Tube Furnace

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Item Number : KT-TF12

Price varies based on specs and customizations

- Max. temperature

- 1200℃

- Furnace tube diameter

- 30~230 mm

- Heating zone length

- 300~800 mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD/MPCVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Have a specific need? Contact us to discuss your custom furnace solution.

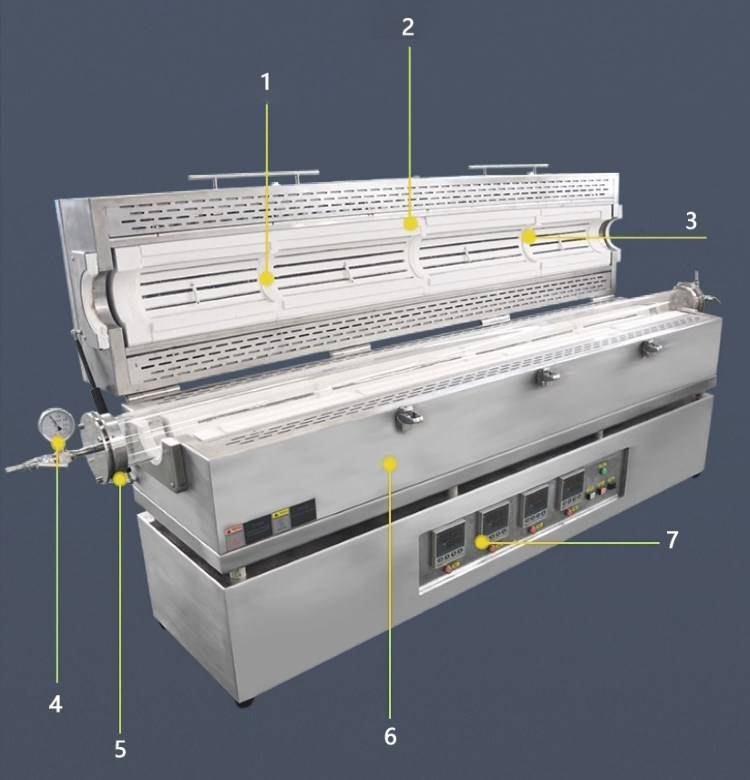

Product Details & Visuals

Explore the design and components of our 1200℃ Split Tube Furnace:

The surface is electrostatically sprayed for a luxurious and beautiful finish; the furnace shell adopts a double-layer air-cooled structure, ensuring the surface temperature remains ≤50°C. The opening and closing furnace door, furnace body, and control cabinet are integrated into a compact design. The control panel layout is rational and user-friendly. Furnace tube material and length can be customized according to your heat treatment material.

Introducing the 1200℃ Split Tube Furnace with Quartz Tube

The KINTEK 1200℃ Split Tube Furnace with Quartz Tube is a premier high-temperature laboratory solution engineered for precise heat treatment in controlled inert atmospheres. It features a programmable temperature controller with 30 segments, enabling heating and cooling rates up to 15°C per minute. Designed for operations up to 1200°C, this furnace system includes essential accessories like a vacuum pump and alumina ceramic end plugs to ensure uniform temperature distribution. It's an ideal choice for research and testing applications demanding meticulously controlled environments and high-temperature capabilities.

