The Hidden Enemy in High-Temperature Metallurgy

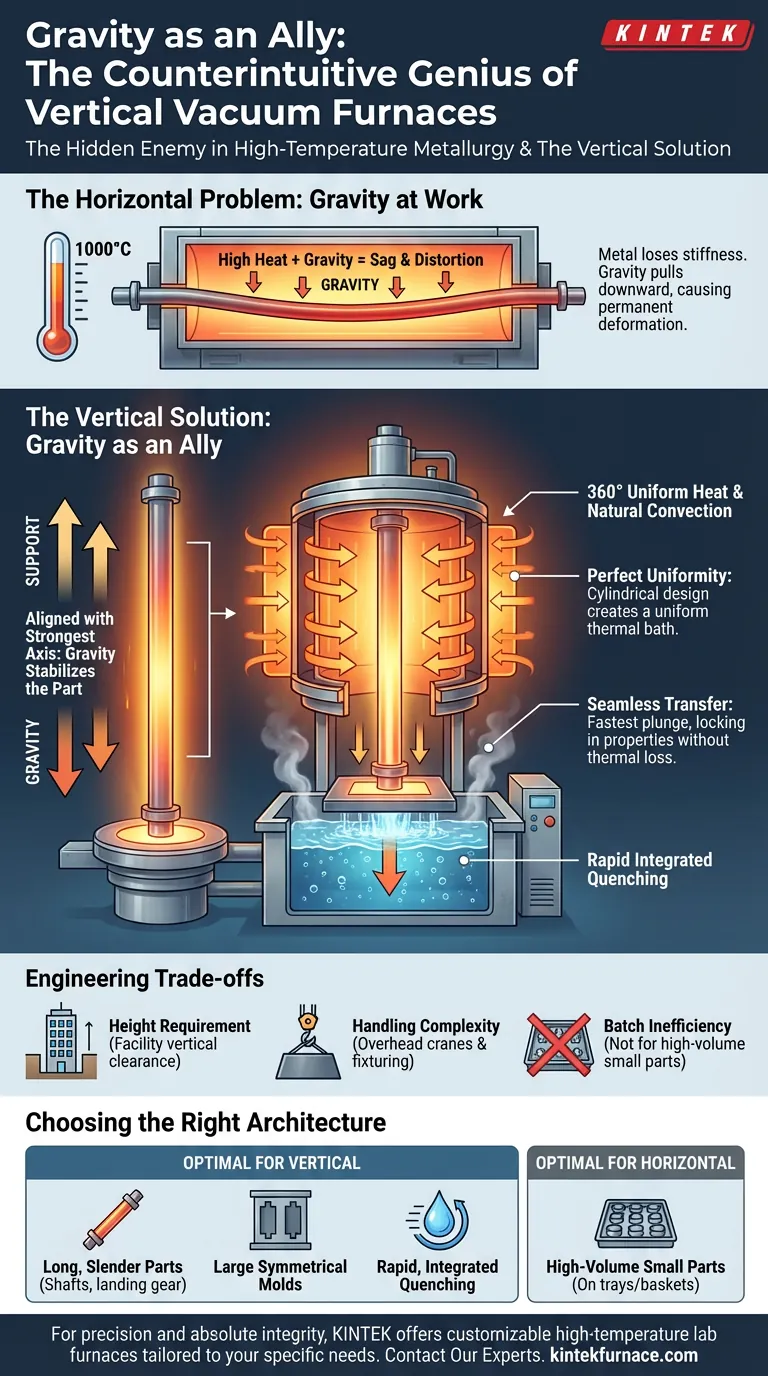

At room temperature, a precision-machined steel driveshaft is a testament to rigidity and strength. At 1000°C, it's a different story. Metal loses its stiffness, becoming vulnerable to its own weight. In a conventional horizontal furnace, gravity becomes a relentless enemy, pulling the component downward, causing sag, bow, and distortion that can render a priceless part worthless.

This is the silent battle fought in every heat treatment cycle: a struggle against physics itself. How do you subject a component to extreme, uniform heat without letting it deform under its own mass?

