Picture this: weeks of meticulous sample preparation have led to this moment. You carefully place your advanced ceramic material into the tube furnace, set the controller for that critical 1450°C sintering cycle, and leave it to run overnight. The next morning, you don't return to a breakthrough, but to a disaster: a milky, cracked process tube, a contaminated sample, and a furnace that won't heat. Weeks of work, valuable materials, and your project timeline—all shattered.

If this scenario feels painfully familiar, you're not alone.

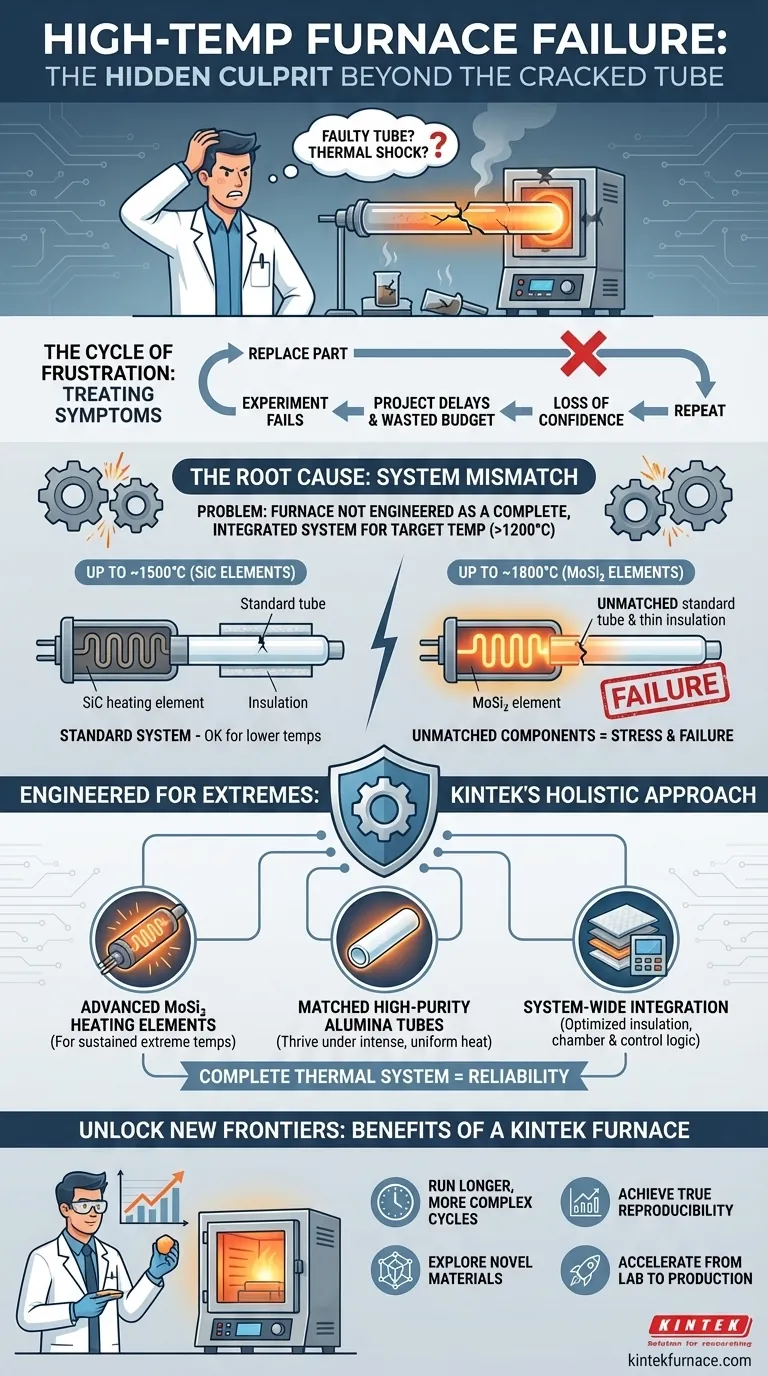

The Cycle of Frustration: Why Replacing Parts Isn't the Answer

In laboratories pushing the boundaries of materials science, unexpected furnace failure above 1200°C is a common and costly story. The typical reaction is to troubleshoot the most obvious point of failure. You might think:

- "It must have been a faulty alumina tube. Let's order a new one."

- "Maybe there was thermal shock. We'll try a slower ramp rate next time."

