CVD & PECVD Furnace

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

Item Number : KT-CTF14

Price varies based on specs and customizations

- Max. temperature

- 1400℃

- Heating zone

- 2x450mm

- Temperature control accuracy

- ±1℃

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Discover KINTEK's Advanced Multi-Zone CVD Tube Furnaces

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our Multi-Zone CVD Tube Furnaces are engineered for precision, reliability, and adaptability, empowering your research and production processes.

Product Showcase: Multi-Heating Zones CVD Tube Furnace

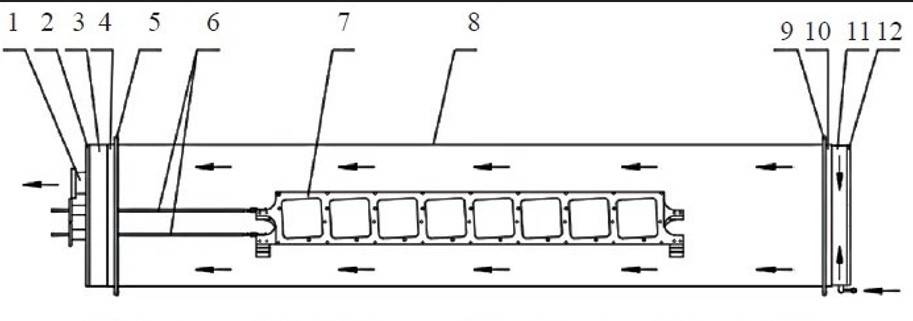

Schematic diagram of the typical reaction chamber structure of tubular PECVD equipment 1. Exhaust hole;2. Tail end flange;3. Tail water cooling flange;4. Tail sealing flange;5. Tail fixing flange;6. Electrode rod;7. Graphite boat;8. Quartz furnace tube;9. Front fixing flange;10. Front water cooling flange;11. Front air inlet flange;12. Furnace door

What is a Multi-Zone CVD Tube Furnace?

A multi-zone Chemical Vapor Deposition (CVD) tube furnace is specialized laboratory equipment designed for depositing thin films on substrates through chemical reactions of gases or vapors. The critical advantage of "multi-zone" design lies in its multiple, independently controlled heating zones. This allows for precise manipulation of the temperature profile within the furnace, a crucial factor for many CVD processes as temperature directly influences the properties of the deposited film. These furnaces are indispensable for both cutting-edge research and development and demanding production applications.

Why Choose KINTEK's Multi-Zone CVD Furnaces?

KINTEK's Multi-Zone CVD Tube Furnaces are engineered to deliver superior performance and adaptability for your critical processes. Here’s how we empower your work:

- Unmatched Temperature Precision: Independent heating zones allow for the creation of extended constant temperature fields or precisely controlled temperature gradients, essential for uniform deposition and specialized material synthesis.

- Advanced Process Control: PID programmable temperature control ensures excellent accuracy. Coupled with remote and centralized control capabilities, you gain flexibility and ease of monitoring.

- Stable and Accurate Gas Delivery: High-accuracy MFC (Mass Flow Controller) mass flowmeters ensure precise and stable gas supply speeds, including options for pre-mixing source gases, vital for consistent film quality.

- Reliable High-Vacuum Environment: Robust stainless steel vacuum flanges with various adapting ports ensure excellent sealing, achieving and maintaining high vacuum degrees necessary for sensitive CVD processes.

- User-Friendly Operation & Data Analysis: Select models, like the KT-CTF14 Pro, feature a 7-inch TFT touch screen controller, simplifying program setting and enabling easy analysis of historical data.

- Versatility for Diverse Applications: Our furnaces are not limited to CVD; they are also ideal for diffusion, annealing, sintering, and other thermo-treatments under vacuum or controlled atmospheres.

- Energy-Efficient Design: Featuring high-quality ceramic fiber insulation and a double-layer structure, our furnaces minimize heat loss, reducing external temperatures and saving energy.

- Durable and Customizable Materials: Furnace tubes are available in various materials like heat-resistant steel, high-purity quartz glass, and ceramics to suit diverse chemical environments and temperature requirements.

