The Invisible Enemy in Every Room

For most of human history, the air we breathe has been an accepted, invisible constant. It's the backdrop to everything we do.

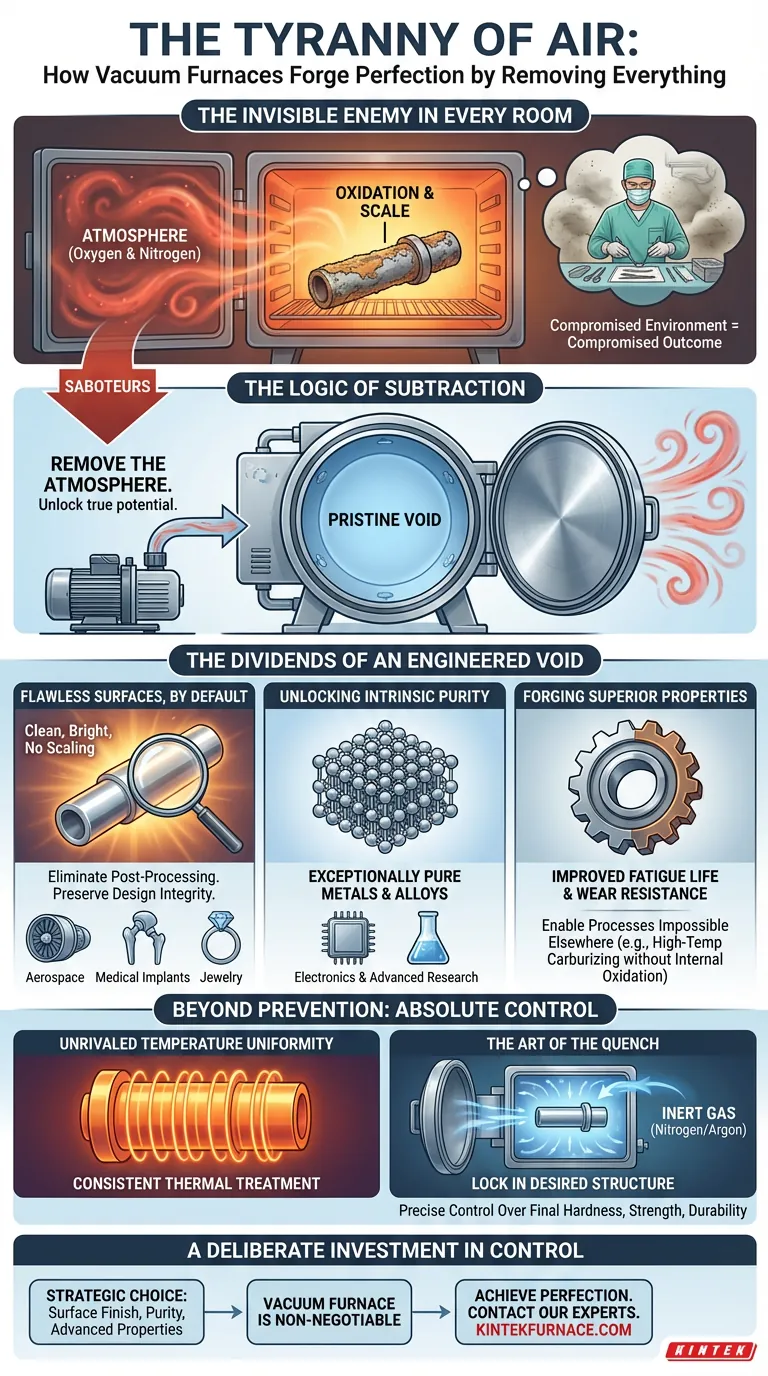

But in the world of material science and high-temperature metallurgy, this seemingly harmless atmosphere becomes a saboteur. At elevated temperatures, the oxygen and nitrogen that surround us turn into aggressive contaminants. They attack heated metals in a process called oxidation, creating a brittle, discolored layer of scale. This isn't just a cosmetic issue; it's a fundamental degradation of the material's integrity.

Imagine a surgeon trying to operate in a dusty room. No matter how skilled their hands or sharp their tools, the outcome is compromised by an environment filled with contaminants. A conventional furnace faces the same challenge. It heats the material, but it does so in a "dirty" atmospheric room, inviting unwanted chemical reactions that alter the final product.

