Atmosphere Furnace

1400℃ Controlled Inert Nitrogen Atmosphere Furnace

Item Number : KT-14A

Price varies based on specs and customizations

- Max. temperature

- 1400℃

- Chamber material

- Japan alumina fiber

- Heating element

- Silicon Carbide (SiC)

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introducing the KT-14A Controlled Atmosphere Furnace

The KT-14A Controlled Atmosphere Furnace, featuring advanced heating chamber overall vacuum sealing technology, is an ideal atmosphere furnace for both demanding laboratory research and robust industrial applications.

It features a heavy-duty vacuum chamber structure design for enhanced durability, excellent sealing performance to maintain precise atmospheric conditions, and a scientific united control panel for intuitive management of vacuum suction, inert gas pressure, and flow.

Operators will appreciate the versatile 7-inch TFT smart touch screen controller. This modern interface allows for easy setting and saving of different heating programs, significantly reducing the complexity associated with traditional digital controllers and aiding in the comprehensive analysis of historical operational data.

Detailed Views & Components

Explore the craftsmanship and design of the KT-14A:

Why KINTEK for Your High-Temperature Furnace Solutions?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and industrial clients with advanced high-temperature furnace solutions. Our extensive product line, including Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces (like the KT-14A featured here), and specialized CVD/PECVD/MPCVD Systems, is engineered to meet the most rigorous experimental demands.

Your Unique Requirements, Our Custom Solutions: At KINTEK, we pride ourselves on our strong deep customization capability. If the standard specifications of the KT-14A don't perfectly align with your project, or if you require unique features for your experiments, our experienced engineering team is ready to collaborate with you. We specialize in tailoring our furnace solutions to precisely meet your unique experimental requirements, ensuring you get the perfect tool for your work.

Ready to discuss your specific needs or explore customization options? Contact our furnace experts today!

KT-14A Controlled Atmosphere Furnace: In-Depth

Operating Principle

The KT-14A Controlled Atmosphere Furnace utilizes a vacuum sealing technique for its heating chamber. The insulation chamber and heating elements are enclosed within a reinforced vacuum chamber, resembling the design of a vacuum glove box. A vacuum pump is employed to evacuate the air within the chamber, creating a negative pressure of -0.1Mpa (relative to atmosphere). Inert gas is then introduced to establish a controlled atmosphere environment. Essential components include a vacuum pressure gauge, vacuum suction port with valve, gas purging port with valve, and a float flowmeter. This furnace is suitable for both laboratory and industrial applications where precise atmospheric control is paramount.

Key Features

The KT-14A is designed for advanced heat treatment processes, offering features that enhance functionality, efficiency, and safety:

- Double Layer Housing and Wind Cooling System: The furnace features a double-layer housing with an integrated wind cooling system. This design facilitates rapid heating and cooling cycles, improving operational efficiency while maintaining low surface temperatures for enhanced operator safety.

- Sealed Housing and Atmosphere Control: With a meticulously sealed housing, silicon gel sealed cover, and a door equipped with a silicon gel gasket, the furnace maintains an exceptionally tight seal. This is crucial for processes requiring precise controlled atmospheres. A water cooling system (if applicable, or ensure consistency with specs) and gas flow management through flow meters ensure accurate control over the chamber environment.

- Versatile Atmosphere Handling: The furnace is capable of pre-vacuuming to remove ambient air and can handle a variety of process gases including H2, Ar, N2, O2, CO, and NH3. Multiple gas inlets and outlets, along with a burning mouth for exhaust gases, allow for complex atmosphere manipulations essential for advanced materials processing.

- Advanced Insulation and Heating Elements: Utilizing high-quality Silicon Carbide (SiC) heating elements and a polycrystalline Japan alumina fibre chamber, the furnace ensures optimal temperature uniformity and energy efficiency. This robust construction supports high-temperature applications up to 1400°C.

Advantages

The Controlled Atmosphere Furnace offers significant benefits for demanding applications:

- Uniform Temperature Field: Ensures consistent temperature distribution throughout the chamber (typically ±5℃ in the defined uniform zone), critical for precise and repeatable heat treatment processes like sintering and operations in reducing atmospheres.

- Low Surface Temperature: Despite high internal operating temperatures, the furnace's exterior remains relatively cool, enhancing safety and reducing the risk of burns or accidental fires, thanks to its double-layer housing and wind cooling system.