- "Let's just run the next experiment at 1350°C to be safe."

While logical, these are merely guesses that treat the symptom, not the disease. Each failed experiment isn't just a scientific setback; it's a significant business problem. It leads to project delays, wasted R&D budgets, and a critical loss of confidence in your experimental data, potentially compromising product quality down the line. The cycle repeats, and the true source of the problem remains hidden.

The Root Cause: It's Not a Faulty Part, It's a System Mismatch

The recurring failures aren't due to a single bad component. The problem is more fundamental: the furnace itself was likely not engineered as a complete, integrated system for the temperatures you're trying to achieve.

Operating a furnace above 1200°C is not just about generating more heat; it's a different world of materials science. The components that work perfectly at 1100°C will catastrophically fail at 1500°C or 1700°C.

The core of the issue lies in the relationship between the heating elements and everything around them.

A Tale of Two Heating Elements

- For temperatures up to ~1500°C: Furnaces use Silicon Carbide (SiC) heating elements. These are robust workhorses, but they have a definitive operational ceiling.

- For temperatures up to ~1800°C: Pushing into this upper echelon requires a complete material shift to Molybdenum Disilicide (MoSi₂) elements. These are advanced ceramics capable of withstanding extreme thermal loads where SiC would simply degrade.

Here is the critical insight: the choice of heating element dictates the design of the entire furnace. A furnace built with MoSi₂ elements isn't just a standard furnace with "hotter" elements swapped in. To function reliably, it requires a different grade of high-purity alumina tubing, denser multi-layer insulation, and a power control system all precisely matched to the unique properties of MoSi₂.

This is why simply replacing a cracked tube in an improperly specified furnace is a temporary fix for a permanent problem. The tube didn't fail in isolation; it failed because the entire thermal system—the elements, the insulation, the chamber geometry—was creating stresses it wasn't designed to handle.

Engineered for Extremes: The Anatomy of a Truly Reliable Furnace

To permanently solve this problem, you don't need a better component; you need a better-designed system. A true high-temperature furnace is an instrument where every part is selected and integrated based on a deep understanding of these underlying physical principles.

This is precisely where KINTEK's design philosophy makes the difference. We don't just assemble parts; we engineer holistic thermal solutions.

When you require a furnace for 1700°C applications, we don't just sell you a box with a high-temperature rating. We build a system founded on the right core components:

- Advanced MoSi₂ Heating Elements: We start with the correct element material designed for sustained, stable operation at extreme temperatures.

- Matched High-Purity Alumina Tubes: The process tubes we provide are specified to not just survive, but thrive under the intense, uniform heat generated by our element configuration, ensuring chemical inertness and structural integrity.

- System-Wide Integration: Our exceptional R&D and in-house manufacturing allow us to control every variable. The insulation density, chamber dimensions, and temperature control logic are all optimized to work in concert, eliminating the "system mismatch" that causes component failure in the first place.

Our deep customization capability means we build the furnace your experiment truly demands, ensuring every component is perfectly suited for your specific process parameters.

Beyond Reliability: Unlocking New Frontiers in Your Research

When your furnace is no longer a source of uncertainty, a remarkable shift happens. You stop spending time troubleshooting equipment and start focusing entirely on your research.

With a reliable, system-engineered KINTEK furnace, you can now:

- Run Longer, More Complex Cycles: Perform extended sintering, annealing, or crystal growth processes with confidence, knowing the temperature will remain stable and the equipment secure.

- Achieve True Reproducibility: Generate consistent, reliable data from one experiment to the next, accelerating your discovery and development timeline.

- Explore Novel Materials: Confidently work with materials that require the most extreme and stable thermal environments, opening up new avenues of innovation.

- Accelerate from Lab to Production: Develop processes with the assurance that the results can be reliably scaled, reducing time-to-market for new technologies.

Your research is too important to be derailed by equipment limitations. Instead of battling a furnace that works against you, it's time to partner with experts who understand the materials science behind building one that works for you. Let's discuss the specific thermal challenges of your project and engineer a solution that turns possibility into reality. Contact Our Experts.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Related Articles

- The Art of Isolation: Mastering Material Properties with Tube Furnaces

- Mastering the Void: How Tube Furnaces Engineer Predictable Outcomes

- Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

- Mastering the Void: How Tube Furnaces Forge the Atoms of Innovation

- The Physics of Mismatched Tools: Why a Tube Furnace Isn't for Wastewater