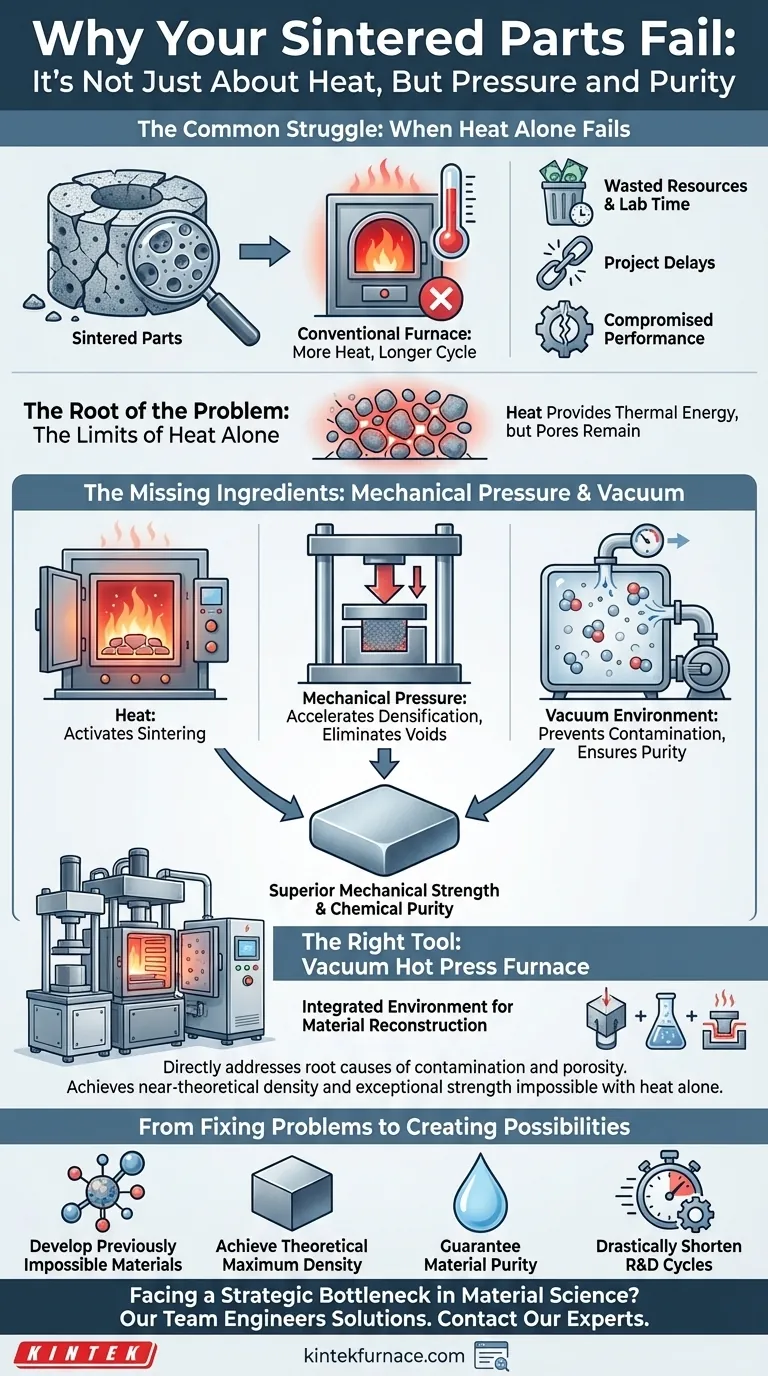

Does this scenario sound familiar? You’ve spent weeks perfecting a new material formula, meticulously preparing your sample, and running it through a long, high-temperature sintering cycle. You retrieve the finished part, but under analysis, it’s a failure. It’s brittle, riddled with microscopic pores, or has been contaminated by a chemical reaction, completely compromising its properties. You’ve already tried raising the temperature and extending the cycle time, yet the results remain stubbornly inconsistent.

The Common Struggle: When "Trying Harder" with Conventional Furnaces Fails

This cycle of trial-and-error is one of the most significant bottlenecks in advanced materials research and development. In labs around the world, the default response to a failed sintering process is to tweak the most obvious variable: heat. The thinking goes, "If we just heat it hotter, or for longer, the atoms will surely bond more effectively."

While logical, this approach rarely solves the fundamental problem for high-performance materials. These repeated attempts lead to significant negative consequences:

- Wasted Resources: Each failed cycle consumes expensive raw materials, valuable energy, and irreplaceable lab time.

