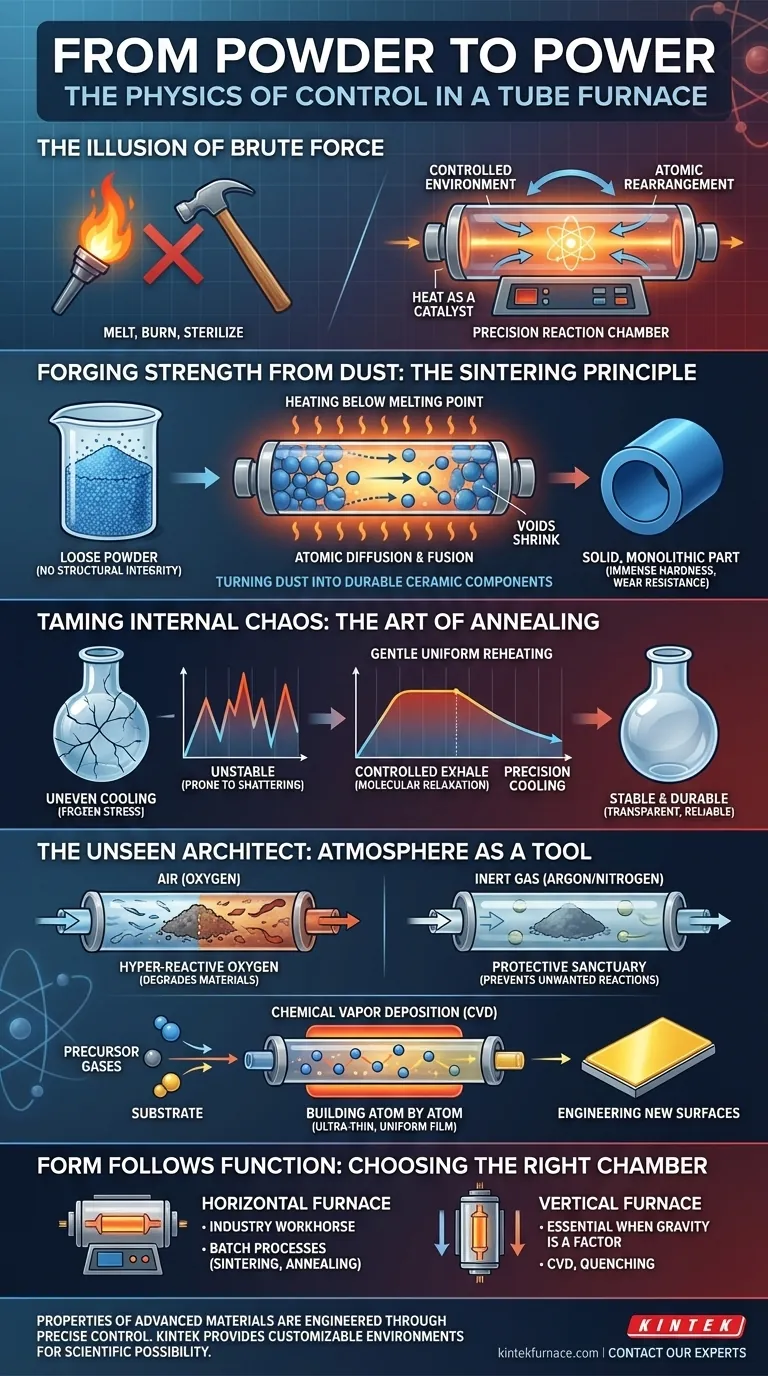

The Illusion of Brute Force

We tend to think of high temperature as a blunt instrument. A tool of brute force meant to melt, burn, or sterilize. In the world of material science, however, this couldn't be further from the truth.

Heat isn't the goal; it's the catalyst. The real work lies in creating a perfectly controlled environment where that heat can guide atoms to rearrange themselves into a stronger, more stable, or entirely new structure.

A tube furnace, then, is not merely an oven. It is a reaction chamber—a small, isolated universe where the fundamental properties of matter are re-engineered with intention.