Principle of Operation

The Multi-Heating Zones CVD Tube Furnace utilizes the chemical vapor deposition (CVD) process to deposit thin films onto substrates. Gaseous precursors, typically metal-organic compounds and/or hydrides, are introduced into the furnace chamber. These precursors react chemically at controlled temperatures to form a solid film material on the substrate. The furnace's multiple heating zones enable precise control over the deposition temperature and temperature gradient across the substrate, allowing for the deposition of high-quality films with tailored properties such as thickness, composition, and crystallinity. A vacuum system is integrated to remove impurities and control the deposition pressure, ensuring optimal process conditions.

Applications

Our Multi-Heating Zones CVD Tube Furnaces are widely used in various advanced fields, including:

- Chemical Vapor Deposition (CVD): Growth of thin films for electronic devices, semiconductors, solar cells, coatings, and nanomaterials.

- Diffusion: Precise doping of semiconductors and metals.

- Annealing: Heat treatment of materials to enhance their structural and physical properties.

- Sintering: Bonding of powdered materials through controlled heat and pressure to form solid structures.

- Thermo-treatments: A wide range of controlled heating and cooling processes for material research and modification.

- Element Analysis and Determination: Preparation of samples for analytical purposes.

- Material Processing: Quenching, annealing, and tempering of small steel pieces, development of electronic ceramics, and other new materials.

Technical Specifications

| Furnace model | KT-CTF14-60 |

|---|---|

| Max. temperature | 1400℃ |

| Constant work temperature | 1300℃ |

| Furnace tube material | High purity Al2O3 tube |

| Furnace tube diameter | 60mm |

| Heating zone | 2x450mm |

| Chamber material | Alumina polycrystalline fiber |

| Heating element | Silicon Carbide |

| Heating rate | 0-10℃/min |

| Thermal couple | S type |

| Temperature controller | Digital PID controller/Touch screen PID controller |

| Temperature control accuracy | ±1℃ |

| Gas precise control unit | |

| Flow meter | MFC mass flow meter |

| Gas channels | 4 channels |

| Flow rate | MFC1: 0-5SCCM O2 MFC2: 0-20SCMCH4 MFC3: 0- 100SCCM H2 MFC4: 0-500 SCCM N2 |

| Linearity | ±0.5% F.S. |

| Repeatability | ±0.2% F.S. |

| Pipe line and valve | Stainless steel |

| Maximum Operating Pressure | 0.45MPa |

| Flow meter controller | Digital Knob controller/Touch screen controller |

| Standard vacuum unit(Optional) | |

| Vacuum pump | Rotary vane vacuum pump |

| Pump flow rate | 4L/S |

| Vacuum suction port | KF25 |

| Vacuum gauge | Pirani/Resistance silicon vacuum gauge |

| Rated vacuum pressure | 10Pa |

| High vacuum unit(Optional) | |

| Vacuum pump | Rotary vane pump+Molecular pump |

| Pump flow rate | 4L/S+110L/S |

| Vacuum suction port | KF25 |

| Vacuum gauge | Compound vacuum gauge |

| Rated vacuum pressure | 6x10-5Pa |

| Above specifications and setups can be customized | |

Standard Package

| No. | Description | Quantity |

|---|---|---|

| 1 | Furnace | 1 |

| 2 | Quartz tube (or other material as per order) | 1 |

| 3 | Vacuum flange set | 2 |

| 4 | Tube thermal block | 2 |

| 5 | Tube thermal block hook | 1 |

| 6 | Heat resistant glove | 1 |

| 7 | Precise gas control unit (if ordered) | 1 |

| 8 | Vacuum unit (if ordered) | 1 |

| 9 | Operation manual | 1 |

Deep Customization for Your Unique Needs

KINTEK excels in providing deeply customized furnace solutions to precisely meet unique experimental and production requirements. Beyond our standard configurations, we offer a wide array of optional setups and modifications:

- In-tube gas detection and monitoring (e.g., H2, O2).

- Independent furnace temperature monitoring and recording systems.

- RS 485 communication port for PC remote control and data exporting.

- Versatile gas feeding flow rate control options, including various mass flowmeters and float flowmeters.

- Advanced touch screen temperature controllers with user-friendly interfaces and extensive programming capabilities.

- Comprehensive high vacuum pump station setups, incorporating vane vacuum pumps, molecular pumps, diffusion pumps, and more.

