You’ve done everything right. The parameters were triple-checked, the sample materials were pristine, and the vacuum furnace ran its cycle flawlessly, holding the precise temperature for the required duration. Yet, when you open the chamber, the result is a disaster. The advanced alloy is brittle, the single crystal is contaminated, the ceramic component is discolored. Weeks of work and expensive materials are lost, and the most frustrating part is that you don't know why. The machine did its job perfectly. Or did it?

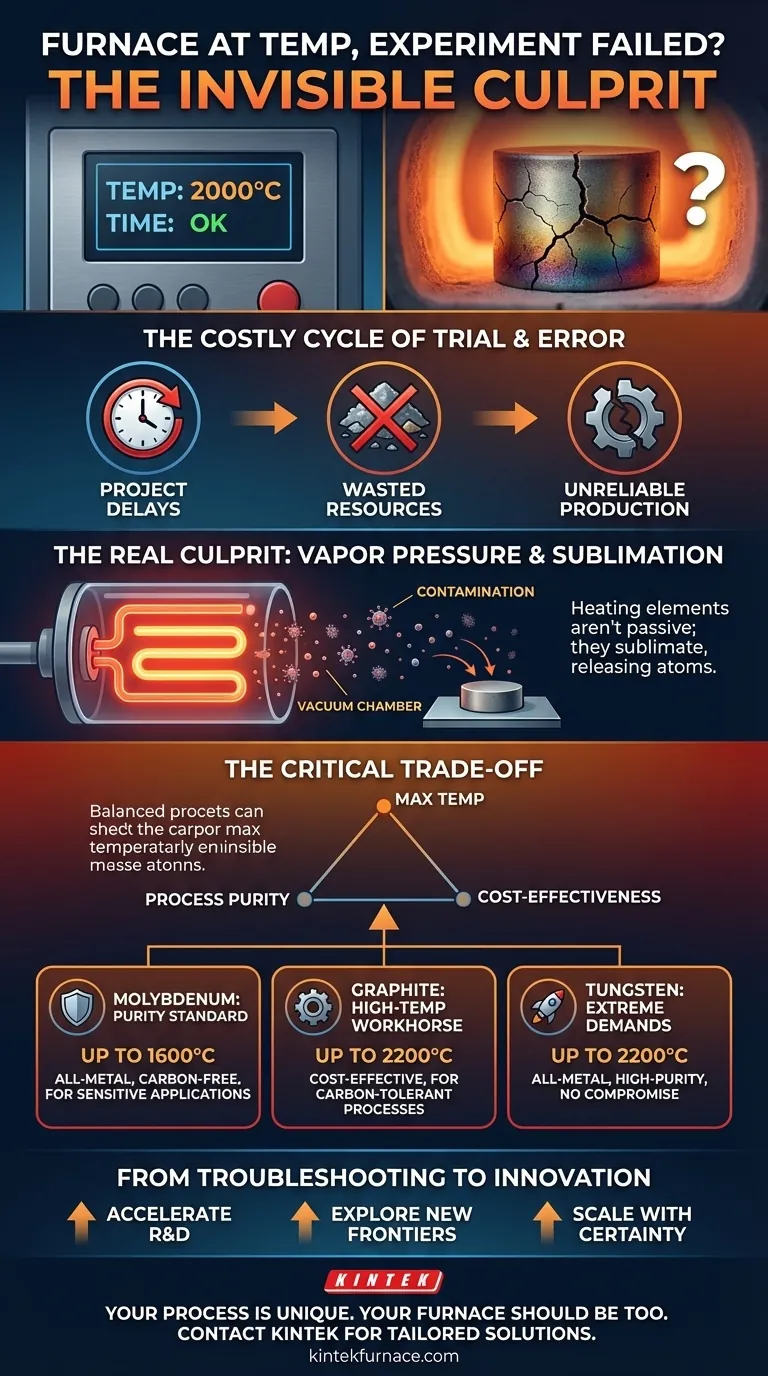

The Costly Cycle of Trial and Error

This scenario is far too common in advanced R&D labs and high-value manufacturing. A team encounters an unexplainable process failure and begins a frustrating cycle of troubleshooting. They might blame the raw materials, adjust process times, or run countless cleaning cycles on the vacuum chamber. Each attempt eats into budgets and timelines, eroding confidence in the process.

The business consequences are severe and tangible:

- Project Delays: Critical R&D milestones are pushed back, delaying time-to-market for new products.