Technical Specifications

| Furnace model | KT-TF12 |

| Max. temperature | 1200℃ |

| Constant work temperature | 1100℃ |

| Furnace tube material | High purity quartz |

| Furnace tube diameter | 30 / 40 / 60 / 80 / 100 / 120 /150 / 230 mm |

| Heating zone length | 300 / 450 / 600 / 800 mm |

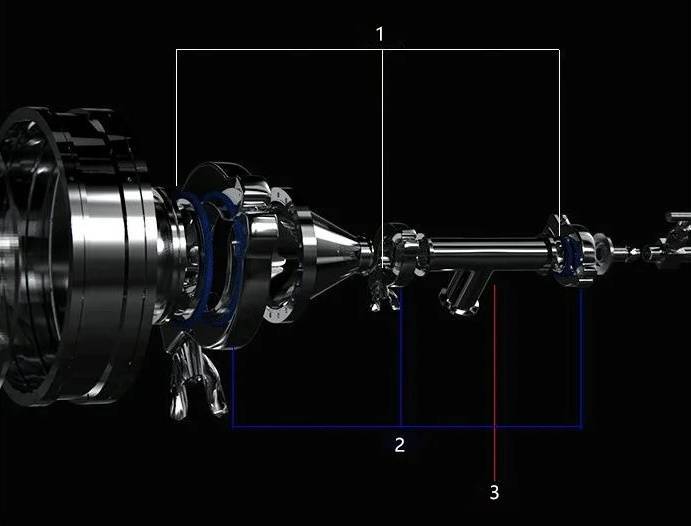

| Vacuum sealing solution | SS 304 flange with O ring |

| Rated vacuum pressure | 0.001Pa/10E5 torr |

| Rated positive pressure | 0.02Mpa/150 torr |

| Chamber material | Japan alumina fiber |

| Heating element | Cr2Al2Mo2 wire coil |

| Heating rate | 0-20℃/min |

| Temperature sensor | Build in K type thermal couple |

| Temperature controller | Digital PID controller/Touch screen PID controller |

| Temperature control accuracy | ±1℃ |

| Temperature uniformity | ±5℃ |

| Electric power supply | AC110-220V,50/60HZ |

| Other quartz tube sizes and heating zone lengths can be customized. Inquire about customization options. | |

Key Features & Benefits

Our 1200℃ Split Tube Furnace offers significant advantages for your laboratory and industrial applications:

- High-Temperature Capability: Operates reliably up to 1200°C, perfect for crystal growth, sintering, and advanced material testing.

- Durable Quartz Tube: Utilizes a high-purity quartz tube (softening point 1270°C) for excellent thermal stability and prolonged use at high temperatures.

- User-Friendly Split Design: The split furnace design allows for easy sample loading/unloading, minimizes thermal shock risk, and boosts operational efficiency.

- Optimized Reaction Efficiency: Thoughtfully designed tube length and diameter provide longer residence times and superior heat transfer for enhanced reaction uniformity and efficiency.

- Versatile Functionality: Ideal for diverse processes such as CVD, ceramic substrate conductivity testing, and nanostructure growth, making it invaluable in material science and engineering.

- Precision PID Temperature Control: Equipped with a 30-segment PID controller for accurate, consistent heating profiles crucial for complex experiments. The KT-TF12 Pro model features a 7-inch TFT touch screen for intuitive program setting and historical data analysis.

- Compact and Efficient Design: More compact than traditional furnaces with a smaller footprint, ideal for space-constrained environments and easier transport.

- Enhanced Observation: The top-open furnace shell design facilitates easy observation of samples within the quartz tube.

- Superior Sealing: Stainless steel vacuum flanges with various adapting ports ensure excellent sealing for high vacuum applications.

- Customizable: We can tailor features like quartz plate pore sizes and tube dimensions to perfectly match your sample types and research needs. Let's build your ideal furnace.

Applications

KINTEK tube furnaces are trusted across various sectors for both research and industrial tasks, including:

- Universities and research institutes for cutting-edge studies

- Industrial and mining enterprises for quality control and process development

- New material research and synthesis

- Chemical vapor deposition (CVD) processes

- Small sample vacuum sintering

- High-temperature pyrolysis experiments

- Material composition analysis

- General and specialized heating treatment work

Safety Advantages

Prioritizing your safety and equipment integrity:

- Over-Current and Over-Temperature Protection: The furnace automatically shuts off power if over-current or over-temperature conditions are detected.

- Thermocouple Failure Detection: Built-in thermocouple detection halts heating and triggers an alarm if a break or failure is identified.

- Power Failure Restart (KT-TF12 Pro): The KT-TF12 Pro model can resume the heating program automatically when power is restored after an outage.

- Cool-Touch Surface: Double furnace shell design with forced air cooling keeps the furnace surface temperature at or below 50°C during operation.

Operating Principle

The 1200℃ Split Tube Furnace employs a high-purity quartz tube as the heating chamber. A programmable PID temperature controller precisely regulates heating and cooling rates. The furnace is designed for inert atmosphere applications, supporting vacuum and gas purging to establish and maintain specific environmental conditions essential for sensitive material processing.