- Rapid Heating and Cooling: The efficient wind cooling system and high-performance heating elements allow for quick temperature adjustments (heating rate 0-20℃/min, adjustable), optimizing the efficiency of processes and reducing downtime.

- Advanced Temperature Control: Equipped with a Digital PID controller (or optional Touch screen PID controller), the furnace supports programmable segments (e.g., 40 segments with Shimaden FP93 if specified), providing precise (±1℃ accuracy) and flexible control over complex heating profiles.

- Versatile Atmosphere Control: Designed to handle multiple gases (H2, Ar, N2, O2, CO, NH3) and can be pre-vacuumed to -0.1Mpa, enabling a wide range of heat treatment processes in inert, reducing, or oxidizing atmospheres.

- Sealed and Safe Design: Features such as a silicon gel sealed cover, a sealed door with a silicon gel gasket, and robust construction ensure the furnace maintains a tight seal, preventing atmosphere leakage and ensuring process integrity.

- Durable and High-Quality Materials: The chamber is constructed from Japan alumina fiber, known for its resistance to high temperatures and thermal shock, ensuring the longevity and reliability of the furnace.

Safety Advantages

- The Kindle Tech controlled atmosphere furnace is equipped with over-current protection and over-temperature alarming functions. In the event of such an occurrence, the furnace will automatically shut off power.

- The furnace incorporates a built-in thermocouple detecting function. If a thermocouple breaks or fails, heating will stop, and an alarm will activate.

- The KT-14A Pro model (if applicable, or specify if standard) supports a power failure restarting function. The furnace will automatically resume its heating program once power is restored after an outage.

Applications

The KT-14A Controlled Atmosphere Furnace is a versatile and efficient tool designed for various high-temperature processes requiring precise atmosphere control. This furnace is ideal for applications in industrial settings, scientific research institutes, and universities. Its ability to pre-vacuum and handle gases like H2, Ar, N2, O2, CO, and NH3 makes it suitable for a range of specialized processes:

- Atmosphere Protection Sintering: Ideal for sintering materials under controlled atmospheres to prevent oxidation, ensure phase purity, and enhance final material properties.

- Atmosphere Reducing Processes: Widely used in processes that require a reducing environment (e.g., presence of H2 or CO) for applications like metal oxide reduction or specific alloy formation.

- Material Research and Development: Essential for researchers studying the effects of controlled atmospheres on material synthesis, phase transformations, and property evolution.

- Small Batch Production: Particularly useful in the production of sensitive materials such as semiconductors, advanced ceramics (e.g., silicon nitride), and other components where atmosphere control is critical for quality and yield.

- Educational Purposes: Provides invaluable hands-on experience for students in materials science, chemistry, and engineering, demonstrating the practical principles and applications of controlled atmosphere furnaces.

Technical Specifications

| Furnace model | KT-14A | ||

|---|---|---|---|

| Max. temperature | 1400℃ | ||

| Constant work temperature | 1300℃ | ||

| Vacuum pressure | -0.1Mpa (relative to atmosphere) | ||

| Vacuum valve | Needle valve | ||

| Chamber material | Japan alumina fiber | ||

| Heating element | Silicon Carbide (SiC) | ||

| Heating rate | 0-20℃/min (adjustable) | ||

| Temperature sensor | S-type thermocouple | ||

| Temperature controller | Digital PID controller / Optional Touch screen PID controller | ||

| Temperature control accuracy | ±1℃ | ||

| Temperature uniformity | ±5℃ (in defined uniform zone) | ||

| Electric power supply | AC110-220V, 50/60HZ (configurable) | ||

| Standard Chamber Sizes (Custom sizes available) | |||

| Chamber size (WxDxH mm) | Effective volume (L) | Chamber size (WxDxH mm) | Effective volume (L) |

| 100x100x100 | 1 | 300x300x400 | 36 |

| 150x150x150 | 3.4 | 400x400x400 | 64 |

| 150x150x200 | 4.5 | 500x500x500 | 125 |

| 200x200x200 | 8 | 600x600x600 | 216 |

| 200x200x300 | 12 | 800x800x800 | 512 |

| Custom designed sizes and volumes are accepted. Contact us with your specific dimensional requirements. | |||

