Vacuum Hot Press Furnace

Spark Plasma Sintering SPS Furnace

Item Number : KTSP

Price varies based on specs and customizations

- Rated temperature

- Standard up to 1600°C (Customizable up to 2300℃ or higher based on requirements)

- Rated pressure

- 100KN (10 Ton) ~ 500KN (50 Ton)

- Sample size (Max. Die Diameter)

- Ø30mm ~ Ø200mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Explore KINTEK's Spark Plasma Sintering (SPS) Furnace

Discover the advanced capabilities and robust design of our Spark Plasma Sintering systems. KINTEK is committed to providing high-quality, customizable furnace solutions for your research and production needs.

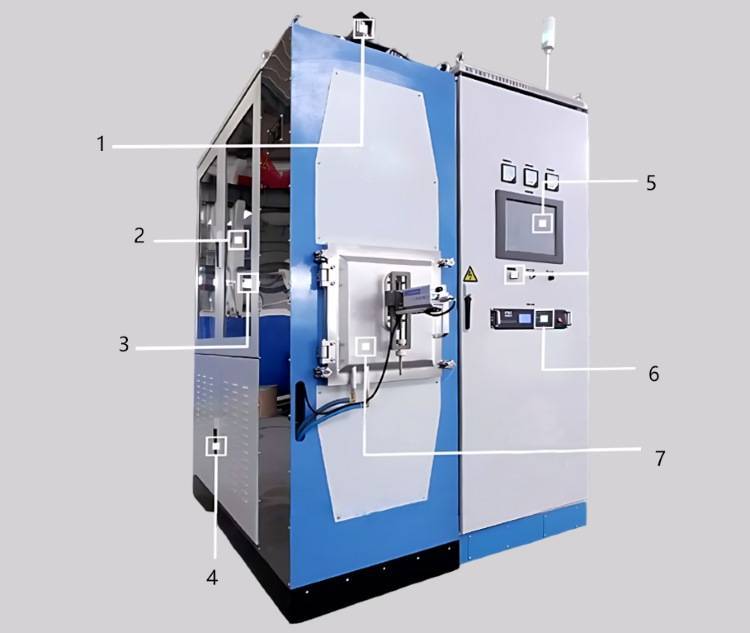

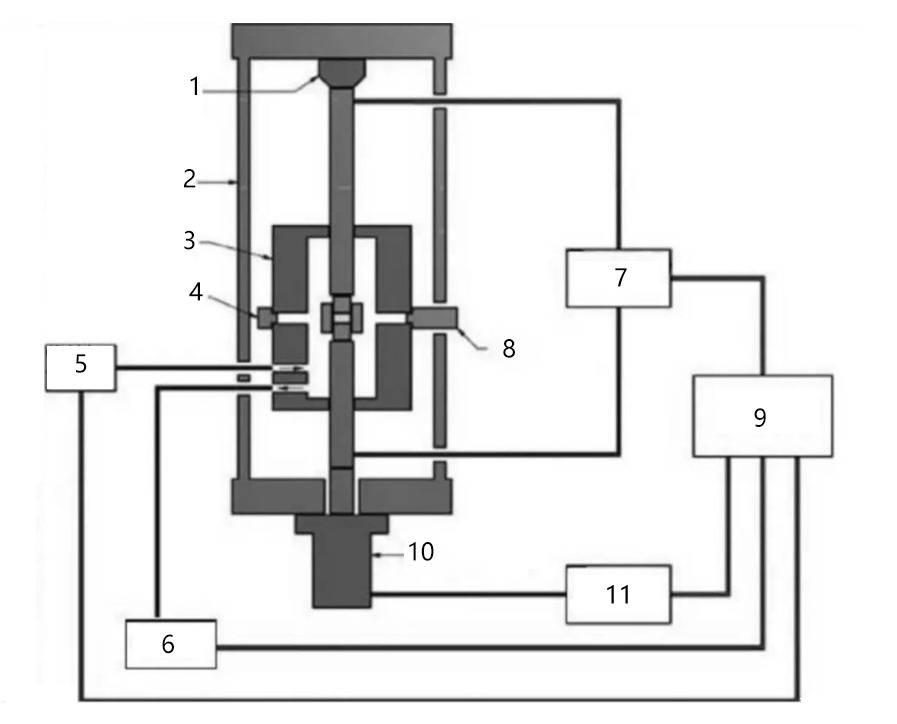

Detailed Views & Components

1. Loading unit 2. Loading frame 3. Vacuum chamber 4. Observation window 5. Inert gas channel 6. Vacuum pump 7. Pulse switch 8. Temperature meter 9. Control system 10. Hydraulic cylinder 11. Hydraulic system