Standard Package

| No. | Description | Quantity |

| 1 | Furnace | 1 |

| 2 | Quartz tube | 1 |

| 3 | Vacuum flange | 2 |

| 4 | Tube thermal block | 2 |

| 5 | Tube thermal block hook | 1 |

| 6 | Heat resistant glove | 1 |

| 7 | Operation manual | 1 |

Optional Setup & Customization

Enhance your furnace's capabilities with these optional features. KINTEK excels in providing customized solutions to meet your specific experimental needs.

- In-tube gas detection and monitoring (e.g., H2, O2)

- Independent furnace temperature monitoring and recording systems

- RS 485 communication port for PC remote control and data exporting

- Gas feeding flow rate control (mass flowmeters and float flowmeters)

- Advanced touch screen temperature controller with versatile, user-friendly functions

- High vacuum pump station setups (e.g., vane vacuum pump, molecular pump, diffusion pump)

Interested in these options or have other specific requirements? Contact our technical team to explore the possibilities and receive a personalized quotation.

Ready to advance your research with a KINTEK high-temperature furnace? Request a quote or schedule a consultation with our furnace experts today!

Trusted by Industry Leaders

FAQ

What Are The Common Applications Of A Split Tube Furnace?

What Is A Tube Furnace And How Does It Work?

What Is The Principle Of A Hot Press Furnace?

What Are The Main Applications Of A Rotary Tube Furnace?

What Are The Main Applications Of Multi-zone Tube Furnaces?

What Is A Dental Furnace Used For?

What Are The Key Features Of A Split Tube Furnace?

What Are The Main Applications Of Tube Furnaces?

What Are The Applications Of A Hot Press Furnace?

What Are The Key Features Of A Rotary Tube Furnace?

What Are The Key Features Of Multi-zone Tube Furnaces?

What Are The Key Features Of A Dental Furnace?

How Does A Split Tube Furnace Work?

What Are The Advantages Of Using A Tube Furnace?

What Are The Features Of A Hot Press Furnace?

How Does A Rotary Tube Furnace Work?

How Does A Multi-zone Tube Furnace Work?

How Does A Dental Furnace Work?

What Are The Advantages Of Using A Split Tube Furnace?

What Types Of Tube Furnaces Are Available?

Why Is A Vacuum Environment Used In Hot Press Furnaces?

What Are The Advantages Of Using A Rotary Tube Furnace?

What Are The Advantages Of Using A Multi-zone Tube Furnace?

What Are The Advantages Of Using A Dental Furnace?

What Temperature Can A Split Tube Furnace Reach?

What Temperature Ranges Can Tube Furnaces Achieve?

What Materials Are Commonly Processed In Hot Press Furnaces?

What Temperature Can A Rotary Tube Furnace Reach?

What Types Of Multi-zone Tube Furnaces Are Available?

What Safety Features Should A Dental Furnace Have?

Why Is The Split Design Beneficial In A Tube Furnace?

Can Tube Furnaces Operate Under Different Atmospheres?

What Types Of Materials Can Be Processed In A Rotary Tube Furnace?

What Types Of Dental Furnaces Are Available?

What Makes KINTEK Tube Furnaces Special?

4.8 / 5

Incredible precision and durability! The quartz tube furnace exceeded my expectations. Perfect for lab use.

4.7 / 5

Fast delivery and top-notch quality. This furnace is a game-changer for our research projects.

4.9 / 5

Worth every penny! The split tube design makes it so easy to use. Highly recommend for any lab.

4.8 / 5

Superb craftsmanship and advanced tech. The furnace heats up quickly and maintains temperature flawlessly.

4.9 / 5

Impressive performance! The quartz tube is sturdy and the furnace is incredibly efficient. Love it!

4.7 / 5

Great value for money. The furnace arrived promptly and works like a charm. Very satisfied!

4.8 / 5

Reliable and high-quality. The split tube feature is brilliant. Perfect for high-temperature experiments.

4.9 / 5

Exceptional product! The furnace is robust and the quartz tube is crystal clear. A must-have for labs.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision high-temperature processing up to 2000°C for labs. Ideal for material synthesis, CVD, and sintering. Customizable options available.