Standard Package

| No. | Description | Quantity |

|---|---|---|

| 1 | Controlled Atmosphere Furnace (KT-14A) | 1 unit |

| 2 | Thermal block(s) / Hearth plate | 1 set |

| 3 | Crucible tong | 1 piece |

| 4 | Heat resistant gloves | 1 pair |

| 5 | Operation manual | 1 copy |

Optional Setup & Customization

Further tailor the KT-14A to your precise needs with these optional upgrades and KINTEK's customization services:

- Independent furnace temperature monitoring and recording system (e.g., paperless recorder)

- RS 485 communication port for PC remote control, data logging, and exporting

- Additional or specialized insert gas ports, exhaust output ports, or an observation window port on the furnace door

- Upgrade to the versatile 7-inch TFT smart touch screen PID controller with advanced programming and data analysis functions (if not standard on your chosen configuration)

- Integration with vacuum pumps or gas mixing systems

Don't see an option listed or have a unique process requirement? KINTEK excels in creating bespoke furnace solutions. Contact our engineering team today to discuss your specific experimental needs, and let us design and build the perfect controlled atmosphere furnace for your application.

FAQ

What Is An Atmosphere Furnace Used For?

What Is The Principle Of A Hot Press Furnace?

What Are The Key Features Of An Atmosphere Furnace?

What Are The Applications Of A Hot Press Furnace?

How Does An Atmosphere Furnace Work?

What Are The Features Of A Hot Press Furnace?

What Are The Advantages Of Using An Atmosphere Furnace?

Why Is A Vacuum Environment Used In Hot Press Furnaces?

What Types Of Gases Can Be Used In An Atmosphere Furnace?

What Materials Are Commonly Processed In Hot Press Furnaces?

What Safety Features Are Available In Advanced Atmosphere Furnaces?

4.9 / 5

Incredible precision and durability! Perfect for high-temperature experiments. Worth every penny.

4.8 / 5

Fast delivery and top-notch quality. This furnace exceeded all my expectations!

4.7 / 5

The nitrogen control is flawless. A game-changer for our lab’s research!

4.9 / 5

Robust build and advanced tech. Highly recommend for serious metallurgical work.

4.8 / 5

Superb value for money. The temperature consistency is unmatched.

4.9 / 5

Arrived sooner than expected. Performance is stellar—no regrets!

4.7 / 5

Reliable and efficient. Handles extreme heat like a champ.

4.8 / 5

Cutting-edge technology. Our lab’s productivity has skyrocketed!

4.9 / 5

Exceptional build quality. The inert atmosphere control is perfection.

4.8 / 5

Easy to operate and maintain. A solid investment for any lab.

4.7 / 5

Fast heating and precise control. Exactly what we needed!

4.9 / 5

Outstanding performance. The nitrogen system is incredibly stable.

4.8 / 5

Durable and high-tech. Delivered on time and works flawlessly.

4.7 / 5

Great for advanced materials testing. Highly efficient and reliable.

4.9 / 5

Perfect for high-precision applications. The build is rock-solid.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

Discover KINTEK's Hydrogen Atmosphere Furnace for precise sintering & annealing in controlled environments. Up to 1600°C, safety features, customizable.

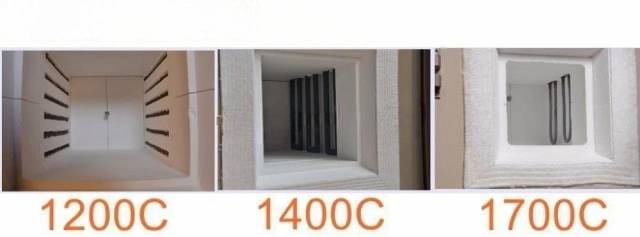

1700℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-17A Controlled Atmosphere Furnace: Precise 1700°C heating with vacuum & gas control. Ideal for sintering, research & material processing. Explore now!

1200℃ Controlled Inert Nitrogen Atmosphere Furnace

KINTEK 1200℃ Controlled Atmosphere Furnace: Precision heating with gas control for labs. Ideal for sintering, annealing, and material research. Customizable sizes available.

Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

KINTEK Mesh Belt Furnace: High-performance controlled atmosphere furnace for sintering, hardening & heat treatment. Customizable, energy-efficient, precise temperature control. Get a quote now!

Vacuum Heat Treat Sintering and Brazing Furnace

KINTEK Vacuum Brazing Furnaces deliver precision, clean joints with superior temperature control. Customizable for diverse metals, ideal for aerospace, medical, and thermal applications. Get a quote!

Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

KINTEK's Vacuum Pressure Sintering Furnace offers 2100℃ precision for ceramics, metals, and composites. Customizable, high-performance, and contamination-free. Get a quote now!

600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

600T Vacuum Induction Hot Press Furnace for precise sintering. Advanced 600T pressure, 2200°C heating, vacuum/atmosphere control. Ideal for research & production.

Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

KINTEK's Vacuum Molybdenum Wire Sintering Furnace excels in high-temperature, high-vacuum processes for sintering, annealing, and material research. Achieve precise 1700°C heating with uniform results. Custom solutions available.

Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

Compact vacuum tungsten wire sintering furnace for labs. Precise, mobile design with superior vacuum integrity. Ideal for advanced material research. Contact us!

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!

1800℃ High Temperature Muffle Oven Furnace for Laboratory

KINTEK Muffle Furnaces: Precision 1800°C heating for labs. Energy-efficient, customizable, with PID control. Ideal for sintering, annealing, and research.

1400℃ Muffle Oven Furnace for Laboratory

KT-14M Muffle Furnace: Precision 1400°C heating with SiC elements, PID control, and energy-efficient design. Ideal for labs.

1200℃ Muffle Oven Furnace for Laboratory

KINTEK KT-12M Muffle Furnace: Precision 1200°C heating with PID control. Ideal for labs needing rapid, uniform heat. Explore models & customization options.

Laboratory Muffle Oven Furnace with Bottom Lifting

Boost lab efficiency with KT-BL Bottom Lifting Furnace: precise 1600℃ control, superior uniformity, and enhanced productivity for material science and R&D.

Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

KINTEK MPCVD Systems: Grow high-quality diamond films with precision. Reliable, energy-efficient, and beginner-friendly. Expert support available.

915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

KINTEK MPCVD Diamond Machine: High-quality diamond synthesis with advanced MPCVD technology. Faster growth, superior purity, customizable options. Boost production now!

Related Articles

Why Your High-Temp Experiments Fail: It’s Not the Heat, It’s the Atmosphere

Frustrated by inconsistent results? Discover why the furnace atmosphere, not just temperature, is the key to success in heat treatment and materials science.

Beyond Temperature: Mastering the Invisible Environment in a Tube Furnace

A deep dive into how a tube furnace's design masters precision by separating the heat source from a controlled, isolated sample environment.

More Than Heat: The Unseen Power of Atmosphere in Tube Furnaces

Discover why controlled atmosphere, not just high temperature, is the key to advanced material processing like annealing, sintering, and CVD.

Beyond Heat: The Unseen Power of Environmental Control in Tube Furnaces

Discover why the true value of a tube furnace isn't just temperature, but the absolute environmental control it offers for repeatable science.

The Alchemy of Isolation: Why Tube Furnaces Are Indispensable for Innovation

Explore how a tube furnace's true value lies not in heat, but in creating isolated, controlled environments for advanced materials science and innovation.

The Engineer's Gambit: Why Vacuum Furnaces Are About Control, Not Just Heat

Explore the physics and psychology behind vacuum furnaces, where eliminating atmospheric chaos enables surgically precise, repeatable heat treatment.

The Controlled Universe: Mastering Matter Inside a 70mm Tube Furnace

Explore how the tube furnace's precise control of temperature and atmosphere is fundamental to innovation in materials science, chemistry, and nanotech.

The Hidden Flaw in Your Heat Treatment: It’s Not the Temperature, It’s the Air

Discover why your heat-treated components fail despite perfect recipes. The root cause isn't temperature—it's the atmosphere. Learn how to fix it.

From Powder to Power: The Physics of Control in a Tube Furnace

Tube furnaces create superior glass and ceramics not just with heat, but through precise atmospheric control that prevents oxidation and enables advanced processes.

The Physics of Perfection: How Vacuum Furnaces Eliminate Metallurgical Uncertainty

Vacuum heat treatment offers more than a clean surface; it provides ultimate control by eliminating atmospheric variables, enhancing material integrity and process repeatability.

The Invisible Contaminant: Why Your Furnace Atmosphere is Sabotaging Your Results

Struggling with inconsistent results from your high-temp processes? Discover the hidden contaminant sabotaging your work and how to fix it for good.

Beyond Heat: The Art of Control in a Tube Furnace

Explore how tube furnaces provide the precise atmospheric and thermal control essential for advanced material synthesis, annealing, and sintering.