The Logic of Subtraction

The most elegant solution to this problem is not to add a protective layer or a chemical inhibitor. The solution is subtraction.

A vacuum furnace operates on a simple, profound principle: if the atmosphere is the problem, remove the atmosphere.

By pumping the air out of a sealed chamber, the furnace creates a low-pressure, near-empty environment. It transforms the chamber from a simple heater into a highly controlled stage where materials can be treated without interference. This isn't just about preventing rust; it's about creating a pristine void where the true potential of a material can be unlocked.

The Dividends of an Engineered Void

Once the invisible enemy is removed, the benefits are immediate and profound.

Flawless Surfaces, By Default

The most obvious result is a clean, bright part, straight from the furnace. With no oxygen to cause scaling, components retain their original metallic luster.

This is non-negotiable in industries where surface finish is paramount:

- Aerospace: Where surface imperfections can impact aerodynamic performance and fatigue life.

- Medical Implants: Where a pure, unblemished surface is critical for biocompatibility.

- Jewelry: Where appearance is the primary measure of value.

Eliminating post-processing steps like chemical cleaning or sandblasting doesn't just save time; it preserves the integrity of the part's design.

Unlocking Intrinsic Purity

Beyond the surface, a vacuum prevents atmospheric gases from dissolving into the material itself. This allows for the creation of exceptionally pure metals and alloys, a necessity for the demanding world of electronics and advanced research. You get the material you designed, not an accidental alloy contaminated by the air in the room.

Forging Superior Properties

A vacuum environment enables metallurgical processes that are impossible in a conventional furnace. High-temperature carburizing, for instance, becomes faster and more effective.

Crucially, without oxygen, there is no "internal oxidation" within the carburized layer. The result is a dramatic improvement in fatigue life and wear resistance—properties forged in an environment of absolute purity.

Beyond Prevention: The Realm of Absolute Control

A vacuum furnace is more than just a tool for prevention. It is an instrument of precision, offering a level of control that atmospheric furnaces cannot match.

Unrivaled Temperature Uniformity

Engineered for thermal management, vacuum furnaces provide exceptionally uniform heat. Advanced insulation and control systems ensure every part of a component—thick or thin, simple or complex—receives the exact same thermal treatment. This precision is the foundation of consistency.

The Art of the Quench

Control over the heating cycle is only half the story. Many vacuum furnaces allow for rapid cooling by backfilling the chamber with a high-purity inert gas like nitrogen or argon. This "quenching" process locks in the desired metallurgical structure created during heating, giving engineers precise control over the final hardness, strength, and durability.

The Promise of Repeatability

Because the entire process—from pumping down to a specific vacuum level to executing a precise heating and quenching recipe—is managed by computer control, the results are highly repeatable. Every part in a batch, and every batch over time, achieves identical properties. For industrial manufacturing, this is the guarantee of quality at scale.

A Deliberate Investment in Control

This level of precision comes with trade-offs. Vacuum furnaces represent a higher initial investment and require more complex maintenance. The pump-down cycle adds time. They are not a universal fix for every heat-treating task.

The choice to use a vacuum furnace is a strategic one, based on your ultimate goal:

- If your priority is surface finish and purity, a vacuum is non-negotiable.

- If you need to achieve specific, advanced metallurgical properties, a vacuum provides the necessary control.

- If your focus is high-volume processing where minor oxidation is acceptable, a conventional furnace may be more practical.

Ultimately, a vacuum is a tool for control. It empowers engineers to move from hoping for a good outcome to engineering it with certainty.

For laboratories and industries pushing the boundaries of material science, this control is not a luxury; it's a necessity. Achieving superior purity, enhanced properties, and unmatched consistency requires an environment tailored to perfection. With deeply customizable solutions ranging from high-temperature vacuum furnaces to advanced CVD systems, KINTEK provides the precise instruments needed to master that environment. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

Related Articles

- The Three-Axis Logic: How to Choose a Vacuum Furnace That Works

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- Gravity as an Ally: The Counterintuitive Genius of Vertical Vacuum Furnaces