The Search for a Perfect, Tiny Universe

In materials science, progress is a battle against variables. A stray oxygen molecule can ruin a semiconductor. A temperature fluctuation of a few degrees can render a superalloy brittle. The goal is often to create a small, perfect, and predictable universe where a material can be born or transformed without the chaotic interference of the outside world.

This isn't just a technical challenge; it's a psychological one. We need certainty. We need to know that our results are a consequence of our design, not random chance.

This is where the tube furnace transcends its role as a simple heater. Its true purpose is to be that tiny, controlled universe. Its value isn't just its heat, but its order.

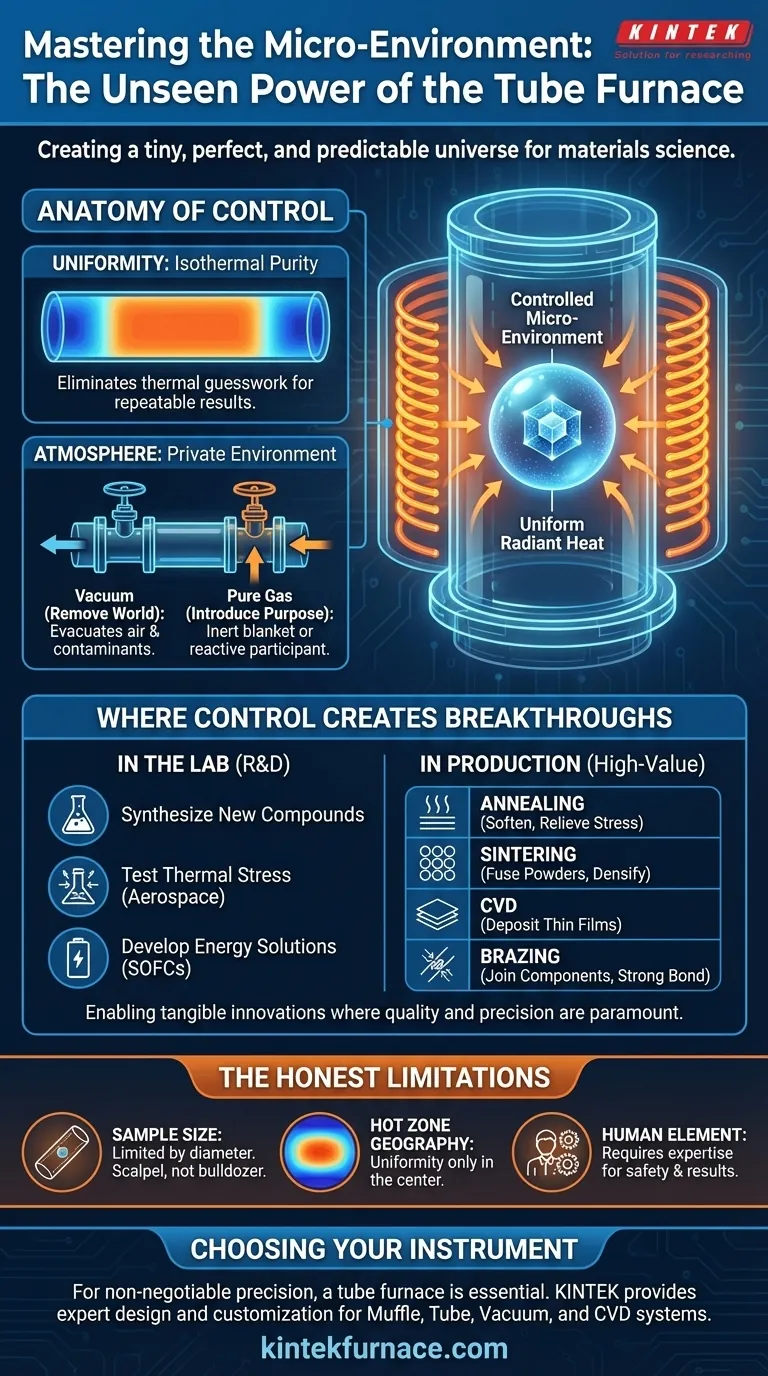

The Anatomy of Control

The elegant simplicity of a tube furnace—a cylindrical chamber surrounded by heating elements—is deceptive. This design is a masterclass in creating environmental certainty.