- Wasted Resources: Batches of expensive, custom-synthesized materials are rendered useless.

- Unreliable Production: In a manufacturing setting, this can lead to low yields, scrapped parts, and a damaged reputation for quality.

These efforts are often doomed from the start because they focus on the symptoms. The real problem is silent, invisible, and fundamental to the furnace's design: the heating element itself.

The Real Culprit: A Ghost in the Machine

The assumption that a heating element's only job is to get hot is a dangerous oversimplification. In the extreme environment of a high-temperature vacuum, the heating element is not a passive component; it is an active participant in your process chemistry.

It's Not Just Hot, It's an Active Environment

The core of the issue lies in a basic physical principle: vapor pressure. At high temperatures and in a vacuum, all materials—even solids—have a tendency to sublimate, releasing atoms directly into the environment. A heating element glowing at 2000°C is actively shedding microscopic particles.

This is the hidden source of contamination. If your process is sensitive to carbon, but your furnace uses a graphite heating element, you are essentially running your experiment inside a microscopic carbon storm. No amount of process tweaking can fix this fundamental incompatibility. The "common solutions" fail because they don't address the fact that the furnace itself is poisoning the experiment.

The Critical Trade-Off: Temperature, Purity, and Cost

Choosing a heating element isn't about finding one that can simply withstand the heat. It's a calculated decision based on a critical trade-off between three factors:

- Maximum Temperature: Can it reach the required process temperature reliably?

- Process Purity: Will the element itself introduce contaminants that compromise the sample?

- Cost-Effectiveness: What is the long-term operational cost, including element lifetime and potential for sample loss?

The material you choose dictates the balance. Graphite is a cost-effective workhorse for temperatures up to 2200°C, but it is a source of carbon. Refractory metals like molybdenum and tungsten offer exceptionally clean environments but come with different temperature ranges and cost considerations.

Choosing the Right Tool, Not Just a Hotter Box

To permanently solve these "ghost" failures, you need more than a furnace that meets a temperature spec. You need a thermal processing system designed with a deep understanding of your material science. The heating element must be selected as a strategic component of your process, not an afterthought.

This is where a furnace isn't just a commodity, but a tailored solution. At KINTEK, our approach is built on this principle. Our deep customization capability, backed by in-house R&D and manufacturing, allows us to design a furnace around your specific process chemistry.

The Molybdenum Standard for Purity

For processes where purity is non-negotiable—such as medical implants, semiconductor materials, or aerospace alloys—an "all-metal" hot zone is the gold standard. Our furnaces configured with molybdenum heating elements provide an impeccably clean, carbon-free environment for stable processing up to 1600°C. This directly eliminates the risk of carbon contamination that plagues so many sensitive applications.

Graphite: The High-Temperature Workhorse

When your process can tolerate a carbon environment or requires cost-effective processing at very high temperatures (up to 2200°C), our systems with high-purity graphite elements offer unparalleled performance and value. The key is knowing when it's the right choice for the chemistry involved.

Tungsten for the Most Extreme Demands

For the most demanding applications that require both extreme temperatures (up to 2200°C) and an all-metal, high-purity environment, tungsten is the necessary choice. We engineer these systems for cutting-edge research and production where no compromise is acceptable.

From Troubleshooting to True Innovation

When your furnace is no longer a source of uncertainty, a fundamental shift occurs. The time, money, and intellectual energy once spent on diagnosing mysterious failures are now liberated and can be redirected toward your core mission.

Imagine being able to:

- Accelerate R&D: Trust your experimental results and move forward with confidence, drastically shortening development cycles.

- Explore New Frontiers: Work with novel, highly sensitive materials that were previously impossible to process without contamination.

- Scale with Certainty: Transition from laboratory success to reliable, high-yield production, knowing your thermal process is robust and repeatable.

Solving the heating element puzzle isn't just about fixing a problem; it's about unlocking the full potential of your research and manufacturing capabilities.

Your process is unique. Your furnace should be too. Instead of wrestling with a system that works against your chemistry, let our team help you specify a solution that guarantees the performance and purity your project demands. Contact Our Experts to discuss your application and build a furnace that truly enables your innovation.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

Related Articles

- The Physics of Perfection: How Vacuum Furnaces Redefine Material Integrity

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

- Beyond the Void: A Framework for Choosing Your Vacuum Furnace

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation