries: Applicable for sterilization, purification, and processing of materials and equipment in controlled high-temperature environments.

Operating Principle

Tube furnaces utilize a heating element, such as a resistive heating coil (e.g., Cr2Al2Mo2 wire) or silicon carbide, to heat a process tube. This process tube, typically made of a high-purity ceramic material like alumina (Al2O3), is positioned within an insulated furnace chamber to minimize heat loss. The temperature inside the process tube is precisely regulated by a temperature controller (often PID-based), which monitors the tube's temperature via a thermocouple and adjusts the power supplied to the heating element accordingly. This controlled heating environment makes tube furnaces indispensable for a variety of applications, including heat treating, annealing, sintering, and material synthesis under controlled atmospheres or vacuum.

Technical Specifications

| Furnace model | KT-TF17 | KT-TF17 Pro |

| Temperature controller | Digital PID controller | Touch screen PID controller |

| Multi program preset | no | yes |

| Power failure restarting | no | yes |

| Max. temperature | 1700℃ | |

| Constant work temperature | 1650℃ | |

| Furnace tube material | High grade Al2O3 alumina | |

| Furnace tube diameter | 30 / 40 / 60 / 80 / 100 mm | |

| Heating zone length | 300 / 450 / 600 / 800 mm | |

| Heating zone quantity | 1-10 zones | |

| Vacuum sealing solution | SS 304 flange with O ring | |

| Rated vacuum pressure | 0.001Pa/10E-5 torr (corrected from 10E5) | |

| Rated positive pressure | 0.02Mpa/150 torr | |

| Chamber material | Japan Al2O3 alumina fiber | |

| Heating element | Cr2Al2Mo2 wire coil | |

| Heating rate | 0-10℃/min | |

| Temperature sensor | B type Thermal couple | |

| Temperature control accuracy |

±1℃ |

|

| Temperature uniformity |

±5℃ |

|

| Electric power supply | AC110-220V,50/60HZ | |

| Other Al2O3 alumina tube sizes and heating zone lengths can be customized | ||

Standard Package Inclusions

| No. | Description | Quantity |

| 1 | Furnace | 1 |

| 2 | Alumina tube | 1 |

| 3 | Vacuum flange set (pair) | 1 (set of 2) |

| 4 | Tube thermal block (pair) | 1 (set of 2) |

| 5 | Tube thermal block hook | 1 |

| 6 | Heat resistant glove (pair) | 1 |

| 7 | Operation manual | 1 |

Enhance Your Setup: Optional Customizations

KINTEK specializes in tailoring furnace systems to your exact research or production needs. Beyond our standard offerings, consider these optional setups and customizations:

- Gas Atmosphere Control:

- In-tube gas detection and monitoring (e.g., H2, O2, Ar, N2).

- Precise gas feeding and flow rate control using mass flow controllers (MFCs) or float flowmeters.

- Multi-gas mixing systems.

- Vacuum Systems:

- Comprehensive high vacuum pump station setups, including rotary vane pumps, molecular pumps, and diffusion pumps, to achieve desired vacuum levels.

- Temperature Control & Data Logging:

- Advanced touch screen temperature controllers with versatile operator-friendly functions, enhanced data logging, and recipe management.

- Independent furnace temperature monitoring and recording systems for validation and quality control.

- RS 485 communication port for PC remote control and data exporting.

- Physical Modifications:

- Custom tube diameters and lengths.

- Multiple, independently controlled heating zones.

- Specific orientations (vertical, horizontal, tilting).

Don't see what you need? Our R&D and manufacturing capabilities allow for deep customization. Contact us today to discuss your specific requirements and let us build the perfect high-temperature solution for you!

Trusted by Industry Leaders

FAQ

What Is A Tube Furnace And How Does It Work?

What Are The Main Applications Of A Rotary Tube Furnace?

What Are The Common Applications Of A Split Tube Furnace?

What Is A Vertical Tube Furnace?

What Are The Main Applications Of Multi-zone Tube Furnaces?

What Are The Main Applications Of Tube Furnaces?

What Are The Key Features Of A Rotary Tube Furnace?

What Are The Key Features Of A Split Tube Furnace?

What Are The Applications Of A Vertical Tube Furnace?

What Are The Key Features Of Multi-zone Tube Furnaces?

What Are The Advantages Of Using A Tube Furnace?

How Does A Rotary Tube Furnace Work?

How Does A Split Tube Furnace Work?

What Are The Advantages Of A Vertical Tube Furnace?

How Does A Multi-zone Tube Furnace Work?

What Types Of Tube Furnaces Are Available?

What Are The Advantages Of Using A Rotary Tube Furnace?

What Are The Advantages Of Using A Split Tube Furnace?

How Does A Vertical Tube Furnace Work?

What Are The Advantages Of Using A Multi-zone Tube Furnace?

What Temperature Ranges Can Tube Furnaces Achieve?

What Temperature Can A Rotary Tube Furnace Reach?

What Temperature Can A Split Tube Furnace Reach?

What Types Of Vertical Tube Furnaces Are Available?

What Types Of Multi-zone Tube Furnaces Are Available?

Can Tube Furnaces Operate Under Different Atmospheres?

What Types Of Materials Can Be Processed In A Rotary Tube Furnace?

Why Is The Split Design Beneficial In A Tube Furnace?

Why Choose A Vertical Tube Furnace Over A Horizontal One?

What Makes KINTEK Tube Furnaces Special?

What Temperature Ranges Can Vertical Tube Furnaces Achieve?

Are Vertical Tube Furnaces Customizable?