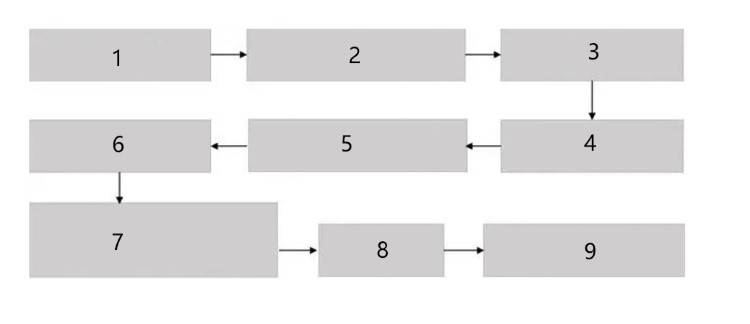

Process Flow of Spark Plasma Sintering: (1. Select appropriate mold 2. Calculate the required powder mass 3. Fill the mold 4. Apply pressure 5. Place in plasma sintering 6. Static pressure molding 7. Computer adjust sintering parameters plasma rapid sintering 8. Sample finished product 9. Performance testing and research)

Introduction to Spark Plasma Sintering (SPS) and KINTEK Solutions

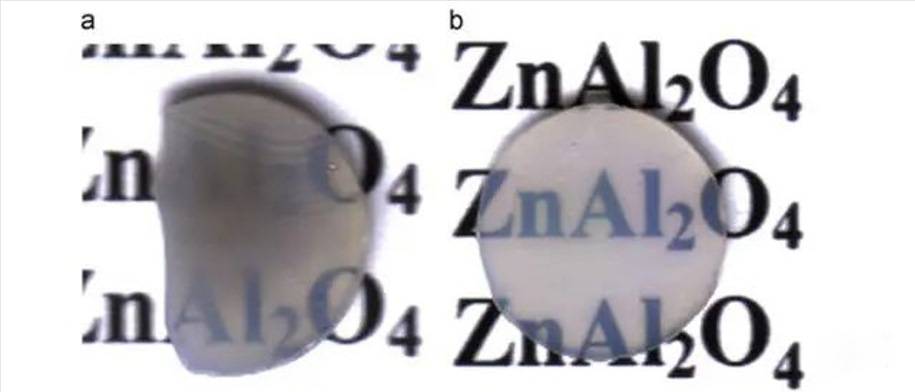

Spark Plasma Sintering (SPS) is a revolutionary, rapid material preparation method that utilizes pulsed current to sinter materials directly within a mold. This advanced technique combines plasma activation, hot pressing, and resistance heating, offering significant advantages over traditional sintering methods. SPS technology facilitates uniform heating, achieves high heating rates, operates at low sintering temperatures with short sintering times, and boasts high production efficiency. It also purifies material surfaces, inhibits grain growth, and aids in producing uniform, controllable microstructures. Compared to conventional sintering, SPS is an environmentally friendly, cost-effective solution requiring minimal operation time.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD/MPCVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Our Spark Plasma Sintering Furnaces are a testament to this commitment, designed to empower your material innovation.

The Principle Behind Spark Plasma Sintering

Spark Plasma Sintering (SPS) functions by passing a pulse current directly through the sintering mold and the powder particles or bulk samples contained within. This process uniquely combines several mechanisms:

- Joule Heating: The primary heating mechanism is the Joule heat generated by the electrical current flowing through the sample and mold.

- Plasma Activation: The pulsed current can create spark discharges between adjacent particles. This ionizes gas molecules, generating plasma (positrons and electrons) that purifies and activates particle surfaces. This activation promotes material migration, significantly reducing the required sintering temperature and time.

- Rapid Processing: The high energy density provided by the pulse current voltage enables rapid sintering and effective dispersion of discharge points. This unique heating mode also facilitates rapid cooling within the crystal structure, which is crucial for preparing high-quality amorphous and nano-materials.