The answer is counterintuitive. You don't fight gravity; you make it your ally.

Flipping the Problem on Its Head

A vertical vacuum furnace is not just a different orientation; it's a different philosophy. Instead of laying a long part down to be attacked by gravity from the side, it stands the part up, aligning its strongest axis with the force of gravity.

The mechanism is elegant in its simplicity:

- The load, such as a long shaft or a large mold, is placed on a robust hearth at floor level.

- A powerful lift system raises the entire hearth assembly vertically, carrying the component up into the stationary, cylindrical heating chamber above.

- Once in position, the hearth seals against the chamber, creating the airtight environment needed for a vacuum.

The component is supported from its base, just like a skyscraper. Gravity now serves to stabilize the part, not distort it. This fundamental shift in architecture is what makes the vertical furnace a specialized master of specific, high-stakes applications.

Beyond Stability: The Unseen Advantages

Solving the distortion problem is the primary victory, but the vertical design unlocks other critical benefits that are impossible to achieve in a horizontal layout.

The Pursuit of Perfect Uniformity

In a large horizontal furnace, ensuring every part of a load receives the exact same temperature is a constant challenge. "Cold spots" can lead to inconsistent metallurgical properties.

The cylindrical chamber of a vertical furnace allows for a 360-degree arrangement of heating elements. This, combined with the natural convection of heat rising, creates an exceptionally uniform thermal environment. For large dies or complex aerospace components, this perfect "bath" of heat isn't a luxury; it's a necessity for achieving reliable, repeatable results.

The Critical Moment of Quenching

The transition from heating to quenching is a race against time. The goal is to "lock in" the desired crystalline structure by cooling the part at a precise, rapid rate. Any delay causes a loss of heat and a less effective quench.

Many vertical furnaces are designed with an integrated quench tank (oil, water, or gas) located directly below the heating chamber. When the cycle is complete, the hearth lowers rapidly, plunging the hot component into the quench medium in a matter of seconds. This seamless transfer is a masterstroke of efficiency, eliminating the thermal loss and variability of moving a part horizontally from one chamber to another.

Engineering Is About Trade-offs

No design is a universal solution. The power of the vertical furnace comes with specific considerations.

- Architectural Demands: The most significant constraint is height. A facility needs substantial vertical clearance or a purpose-built pit to accommodate the furnace and its loading mechanism.

- Handling Complexity: While the furnace does the heavy lifting, positioning a large, awkward component onto the hearth requires overhead cranes and careful fixturing.

- Batch Inefficiency: It is a specialist's tool. For processing high volumes of small, assorted parts that can be stacked on trays, a horizontal furnace often provides greater efficiency and flexibility.

Choosing the Right Architecture for the Job

The decision between a horizontal and vertical furnace is a strategic one, dictated entirely by the part and the process.

| Application Focus | Optimal Furnace Architecture | Why? |

|---|---|---|

| Long, Slender Parts (Shafts, tubes, landing gear) | Vertical | Aligns gravity with the part's strong axis to eliminate distortion and sag. |

| Large, Symmetrical Molds & Dies | Vertical | Provides superior 360° temperature uniformity, critical for consistent properties across the part. |

| Rapid, Integrated Quenching | Vertical | The bottom-loading design allows for the fastest, most direct transfer into an integrated quench. |

| High-Volume, Small Assorted Parts (On trays or baskets) | Horizontal | Offers greater loading flexibility and is generally more efficient for bulk processing. |

For laboratories and R&D settings where precision is paramount, these trade-offs are often easy to justify. The need for absolute dimensional integrity in a prototype or a small batch of critical components demands a specialized approach. This is where customizable systems, like the high-temperature lab furnaces offered by KINTEK, provide a decisive advantage. By tailoring Muffle, Tube, or Vacuum furnaces to the specific geometry and metallurgical needs of a unique project, the right tool is always available.

Understanding this architecture is the first step toward protecting the integrity of your most valuable components. If your work demands this level of precision, Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- The Architecture of Purity: Deconstructing the Vacuum Furnace System

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- Beyond the Void: The Hidden Costs of a Perfect Vacuum Furnace