- Custom furnace dimensions, heating zone configurations, and material choices.

Tell us your challenge, and we'll engineer the solution.

Partner with KINTEK for Your High-Temperature Solutions

With a strong foundation in R&D and in-house manufacturing, KINTEK is dedicated to supplying laboratories worldwide with advanced high-temperature furnace systems, including Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and specialized CVD/PECVD/MPCVD Systems. Our commitment to deep customization ensures that you receive a furnace perfectly tailored to your specific experimental goals.

Ready to elevate your material processing and research capabilities? Discuss your requirements with our expert team.

Contact Us for a Custom Solution or Quote

Trusted by Industry Leaders

FAQ

What Is A Tube Furnace And How Does It Work?

What Are The Main Applications Of Multi-zone Tube Furnaces?

What Is A Vertical Tube Furnace?

What Is A Vacuum Induction Furnace?

What Are The Main Applications Of A Vacuum Furnace?

What Is An Atmosphere Furnace Used For?

What Are The Main Applications Of Tube Furnaces?

What Are The Key Features Of Multi-zone Tube Furnaces?

What Are The Applications Of A Vertical Tube Furnace?

What Are The Main Applications Of Vacuum Induction Furnaces?

What Are The Key Features Of A Vacuum Furnace?

What Are The Key Features Of An Atmosphere Furnace?

What Are The Advantages Of Using A Tube Furnace?

How Does A Multi-zone Tube Furnace Work?

What Are The Advantages Of A Vertical Tube Furnace?

How Does A Vacuum Induction Furnace Work?

How Does A Vacuum Furnace Work?

How Does An Atmosphere Furnace Work?

What Types Of Tube Furnaces Are Available?

What Are The Advantages Of Using A Multi-zone Tube Furnace?

How Does A Vertical Tube Furnace Work?

What Are The Advantages Of Using A Vacuum Induction Furnace?

What Are The Advantages Of Using A Vacuum Furnace?

What Are The Advantages Of Using An Atmosphere Furnace?

What Temperature Ranges Can Tube Furnaces Achieve?

What Types Of Multi-zone Tube Furnaces Are Available?

What Types Of Vertical Tube Furnaces Are Available?

What Types Of Vacuum Induction Furnaces Are Available?

What Types Of Materials Can Be Processed In A Vacuum Furnace?

What Types Of Gases Can Be Used In An Atmosphere Furnace?

Can Tube Furnaces Operate Under Different Atmospheres?

Why Choose A Vertical Tube Furnace Over A Horizontal One?

Why Is Temperature Control Important In Vacuum Induction Furnaces?

What Is The Difference Between Hot Wall And Cold Wall Vacuum Furnaces?

What Safety Features Are Available In Advanced Atmosphere Furnaces?

What Makes KINTEK Tube Furnaces Special?

What Temperature Ranges Can Vertical Tube Furnaces Achieve?

What Materials Can Be Processed In A Vacuum Induction Furnace?

Can Vacuum Furnaces Be Customized For Specific Applications?

Are Vertical Tube Furnaces Customizable?

How Does The Vacuum Environment Benefit Material Processing?

4.9 / 5

Incredible precision and control! The multi-zone heating is a game-changer for our lab.

4.8 / 5

Fast delivery and flawless setup. This furnace exceeded our expectations!

4.7 / 5

Worth every penny! The quality and durability are unmatched.

4.9 / 5

Top-notch technology. The temperature uniformity is perfect for our research.

4.8 / 5

Efficient and reliable. Our experiments have never been smoother.

4.7 / 5

Great value for money. The build quality is impressive.

4.9 / 5

A must-have for any serious lab. The performance is stellar.

4.8 / 5

Quick setup and easy to use. Highly recommend this furnace!

4.7 / 5

Durable and efficient. Perfect for high-temperature applications.

4.9 / 5

The multi-zone feature is revolutionary. Our productivity has soared.

4.8 / 5

Exceptional craftsmanship. This furnace is built to last.

4.7 / 5

Reliable and precise. A fantastic investment for any lab.

4.9 / 5

Cutting-edge technology. The temperature control is impeccable.

4.8 / 5

Fast shipping and excellent customer service. Very satisfied!