Key Features & Benefits of KINTEK's SPS Furnaces

KINTEK's Spark Plasma Sintering Furnaces are engineered to provide a cutting-edge solution for the rapid and efficient sintering of a wide array of materials, including metals, ceramics, and composites. Our furnaces employ a unique pressure sintering method using on-off DC pulse currents to generate discharge plasma, discharge impact pressure, Joule heat, and electric field diffusion, all of which significantly enhance the sintering process. Here’s how our features deliver exceptional value:

- Achieve Consistent, High-Quality Results with Automated Program Control: Our SPS furnaces incorporate an advanced control system that automates critical parameters like sintering temperature, pressure, and current. This precision automation ensures reproducible sintering conditions, reduces manual intervention, saves valuable operator time, and minimizes the risk of human error, leading to more reliable and consistent material properties.

- Enhanced Operational Safety: Your safety and equipment integrity are paramount. Our SPS furnaces are equipped with a comprehensive safety shutdown function. The system automatically powers down if it detects abnormal conditions such as excessive water temperatures, mold damage, or other emergencies. This proactive safety feature protects both the equipment and operators, fostering a secure working environment.

- Optimize Your Processes with Advanced Data Acquisition & Analysis: Gain deep insights into your sintering processes. Our furnaces include a sophisticated data acquisition system that meticulously records and analyzes critical parameters, including sintering voltage, current, control temperature, applied pressure, displacement, and vacuum degree. This allows for detailed process tracking, enabling you to optimize sintering conditions for superior product quality and R&D advancements.

- Simplified Operation via User-Friendly Interface: Navigate and control the sintering process with ease. A large LCD touch operation panel provides real-time diagnostics and status updates, including displacement data, interlock status, alarm displays, and pressurization settings. This intuitive interface simplifies operation and maintenance, empowering operators to manage the sintering process effectively and efficiently.

- Superior Sintered Products with High-Pressure Graphite Mold: The robust graphite mold system allows for high-pressure sintering, significantly enhancing the density, uniformity, and overall quality of your sintered products. The mold is intelligently designed with a through-hole for thermocouple insertion, enabling precise and real-time temperature monitoring directly at the sample during the sintering process.

Significant Advantages of SPS Technology

Choosing Spark Plasma Sintering technology offers a multitude of benefits for material processing:

- Rapid Sintering: Exceptionally fast heating rates drastically reduce overall sintering time compared to conventional methods.

- Compact Structure: Efficient design minimizes laboratory footprint.

- Uniform Heating: Ensures consistent sintering results throughout the sample.

- High Heating Rate: Enables rapid temperature increases, shortening processing cycles.

- Low Sintering Temperature: Operates at lower temperatures than traditional methods, preserving material integrity and fine microstructures.

- Surface Purification: Plasma discharge purifies particle surfaces, removing impurities and enhancing inter-particle bonding.

- Grain Growth Inhibition: Minimizes undesirable grain growth, resulting in a uniform and controllable product structure.

- Versatile Material Compatibility: Capable of sintering a wide range of materials, including metals, alloys, ceramics, composites, and novel materials.

- Environmental Sustainability: Reduces energy consumption and waste generation compared to conventional methods.

- Cost-Effectiveness: Offers a cost-efficient solution for high-speed sintering by reducing production time and energy expenses.

- Solid-State Diffusion Bonding: Facilitates strong, airtight solid-state diffusion bonding between similar or dissimilar materials.

- Advanced Material Synthesis: Ideal for synthesizing cutting-edge materials such as nanomaterials, functionally graded materials (FGMs), and high-performance rare earth magnets.

Diverse Applications of Spark Plasma Sintering

The Spark Plasma Sintering Furnace (SPS) is a versatile and advanced tool utilized in numerous scientific and industrial applications. Its ability to sinter materials at high speeds and achieve excellent compactness makes it ideal for a range of specialized materials and processes:

- Sintering of Nanophase Materials: Consolidation of nanoscale materials, enhancing their mechanical and physical properties.

- Functionally Graded Materials (FGM): Creation of materials with spatially varying compositions and properties for advanced engineering applications.

- Nanoscale Thermoelectric Materials: Production of high-efficiency materials for energy conversion devices.

- Rare Earth Permanent Magnets: Manufacturing of high-performance magnets used in electronics, automotive, and renewable energy sectors.

- Target Materials: Production of high-purity materials for thin film deposition in electronics and optics.

- Nonequilibrium Materials: Synthesis of materials with unique phases and microstructures not achievable by traditional equilibrium processes.

- Medical Implants: Development of biocompatible materials with precise mechanical properties for advanced medical devices.

- Joining and Forming: Beyond sintering, SPS is effective for joining dissimilar materials and forming complex shapes.

- Surface Modification: Altering surface properties of materials to enhance durability, wear resistance, or functionality.

