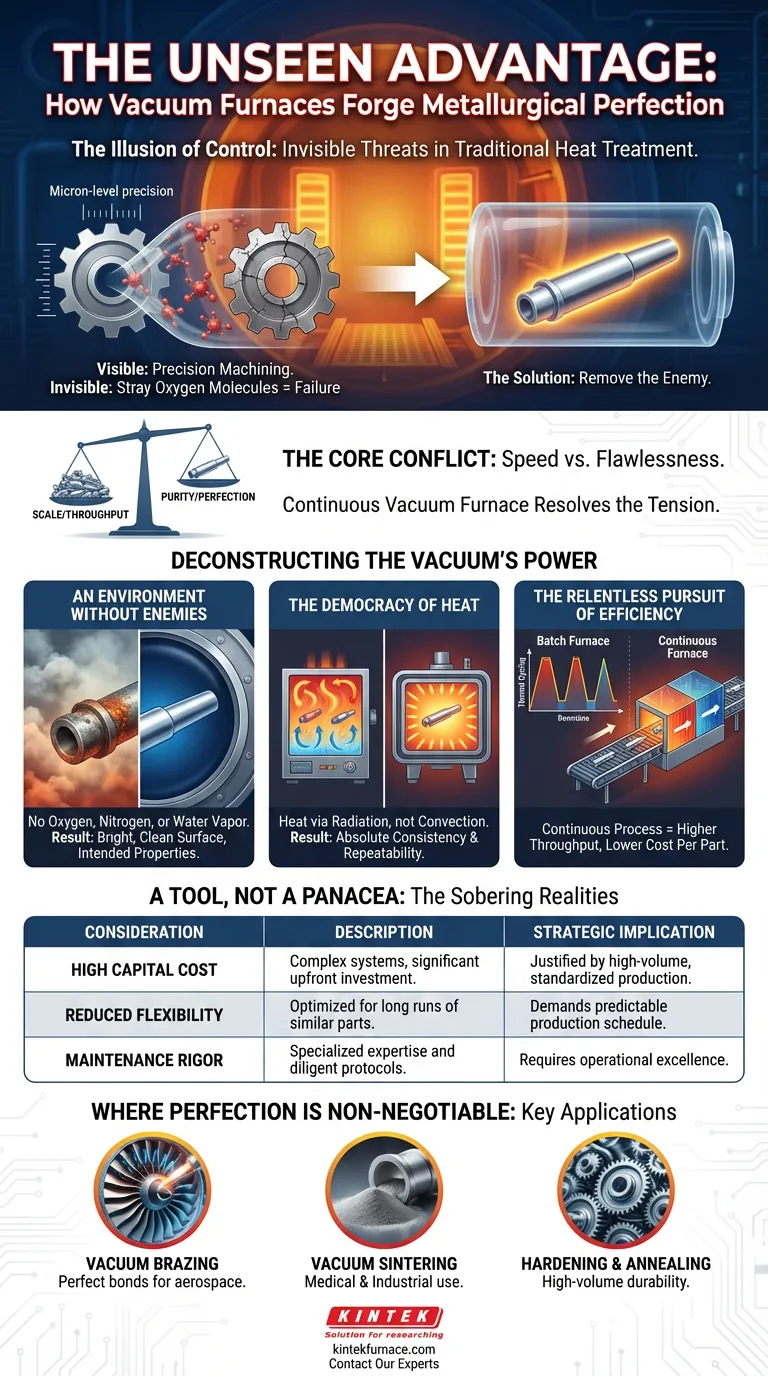

The Illusion of Control

In the world of metallurgy, the greatest threats are often invisible. A team can spend months designing a critical aerospace component, machining it to micron-level precision, only to have it fail because of a few stray oxygen molecules in a furnace.

This is the engineer's paradox: striving for absolute control over a process that is profoundly sensitive to an environment we can't even see. Traditional heat treatment, with its reliance on atmosphere or inert gases, is a constant battle against these unseen contaminants. It’s a process of approximation, not perfection.

But what if you could remove the enemy from the equation entirely?