Uniformity: The Quest for Isothermal Purity

The cylindrical heating chamber provides even, radiant heat. This isn't just about getting hot; it's about getting hot uniformly. For a researcher annealing a delicate crystal or an engineer sintering a ceramic part, this uniformity means every part of the sample experiences the exact same thermal journey. It eliminates thermal guesswork, ensuring the process is repeatable and reliable.

Atmosphere: Crafting a Private Environment

The sealed tube is the key to absolute atmospheric control. It allows us to do two critical things:

- Remove the World: By pulling a vacuum, we can evacuate the air, with its reactive oxygen and unpredictable moisture. We create a clean slate, free from environmental contaminants.

- Introduce the Purpose: Into this vacuum, we can introduce a specific, pure gas. An inert gas like argon acts as a protective blanket, preventing oxidation. A reactive gas can be introduced to become a participant in a chemical reaction, like in chemical vapor deposition (CVD).

The furnace becomes a vessel for crafting the perfect atmosphere, tailored to the specific needs of the material.

Where Control Creates Breakthroughs

This mastery over temperature and atmosphere is not an abstract benefit. It is the enabling factor behind tangible innovations in the lab and on the production line.

In the Lab: From Theory to Tangible Matter

Imagine a team developing new battery materials. They need to synthesize a novel cathode powder under a pure argon atmosphere at 800°C for exactly six hours. The tube furnace provides the pristine, oxygen-free environment necessary for the chemical reaction to occur as designed. Any deviation could compromise the material's electrochemical performance.

This is the daily work of R&D. Tube furnaces are the workhorses for:

- Synthesizing new compounds and crystals.

- Testing how materials withstand thermal stress for aerospace applications.

- Developing next-generation energy solutions like solid oxide fuel cells (SOFCs).

In Production: Scaling Precision, Not Just Size

Consider the manufacturing of a specialized medical implant. The components are joined through brazing in a vacuum furnace to ensure the joint is perfectly clean and strong. Or think of the protective, ultra-hard coating on a machine tool, applied via CVD, where precursor gases react on the heated surface inside a tube furnace.

These are not mass-production scenarios. They are high-value processes where quality and precision are paramount. Key industrial applications include:

| Process | Goal | Why Control is Critical |

|---|---|---|

| Annealing | Soften metals, relieve internal stress | Prevents oxidation, ensures even grain structure |

| Sintering | Fuse powders into a solid mass | Precise temperature profile dictates final density/strength |

| CVD | Deposit a thin film or coating | Gas flow and temperature control the coating's quality |

| Brazing | Join components with a filler metal | A vacuum or inert gas ensures a strong, uncontaminated bond |

The Honest Limitations of a Specialist Tool

Like any specialized instrument, a tube furnace is not a universal solution. Understanding its boundaries is key to using it effectively.

The Paradox of Scale

The tube's diameter inherently limits sample size. This makes it perfect for research, prototyping, and small-batch production of high-value items, but unsuitable for high-volume manufacturing. It's a scalpel, not a bulldozer.

The Geography of Heat

Perfect temperature uniformity exists only within a defined "hot zone" in the center of the tube. The temperature naturally tapers off toward the ends. Successful processing requires understanding this thermal map and placing samples accordingly.

The Human Element

Operating a furnace with vacuum systems and reactive gases demands expertise. It is a powerful tool that requires a knowledgeable operator to ensure safety, repeatability, and the integrity of the results.

Choosing Your Instrument of Control

Ultimately, the decision to use a tube furnace comes down to a single question: How much control do you need?

If your work involves discovering new materials, optimizing a delicate thermal process, or manufacturing specialized components where precision is non-negotiable, then a tube furnace is not just an option—it's essential.

For those pushing the boundaries of what's possible, a standard furnace often isn't enough. You need a system built for your specific challenge. This is where expert design and customization, like the Muffle, Tube, Vacuum, and CVD systems developed by KINTEK, become critical. They provide not just the heat, but the finely-tuned control required for your next breakthrough.

When your research or production demands a perfect, tiny universe of your own making, we can help you build it. Contact Our Experts

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

Related Articles

- The Geometry of Progress: Why the 70mm Tube Furnace is a Laboratory Cornerstone

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube

- A War Against Chaos: The Elegant Engineering of the Modern Tube Furnace

- Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

- Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research