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

KINTEK Laboratory Rotary Furnace: Precision heating for calcination, drying, sintering. Customizable solutions with vacuum & controlled atmosphere. Enhance research now!

Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Precision rotary tube furnace for continuous vacuum processing. Ideal for calcination, sintering, and heat treatment. Customizable up to 1600℃.

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

Vertical Laboratory Quartz Tube Furnace Tubular Furnace

Precision KINTEK Vertical Tube Furnace: 1800℃ heating, PID control, customizable for labs. Ideal for CVD, crystal growth & materials testing.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

Advanced PECVD Tube Furnace for precise thin film deposition. Uniform heating, RF plasma source, customizable gas control. Ideal for semiconductor research.

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

Precision Vacuum Press Furnace for labs: ±1°C accuracy, 1200°C max, customizable solutions. Boost research efficiency today!

2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

2200°C Tungsten Vacuum Furnace for high-temperature materials processing. Precise control, superior vacuum, customizable solutions. Ideal for research & industrial applications.

Vacuum Induction Melting Furnace

Explore KINTEK's Vacuum Induction Melting Furnace for high-purity metal processing up to 2000℃. Customizable solutions for aerospace, alloys, and more. Contact us today!

1800℃ High Temperature Muffle Oven Furnace for Laboratory

KINTEK Muffle Furnaces: Precision 1800°C heating for labs. Energy-efficient, customizable, with PID control. Ideal for sintering, annealing, and research.

1200℃ Muffle Oven Furnace for Laboratory

KINTEK KT-12M Muffle Furnace: Precision 1200°C heating with PID control. Ideal for labs needing rapid, uniform heat. Explore models & customization options.

Related Articles

More Than a Hot Box: The Art and Science of Configuring a Split Tube Furnace

Learn how to configure a split tube furnace by balancing thermal needs, dimensions, and atmosphere control to avoid costly over-specification.

The Bottleneck is the Cooldown: How Split Tube Furnaces Redefine Lab Efficiency

Discover how the split design in tube furnaces tackles the hidden bottleneck of cooldown time, boosting lab throughput and protecting delicate samples.

The Unsung Hero of the Lab: The Deliberate Design of the Single-Zone Split Tube Furnace

Explore the single-zone split tube furnace's design: how its split-hinge offers unmatched access while its single zone ensures thermal uniformity.

The Physics of Mismatched Tools: Why a Tube Furnace Isn't for Wastewater

A tube furnace is for precise material synthesis, not bulk water treatment. Understand the physics of heat capacity to choose the right environmental tech.

Mastering the Micro-Environment: The Deceptively Simple Genius of a Tube Furnace

A tube furnace isn't just an oven; it's a tool for precise environmental control. Its true value lies in isolating a sample from the world.

The Physics of Control: Mastering the Three-Stage Journey of Heat in a Tube Furnace

Master thermal processes by understanding heat's three-stage journey—radiation, convection, and conduction—and how furnace design dictates results.

Mastering the Void: How Tube Furnaces Forge the Atoms of Innovation

Explore how tube furnaces create pristine, controlled environments, essential for the atomic-level precision in semiconductor and battery manufacturing.

The Alchemy of Control: Mastering Material Properties with High-Temperature Tube Furnaces

Discover how tube furnaces enable material transformation by precisely controlling heat, atmosphere, and time—the keys to repeatable science.

The Geometry of Precision: Why a Tube Furnace's Design Is Its Greatest Strength

Discover how a tube furnace's compact design isn't just space-saving—it's the key to superior thermal uniformity and operational efficiency.

The Controlled Universe: Mastering Temperature and Atmosphere in a 70mm Tube Furnace

A tube furnace is not just an oven; it's a controlled environment where mastering thermal uniformity and atmosphere is key to repeatable science.

Mastering the Micro-Environment: The Unseen Power of the Tube Furnace

Explore how the tube furnace's true value lies not in heat, but in its ability to create a controlled environment for materials science.

The Art of Isolation: Mastering Material Properties with Tube Furnaces

Tube furnaces excel not by merely heating, but by isolating samples in a controlled atmosphere, enabling precise thermal processing for advanced materials.