Forging Strength from Dust: The Sintering Principle

The Psychology of a Powder

Consider a pile of fine ceramic powder. It is a substance full of potential, yet it has no structural integrity. It is a collection of individual particles, disconnected and fragile. You can pour it, but you cannot build with it. Its state is one of disorganization.

Sintering is the process of bringing order to this chaos. By heating the powder to a temperature just below its melting point, we provide the energy for a remarkable transformation to occur.

The Dance of Atoms

This isn't melting. It's a far more elegant process. The heat energizes the atoms, allowing them to diffuse across the boundaries of individual particles. The particles begin to fuse, the voids between them shrink, and the material's density skyrockets.

What was once a loose powder becomes a solid, monolithic part with immense hardness and wear resistance. This is how we turn dust into the durable ceramic components used in everything from aerospace to electronics.

Taming Internal Chaos: The Art of Annealing

Glass Is a Frozen River of Stress

When glass is formed, it cools unevenly. The surface solidifies while the interior remains molten, creating a hidden war of tension within the material. This internal stress makes the glass unstable, prone to shattering from a minor thermal shock or physical impact. It is a product waiting to fail.

Annealing is the art of brokering peace in this internal conflict.

A Controlled Exhale

The process involves gently reheating the glass to a uniform temperature, allowing its molecular structure to relax and settle. Then, it is cooled with extreme slowness and precision. This controlled exhale ensures no new stresses are introduced.

The result is a product that is not just transparent, but stable and durable. It’s the difference between a fragile object and a reliable component.

The Unseen Architect: Atmosphere as a Tool

The single most critical feature of a modern tube furnace is not its heating element, but its sealed process tube. This allows for absolute control over the gaseous environment, which is less a background condition and more an active tool.

Why Air Is the Enemy

At high temperatures, the oxygen in the air is not passive. It is a hyper-reactive agent, eager to bond with and alter your material. This oxidation can catastrophically degrade a material's electrical, mechanical, or optical properties.

By flushing the process tube with an inert gas like argon or nitrogen, we create a sanctuary. This protective atmosphere prevents unwanted chemical reactions, preserving the integrity of the material as it undergoes its thermal transformation.

Building Atom by Atom

This atmospheric control enables the pinnacle of material engineering: Chemical Vapor Deposition (CVD). Here, precursor gases are introduced into the heated tube, where they react and deposit an ultra-thin, highly uniform film onto a substrate.

With CVD, you are not just treating a material; you are constructing a new surface on it, one atomic layer at a time. This is how we create the super-hard, chemically resistant coatings that define high-performance components.

Form Follows Function: Choosing the Right Chamber

The physical design of a furnace is not an afterthought; it is dictated by the physics of the desired process.

- Horizontal Furnaces: The industry workhorse. Ideal for general-purpose batch processes like sintering and annealing where samples can be simply placed inside.

- Vertical Furnaces: Essential when gravity is a factor. Perfect for CVD, where gases must flow uniformly around a substrate, or for processes where a sample must be dropped into a quenching medium below.

Achieving these distinct physical and chemical transformations requires more than just a generic heat source. It demands an instrument engineered for a specific purpose. This is why a range of solutions—from versatile KINTEK Tube Furnaces for R&D to specialized CVD systems for advanced coatings—is essential. The geometry of the chamber must serve the goal of the material scientist.

The properties of advanced materials are not found; they are engineered. They are the deliberate outcome of exquisitely controlled processes that transform humble starting materials into components of incredible strength, stability, and function.

Whether you are sintering robust ceramics, annealing flawless optical glass, or pioneering next-generation coatings, the precision of your equipment dictates the quality of your results. At KINTEK, we provide the highly customizable, precisely controlled environments you need to turn scientific possibility into tangible reality. Contact Our Experts

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

Related Articles

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube

- The Art of Isolation: Mastering Material Properties with Tube Furnaces

- The Physics of Control: Mastering the Three-Stage Journey of Heat in a Tube Furnace

- Beyond Heat: The Unseen Power of Environmental Control in Tube Furnaces

- Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)