- Solid Electrolyte and Electric Thermal Material Research: Ideal for the study and production of materials used in solid-state batteries, fuel cells, and thermal management systems.

Technical Specifications & Parameters

Our Spark Plasma Sintering Furnace (SPS) systems, capable of up to 20 Ton pressure and temperatures up to 1600°C (customizable to higher temperatures), are designed for a wide range of material research. They can be used for sintering, sinter-bonding, surface treatment, and synthesis of metals, ceramics, nanostructured materials, and amorphous materials. These systems are perfectly suited for research in solid electrolytes and electrothermal materials.

General Configuration & Features:

| Configuration |

|

| Temperature controller |

|

| Hydraulic Press |

|

| Vacuum Chamber |

|

| Dimension (Typical for a standard model) |

|

Model-Specific Technical Specifications:

| Model | KTSP-10T-5 | KTSP-20T-6 | KTSP-20T-10 | KTSP-50T-30 |

| Rated power | 50Kw | 60Kw | 100Kw | 300Kw |

| Output current | 0-5000A | 0-6000A | 0-10000A | 0-30000A |

| Input voltage (Control Signal) | 0-10V | 0-10V | 0-10V | 0-10V |

| Rated temperature | Standard up to 1600°C (Customizable up to 2300℃ or higher based on requirements) | |||

| Rated pressure | 100KN (10 Ton) | 200KN (20 Ton) | 200KN (20 Ton) | 500KN (50 Ton) |

| Sample size (Max. Die Diameter) | Ø30mm | Ø50mm | Ø100mm | Ø200mm |

| Ram stroke | 100mm | 100mm | 100mm | 200mm |

| Ultimate vacuum | Standard 1Pa (Higher vacuum levels achievable with upgraded pump systems) | |||

Note: Specifications are subject to customization based on specific research and application needs.

Partner with KINTEK for Your Advanced Material Processing Needs

At KINTEK, we understand that unique research demands tailored solutions. Our core strength lies in deep customization. Whether your experiments require specific temperature ranges, higher pressure capacities, larger sample sizes, advanced atmospheric controls, or integrated analytical capabilities, our dedicated R&D and in-house manufacturing teams are equipped to design and build an SPS furnace that precisely meets your unique requirements.

Ready to revolutionize your material synthesis and processing? Don't let standard equipment limit your innovation.

Let's discuss your specific challenges and how our customizable Spark Plasma Sintering furnace solutions can accelerate your research and development. Click the link above or navigate to our contact section to send us your inquiry through the form with ID #ContactForm.

Trusted by Industry Leaders

FAQ

What Is A Dental Furnace Used For?

What Are The Key Features Of A Dental Furnace?

How Does A Dental Furnace Work?

What Are The Advantages Of Using A Dental Furnace?

What Safety Features Should A Dental Furnace Have?

What Types Of Dental Furnaces Are Available?

4.8 / 5

Incredible speed and precision! The SPS Furnace exceeded all expectations. A game-changer for our lab.

4.7 / 5

Top-notch quality and durability. This furnace is built to last and delivers consistent results every time.

4.9 / 5

Worth every penny! The technological advancement in this SPS Furnace is unmatched. Highly recommend!

4.8 / 5

Fast delivery and easy setup. The SPS Furnace has revolutionized our research process. Impressive!

4.9 / 5

The SPS Furnace is a masterpiece of engineering. Perfect for high-performance sintering. Love it!

4.7 / 5

Exceptional value for money. The SPS Furnace delivers precision and efficiency like no other.

4.8 / 5

Cutting-edge technology at its finest. The SPS Furnace has elevated our work to new heights.

4.9 / 5

Reliable and robust. The SPS Furnace is a must-have for any serious research facility.

4.7 / 5

Outstanding performance and durability. The SPS Furnace is a solid investment for any lab.

4.9 / 5

Simply brilliant! The SPS Furnace combines speed, quality, and innovation perfectly.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

Precision Vacuum Press Furnace for labs: ±1°C accuracy, 1200°C max, customizable solutions. Boost research efficiency today!

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

1700℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-17A Controlled Atmosphere Furnace: Precise 1700°C heating with vacuum & gas control. Ideal for sintering, research & material processing. Explore now!

Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

Discover KINTEK's Hydrogen Atmosphere Furnace for precise sintering & annealing in controlled environments. Up to 1600°C, safety features, customizable.

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!

Vacuum Induction Melting Furnace

Explore KINTEK's Vacuum Induction Melting Furnace for high-purity metal processing up to 2000℃. Customizable solutions for aerospace, alloys, and more. Contact us today!