- Project Delays: The inability to produce reliable components pushes timelines back, delaying new product launches and hindering research progress.

- Compromised Performance: Even "partially successful" parts that make it through testing may harbor hidden defects, creating a risk of failure in critical applications like aerospace components, medical implants, or cutting-edge electronics.

The core issue is that these conventional solutions are based on a misunderstanding of the problem. You're trying to solve a three-dimensional problem with a one-dimensional tool.

The Root of the Problem: The Limits of Heat Alone

The reason simply adding more heat fails is that it only addresses one part of the material consolidation process. To create exceptionally dense and pure materials, you must simultaneously control three distinct physical forces: heat, pressure, and the environment.

The Missing Ingredient: Mechanical Pressure

Heat provides the thermal energy to make the atoms within your material mobile, allowing them to start forming bonds—a process known as sintering. However, heat alone does not physically eliminate the empty spaces (pores) between material particles.

Imagine building a wall with bricks that have no mortar. Making the bricks warmer might make them slightly soft, but it won’t force them together to create a solid, seamless structure. That’s the job of mechanical pressure. By applying immense force, a hot press physically squeezes out the voids, compacting the material and accelerating densification to a level that heat alone could never achieve. This is the key to superior mechanical strength.

The Unseen Enemy: Atmospheric Contamination

Even in a furnace filled with an "inert" gas, trace amounts of reactive gases like oxygen are almost always present. At high temperatures, these gases will aggressively react with many advanced materials, causing oxidation and contamination that severely degrades their electrical, mechanical, and chemical properties.

This is where a vacuum becomes non-negotiable. By pumping out the atmosphere, you remove these reactive elements, creating a pristine environment. This shield is the only way to ensure the absolute chemical purity required for reactive metals, advanced ceramics, and sensitive composites.

Conventional furnaces fail because they can't effectively apply pressure or create a true vacuum. They are fighting a losing battle against porosity and contamination from the start.

The Right Tool for a Fundamental Problem

To truly solve this, you don't need a slightly better oven; you need a system designed from the ground up to master all three critical elements. This is the purpose of a Vacuum Hot Press Furnace.

It is not just another piece of heating equipment; it is an integrated environment engineered to fundamentally reconstruct materials.

- Its powerful vacuum system directly addresses the root cause of contamination, creating the ultra-pure environment needed to process reactive and sensitive materials.

- Its high-force pressing mechanism directly solves the problem of porosity, achieving near-theoretical density and exceptional strength that is physically impossible with heat alone.

- Its advanced heating elements provide the precise thermal control needed to activate the sintering process for even the most difficult-to-sinter refractory metals and ceramics.

At KINTEK, we understand that every material presents a unique challenge. A one-size-fits-all approach is insufficient. Our deep customization capability allows us to design a vacuum hot press system with the specific temperature, pressure, and vacuum profiles your unique application demands, ensuring your equipment is a solution, not just a tool.

From Fixing Problems to Creating Possibilities

When you are no longer constrained by the limitations of conventional sintering, the focus of your work shifts from troubleshooting to true innovation. Having precise, simultaneous control over heat, pressure, and vacuum unlocks new frontiers in material science.

You can now:

- Develop materials that were previously impossible to consolidate, like novel metal-ceramic composites.

- Achieve theoretical maximum density, enabling the creation of components that can withstand the most extreme mechanical stresses.

- Guarantee material purity, a critical factor for next-generation semiconductors and biocompatible implants.

- Drastically shorten R&D cycles by eliminating the guesswork and producing reliable, repeatable results from the first attempt.

Ultimately, solving this foundational processing problem frees your most valuable resource—your team's expertise—to focus on discovery and pushing the boundaries of what is possible.

The gap between a promising material on paper and a high-performance component in reality is defined by the processing environment. If your projects are stalled by inconsistent density, contamination, or the inherent limitations of your current heating methods, you are not just facing a technical hurdle—you are facing a strategic bottleneck. Our team doesn't just sell furnaces; we engineer solutions to complex material science challenges. Let's discuss the specific requirements of your next groundbreaking project and design the precise environment you need to succeed. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

Related Articles

- Why Your High-Purity Metals Oxidize in a Perfect Vacuum—And How to Stop It

- The Real Reason Your High-Performance Materials Are Failing (And It’s Not the Alloy)

- Why Your High-Temperature Materials Fail: The Hidden War Inside Your Furnace

- How Vacuum Hot Press Furnaces Transform Advanced Material Engineering

- How Vacuum Pressure Sintering Furnaces Elevate Material Performance Across Industries