You’ve done everything right. The precursors are pure, the process gas is controlled, and the temperature profile is programmed to the decimal. You run the experiment, wait for hours, and open the furnace, only to find a cracked process tube or, worse, a contaminated sample. Weeks of work and valuable materials are wasted. If this cycle of promising starts and frustrating failures sounds familiar, you're not alone.

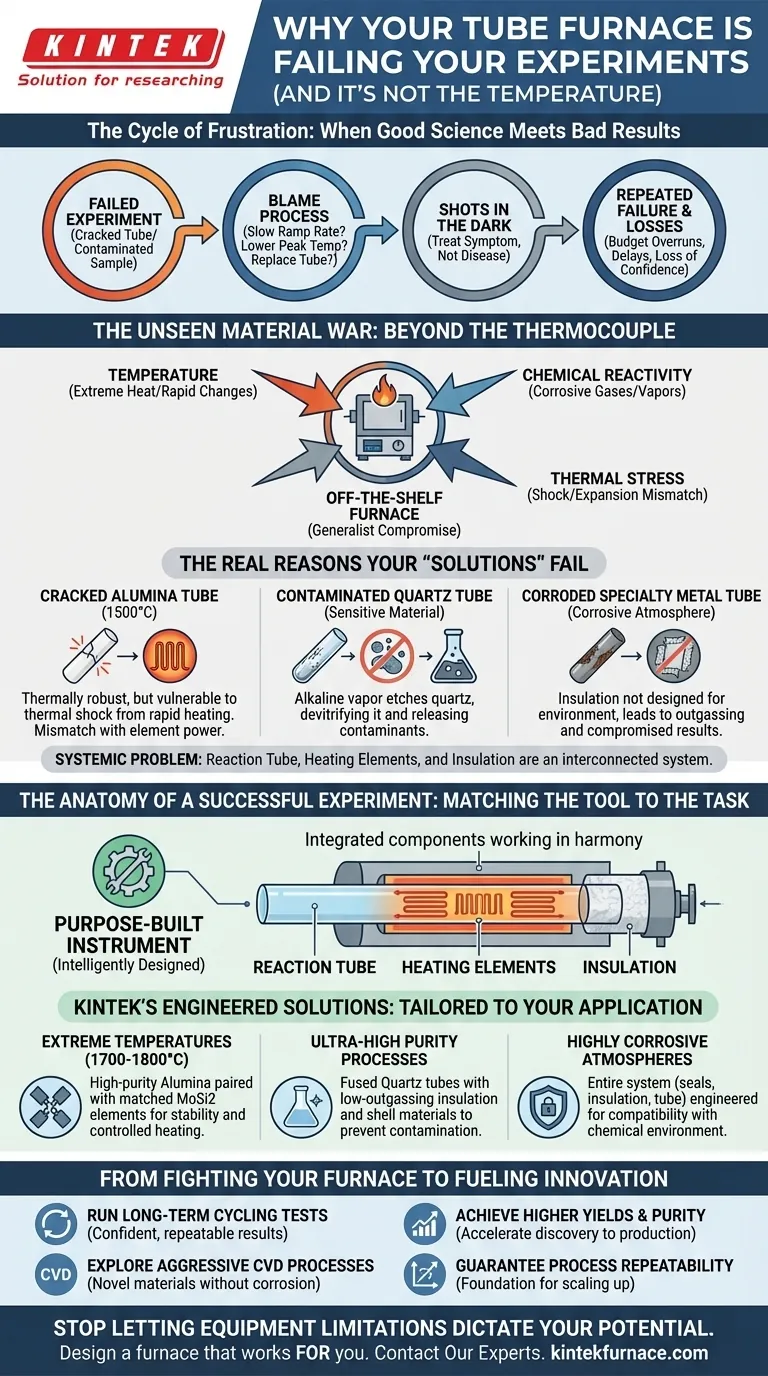

The Cycle of Frustration: When Good Science Meets Bad Results

This is a common, costly, and deeply frustrating problem in labs around the world. When an experiment fails, the immediate instinct is to blame the process. We start asking questions like:

- "Did we heat it up or cool it down too quickly?" So we slow the ramp rate, extending an already long process.

- "Was the temperature too high?" So we compromise, lowering the peak temperature and potentially sacrificing the quality of the final material.

- "Was it just a faulty tube?" So we order an identical replacement, unknowingly setting the stage for the exact same failure down the line.

These attempts are often just shots in the dark. They treat the symptom—a failed run—without diagnosing the disease. The business consequences are severe. Each failed experiment translates directly into budget overruns, delayed project timelines, and a loss of confidence in your R&D outcomes. When you can't trust your equipment to deliver repeatable results, you can't innovate effectively.