4.7 / 5

High-quality materials and superb performance. Highly recommend.

4.9 / 5

The best furnace we've used. The multi-zone heating is brilliant.

4.8 / 5

Perfect for our CVD needs. The machine is a workhorse.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

KINTEK Laboratory Rotary Furnace: Precision heating for calcination, drying, sintering. Customizable solutions with vacuum & controlled atmosphere. Enhance research now!

Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

High-performance SiC heating elements for labs, offering 600-1600°C precision, energy efficiency, and long lifespan. Customizable solutions available.

Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Precision rotary tube furnace for continuous vacuum processing. Ideal for calcination, sintering, and heat treatment. Customizable up to 1600℃.

Vacuum Hot Press Furnace Machine for Lamination and Heating

KINTEK Vacuum Lamination Press: Precision bonding for wafer, thin-film & LCP applications. 500°C max temp, 20-ton pressure, CE certified. Custom solutions available.

Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

Compact vacuum tungsten wire sintering furnace for labs. Precise, mobile design with superior vacuum integrity. Ideal for advanced material research. Contact us!

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Reliable CF/KF flange vacuum electrode feedthrough for high-performance vacuum systems. Ensures superior sealing, conductivity & durability. Customizable options available.

Vacuum Hot Press Furnace Machine Heated Vacuum Press

KINTEK Vacuum Hot Pressing Furnace: Precision heating & pressing for superior material density. Customizable up to 2800°C, ideal for metals, ceramics, and composites. Explore advanced features now!

Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

KF/ISO/CF ultra-high vacuum stainless steel flange pipe systems for precision applications. Customizable, durable, and leak-tight. Get expert solutions now!

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

KINTEK RF PECVD System: Precision thin-film deposition for semiconductors, optics & MEMS. Automated, low-temperature process with superior film quality. Custom solutions available.

Related Articles

Why Your Crystal Growth Experiments Are Failing: The Hidden Culprit in Your Tube Furnace

Struggling with inconsistent CVT results? Discover why your tube furnace's temperature gradient, not your chemistry, is the likely culprit and how to fix it.

How CVD Diamond Synthesis Methods Compare for Industrial Applications

Compare CVD diamond synthesis methods (HFCVD, DC Plasma Arc Jet, MPCVD) for cost, quality, and industrial applications like tools, optics, and quantum tech.

Mastering the Micro-Environment: The Deceptively Simple Genius of a Tube Furnace

A tube furnace isn't just an oven; it's a tool for precise environmental control. Its true value lies in isolating a sample from the world.

A War Against Chaos: The Elegant Engineering of the Modern Tube Furnace

A furnace isn't just a heater; it's a system that battles entropy. Explore the physics of converting electricity to precise, uniform thermal energy.

Mastering the Micro-Environment: The Art and Science of the Laboratory Tube Furnace

Explore how laboratory tube furnaces master thermal processing by controlling temperature, atmosphere, and geometry for advanced material synthesis.

The Alchemy of Isolation: Why Tube Furnaces Are Indispensable for Innovation

Explore how a tube furnace's true value lies not in heat, but in creating isolated, controlled environments for advanced materials science and innovation.

Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

Struggling with inconsistent results from your tube furnace? Discover why standard equipment fails and how a modular, customizable approach is key to success.

The Physics of Control: Mastering the Three-Stage Journey of Heat in a Tube Furnace

Master thermal processes by understanding heat's three-stage journey—radiation, convection, and conduction—and how furnace design dictates results.

The Alchemy of Control: Mastering Material Properties with High-Temperature Tube Furnaces

Discover how tube furnaces enable material transformation by precisely controlling heat, atmosphere, and time—the keys to repeatable science.

The Controlled Void: How Tube Furnaces Forge the Materials of Tomorrow

Discover why precise atmospheric and thermal control in tube furnaces, not just high heat, is the key to advanced materials research like CVD and nano-synthesis.

The Art of Isolation: Mastering Material Properties with Tube Furnaces

Tube furnaces excel not by merely heating, but by isolating samples in a controlled atmosphere, enabling precise thermal processing for advanced materials.

Mastering the Micro-Environment: The Unseen Power of the Tube Furnace

Explore how the tube furnace's true value lies not in heat, but in its ability to create a controlled environment for materials science.