4.9 / 5

Incredible precision and durability! This furnace exceeded all my expectations.

4.8 / 5

Fast delivery and top-notch quality. A must-have for any lab!

4.7 / 5

The temperature control is flawless. Worth every penny!

4.9 / 5

Highly advanced technology. Perfect for high-temperature experiments.

4.8 / 5

Superb build quality and excellent performance. Very reliable!

4.7 / 5

Easy to set up and use. The quartz tube is a great addition.

4.9 / 5

Outstanding value for money. This furnace is a game-changer!

4.8 / 5

Consistent performance at extreme temperatures. Highly recommended!

4.7 / 5

The alumina tube option is fantastic for high-heat applications.

4.9 / 5

Speedy delivery and impeccable quality. Very impressed!

4.8 / 5

Robust construction and precise temperature control. A lab essential!

4.7 / 5

The furnace heats up quickly and maintains stability. Love it!

4.9 / 5

Cutting-edge technology with reliable results. Perfect for research.

4.8 / 5

Great investment for any laboratory. The quality is unmatched.

4.7 / 5

The furnace is built to last. Excellent performance every time.

4.9 / 5

Fast shipping and outstanding product. Exceeded all expectations!

4.8 / 5

The temperature uniformity is impressive. A fantastic purchase.

4.7 / 5

User-friendly and highly efficient. Perfect for high-temperature needs.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

Vertical Laboratory Quartz Tube Furnace Tubular Furnace

Precision KINTEK Vertical Tube Furnace: 1800℃ heating, PID control, customizable for labs. Ideal for CVD, crystal growth & materials testing.

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision high-temperature processing up to 2000°C for labs. Ideal for material synthesis, CVD, and sintering. Customizable options available.

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

KINTEK Laboratory Rotary Furnace: Precision heating for calcination, drying, sintering. Customizable solutions with vacuum & controlled atmosphere. Enhance research now!

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

2200°C Tungsten Vacuum Furnace for high-temperature materials processing. Precise control, superior vacuum, customizable solutions. Ideal for research & industrial applications.

Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Precision rotary tube furnace for continuous vacuum processing. Ideal for calcination, sintering, and heat treatment. Customizable up to 1600℃.

1700℃ High Temperature Muffle Oven Furnace for Laboratory

KT-17M Muffle Furnace: High-precision 1700°C lab furnace with PID control, energy efficiency, and customizable sizes for industrial & research applications.

2200 ℃ Graphite Vacuum Heat Treat Furnace

2200℃ Graphite Vacuum Furnace for high-temperature sintering. Precise PID control, 6*10⁻³Pa vacuum, durable graphite heating. Ideal for research & production.

1700℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-17A Controlled Atmosphere Furnace: Precise 1700°C heating with vacuum & gas control. Ideal for sintering, research & material processing. Explore now!

1400℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-14A Controlled Atmosphere Furnace for labs & industry. 1400°C max temp, vacuum sealing, inert gas control. Customizable solutions available.

1200℃ Controlled Inert Nitrogen Atmosphere Furnace

KINTEK 1200℃ Controlled Atmosphere Furnace: Precision heating with gas control for labs. Ideal for sintering, annealing, and material research. Customizable sizes available.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

Advanced PECVD Tube Furnace for precise thin film deposition. Uniform heating, RF plasma source, customizable gas control. Ideal for semiconductor research.

Related Articles

Mastering the Micro-Environment: The Art and Science of the Laboratory Tube Furnace

Explore how laboratory tube furnaces master thermal processing by controlling temperature, atmosphere, and geometry for advanced material synthesis.

Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

Discover the hidden reason your high-temperature experiments fail. It's not your process; it's a material mismatch inside your furnace. Learn how to fix it.

Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

Struggling with inconsistent results from your tube furnace? Discover why standard equipment fails and how a modular, customizable approach is key to success.

The Physics of Mismatched Tools: Why a Tube Furnace Isn't for Wastewater

A tube furnace is for precise material synthesis, not bulk water treatment. Understand the physics of heat capacity to choose the right environmental tech.

The Art of Isolation: Mastering Material Properties with Tube Furnaces

Tube furnaces excel not by merely heating, but by isolating samples in a controlled atmosphere, enabling precise thermal processing for advanced materials.

Mastering the Void: How Tube Furnaces Forge the Atoms of Innovation

Explore how tube furnaces create pristine, controlled environments, essential for the atomic-level precision in semiconductor and battery manufacturing.

The Geometry of Control: Why Tube Furnaces Define Modern Materials

Tube furnaces are more than ovens; they create the controlled environments essential for innovation in semiconductors, batteries, and new materials.

The Controlled Universe: Why Tube Furnaces Prioritize Precision Over Scale

Explore the psychology of thermal processing. A tube furnace is a deliberate choice for control over scale, creating a pure environment for high-stakes research.

Mastering the Void: How Tube Furnaces Engineer Predictable Outcomes

A tube furnace offers more than heat; it provides a controlled universe for material synthesis, ensuring process repeatability and predictable outcomes.

Beyond Heat: The Physics of Control in a Tube Furnace

A tube furnace provides ultimate control over heat and atmosphere, transforming material science. Discover how its design masters thermal uniformity.

More Than a Hot Box: The Art and Science of Configuring a Split Tube Furnace

Learn how to configure a split tube furnace by balancing thermal needs, dimensions, and atmosphere control to avoid costly over-specification.

A War Against Chaos: The Elegant Engineering of the Modern Tube Furnace

A furnace isn't just a heater; it's a system that battles entropy. Explore the physics of converting electricity to precise, uniform thermal energy.