Beyond the Thermocouple: The Unseen Material War Inside Your Furnace

Here is the fundamental truth that is often overlooked: A tube furnace's success is not just about reaching a temperature; it's about surviving the journey. The root cause of most "mysterious" failures isn't your scientific process. It's a fundamental conflict between the materials your furnace is made of and the demands of your experiment.

Think of it as a three-way battle between Temperature, Chemical Reactivity, and Thermal Stress. An off-the-shelf furnace is a generalist, built on a series of compromises. Its materials are not specifically chosen for your unique application.

The Real Reasons Your "Solutions" Fail

Let's revisit those common struggles through this lens:

- The Cracked Alumina Tube: You need to work at 1500°C. Alumina is rated for 1700°C, so it should be fine, right? Not necessarily. While it's thermally robust, it can be vulnerable to severe thermal shock. If your heating elements are designed for speed and you don't have precise ramp control, you can easily exceed the material's stress limits. Slowing the ramp helps, but it doesn't solve the core mismatch between the element's power and the tube's tolerance.

- The Contaminated Sample in a Quartz Tube: You're working with a sensitive material and chose a high-purity quartz tube. But during your process at 1000°C, a slightly alkaline vapor is produced. Over several hours, this vapor begins to slowly etch the quartz, devitrifying it and releasing contaminants into your sample. The failure wasn't the heat; it was a slow, invisible chemical attack.

- The Corroded Specialty Metal Tube: You wisely chose a molybdenum tube to handle a corrosive atmosphere, but the experiment failed. The hidden culprit? The insulation package wasn't designed to handle the furnace's new chemical environment, leading to outgassing that compromised your results.

The problem is systemic. The reaction tube, the heating elements, and the insulation are an interconnected system. A weakness in one component, or a mismatch between them, leads to total system failure.

The Anatomy of a Successful Experiment: Matching the Tool to the Task

To break the cycle of failure, you don't need to change your science. You need a tool that is intelligently designed to support it. The solution is a furnace where the selection of every core material is a deliberate answer to the challenges of your specific application.

This is precisely where an engineered solution becomes critical. At KINTEK, we don't start a conversation by asking "What temperature do you need?" We start by asking "What are you trying to achieve?"

Our deep customization capability is built on the understanding that the materials must work in harmony:

- For Extreme Temperatures (up to 1700-1800°C): We pair high-purity Alumina tubes not with just any heating element, but with precisely matched Molybdenum Disilicide (MoSi2) elements. This synergy allows for both high thermal stability and controlled, rapid heating rates without risking tube integrity.

- For Ultra-High Purity Processes: We select Fused Quartz tubes and ensure the surrounding insulation and furnace shell materials are also low-outgassing, protecting your experiment from every potential source of contamination.

- For Highly Corrosive Atmospheres: We go beyond simply providing a specialty metal tube. We engineer the entire system—from seals to insulation—to be compatible with your specific chemical environment, ensuring that the furnace itself doesn't become a variable in your experiment.

A KINTEK furnace isn't just an assembly of parts. It's a purpose-built instrument, designed from the ground up to eliminate the material conflicts that cause experiments to fail.

From Fighting Your Furnace to Fueling Your Innovation

When your furnace transforms from an unpredictable variable into a reliable and consistent tool, everything changes. The resources once spent on re-running failed experiments and troubleshooting equipment are freed. You stop fighting your furnace and start focusing on what truly matters: pushing the boundaries of your research.

With a furnace perfectly tailored to your process, you can:

- Run long-term cycling tests with confidence, knowing the tube won't degrade after the tenth, or hundredth, cycle.

- Explore aggressive chemical vapor deposition (CVD) processes to create novel materials without fear of corroding your equipment.

- Achieve higher yields and sample purity, accelerating your path from discovery to publication or production.

- Guarantee process repeatability, which is the bedrock of scaling up from the lab to pilot manufacturing.

In short, the right tool removes limitations and opens up new avenues for discovery.

Stop letting equipment limitations dictate your research potential. Our team of experts is ready to go beyond simple specs to understand your unique process challenges and design a furnace that works for you, not against you. Let's discuss how to build the reliable foundation for your next breakthrough. Contact Our Experts.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

Related Articles

- Beyond Heat: The Physics of Control in a Tube Furnace

- The Controlled Universe: Why Tube Furnaces Prioritize Precision Over Scale

- Mastering the Void: How Tube Furnaces Engineer Predictable Outcomes

- Mastering the Void: How Tube Furnaces Forge the Atoms of Innovation

- The Physics of Mismatched Tools: Why a Tube Furnace Isn't for Wastewater