1200℃ Controlled Inert Nitrogen Atmosphere Furnace

KINTEK 1200℃ Controlled Atmosphere Furnace: Precision heating with gas control for labs. Ideal for sintering, annealing, and material research. Customizable sizes available.

1400℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-14A Controlled Atmosphere Furnace for labs & industry. 1400°C max temp, vacuum sealing, inert gas control. Customizable solutions available.

Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

KINTEK Mesh Belt Furnace: High-performance controlled atmosphere furnace for sintering, hardening & heat treatment. Customizable, energy-efficient, precise temperature control. Get a quote now!

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

Laboratory Muffle Oven Furnace with Bottom Lifting

Boost lab efficiency with KT-BL Bottom Lifting Furnace: precise 1600℃ control, superior uniformity, and enhanced productivity for material science and R&D.

1800℃ High Temperature Muffle Oven Furnace for Laboratory

KINTEK Muffle Furnaces: Precision 1800°C heating for labs. Energy-efficient, customizable, with PID control. Ideal for sintering, annealing, and research.

1200℃ Muffle Oven Furnace for Laboratory

KINTEK KT-12M Muffle Furnace: Precision 1200°C heating with PID control. Ideal for labs needing rapid, uniform heat. Explore models & customization options.

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

1400℃ Muffle Oven Furnace for Laboratory

KT-14M Muffle Furnace: Precision 1400°C heating with SiC elements, PID control, and energy-efficient design. Ideal for labs.

2200 ℃ Graphite Vacuum Heat Treat Furnace

2200℃ Graphite Vacuum Furnace for high-temperature sintering. Precise PID control, 6*10⁻³Pa vacuum, durable graphite heating. Ideal for research & production.

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

KINTEK RF PECVD System: Precision thin-film deposition for semiconductors, optics & MEMS. Automated, low-temperature process with superior film quality. Custom solutions available.

Related Articles

Why Your Vacuum Furnace Failed After the Lab Move—And How to Prevent It

Discover why vacuum furnaces often fail after being moved and how robust engineering prevents costly damage to seals and components. Protect your investment.

Why Your Sintered Parts Fail: It’s Not Just About Heat, But Pressure and Purity

Struggling with porous, weak, or contaminated sintered materials? Discover why simply raising the temperature isn't the answer and how the interplay of heat, pressure, and vacuum is the key.

Beyond Mere Heat: The Synthesis Power of Pressure in a Vacuum Furnace

Discover why adding mechanical pressure to a vacuum furnace transforms it from a simple heater into an advanced material synthesis tool for creating dense materials.

How to Select the Right Vacuum Hot Pressing Furnace Temperature for Your Materials

Learn how to choose the right vacuum hot pressing furnace temperature for materials like ceramics, metals, and alloys. Optimize sintering with expert tips.

The Microwave Sintering Trap: Why the 'Best' Furnace Might Be the Wrong Choice for Your Lab

Is microwave sintering always the best choice? Discover the hidden costs and learn a smarter way to select the right high-temperature furnace for your lab.

Mastering Material Purity: The Strategic Role of the Horizontal Vacuum Furnace

Explore how horizontal vacuum furnaces create pristine environments to enhance material properties in heat treatment, sintering, and advanced synthesis.

How Vacuum Hot Press Furnaces Transform Advanced Material Engineering

Vacuum hot press furnaces enable precise material synthesis for aerospace, electronics, and energy sectors, enhancing density, strength, and reliability.

Mastering the Void: How Vacuum Furnaces Forge Strength and Beauty in Dental Restorations

A vacuum furnace actively removes atmospheric gases during firing, eliminating porosity and oxidation for stronger, more aesthetic dental restorations.

Cracked Zirconia, Inconsistent Shades: The Real Reason Your Sintering Furnace Is Failing You

Stop blaming materials. Discover the root cause of inconsistent dental sintering—the 'one-size-fits-all' furnace—and how a purpose-built solution ends costly remakes.

Beyond the Parts List: The Real Reason Your Vacuum Hot Press Fails (And How to Fix It)

Frustrated with inconsistent vacuum hot press results? Discover why just upgrading parts fails and how a system-based approach unlocks repeatable success.

How CVD Diamond Synthesis Methods Compare for Industrial Applications

Compare CVD diamond synthesis methods (HFCVD, DC Plasma Arc Jet, MPCVD) for cost, quality, and industrial applications like tools, optics, and quantum tech.