The Core Conflict: Scale vs. Purity

Modern manufacturing is defined by a fundamental tension. We need to produce components at an immense scale, but we also need them to be flawless. Speed and perfection are often opposing forces. Pushing for higher throughput can compromise the meticulous control needed for superior metallurgical properties.

This is where the continuous vacuum furnace emerges not just as a piece of equipment, but as a paradigm shift. It resolves the conflict by creating an environment where high-volume production and pristine quality can coexist.

It achieves this by mastering two distinct elements: the vacuum for quality and the continuous process for efficiency.

Deconstructing the Vacuum's Power

The magic of a vacuum furnace isn't just in what it does, but in the physics it exploits. By removing the atmosphere, it fundamentally changes the rules of heat treatment.

An Environment Without Enemies

At high temperatures, metal is vulnerable. The oxygen in the air, normally benign, becomes an aggressive agent, forming a brittle oxide layer (scale) that degrades the surface and compromises the part's integrity.

A vacuum creates a sanctuary. By evacuating the chamber, we remove the oxygen, nitrogen, and water vapor. The metal can be heated to extreme temperatures without the threat of these unwanted chemical reactions. The result is a bright, clean surface straight from the furnace, with metallurgical properties exactly as intended.

The Democracy of Heat

In a standard furnace, heat is transferred through convection—the movement of hot air. This process is inherently uneven, creating hot and cold spots that can warp complex parts and lead to inconsistent results.

In a vacuum, heat transfer occurs primarily through radiation. Thermal energy radiates directly and uniformly from the heating elements to the parts. Every surface, every angle, every component in the load receives the same amount of energy. This "democracy of heat" ensures absolute consistency and repeatability, a non-negotiable requirement in fields like medical implants and automotive safety components.

The Relentless Pursuit of Efficiency

A batch furnace is a study in inefficiency. It must be heated, used, cooled, unloaded, reloaded, and reheated. The furnace itself endures constant thermal cycling, wasting enormous amounts of energy and time.

A continuous furnace, however, operates with a relentless rhythm. Parts move steadily through dedicated heating and cooling zones without interruption. This eliminates the thermal cycling of the furnace structure, dramatically increasing throughput and lowering the cost per part. It's a system designed for the logic of the modern assembly line.

A Tool, Not a Panacea: The Sobering Realities

For all its power, the continuous vacuum furnace is a specialized instrument. Its strengths are balanced by specific limitations that an engineering team must respect.

| Consideration | Description | Strategic Implication |

|---|---|---|

| High Capital Cost | These are complex, large-scale systems requiring a significant upfront investment. | Justified only by high-volume, standardized production where efficiency gains are paramount. |

| Reduced Flexibility | Optimized for long runs of similar parts. Not efficient for small, diverse batches with varied cycles. | Demands a predictable and stable production schedule to realize its full potential. |

| Maintenance Rigor | Complex vacuum and automation systems require specialized expertise and diligent maintenance protocols. | Requires a commitment to operational excellence and skilled technical staff. |

Where Perfection is Non-Negotiable

The applications for this technology are found where the cost of failure is astronomical.

- Vacuum Brazing: In aerospace, joining complex turbine blades requires a perfectly clean surface for the brazing alloy to form a bond stronger than the parent metals. A vacuum provides the only environment pure enough to guarantee this.

- Vacuum Sintering: Turning compacted metal powder into a dense, solid part for medical or industrial use demands an oxygen-free environment to prevent the fine particles from oxidizing, ensuring maximum strength and purity.

- Hardening & Annealing: For automotive gears or bearings produced by the million, continuous vacuum hardening ensures every single part meets the exact same specifications for durability and performance.

Choosing Your Instrument: A Matter of Intent

The decision to use a continuous vacuum furnace—or any furnace—is a reflection of your operational philosophy. Are you focused on high-volume consistency, or agile, small-batch precision?

This is where having a knowledgeable partner becomes critical. The ideal solution might be a robust continuous vacuum system, a flexible batch vacuum furnace, or even a highly specialized CVD system for cutting-edge materials research.

Understanding this landscape is the first step. At KINTEK, our expertise across a wide range of high-temperature systems—from versatile Tube and Muffle furnaces to highly specific, customizable Vacuum and CVD platforms—is built on this principle. We don't just provide equipment; we engineer solutions tailored to your unique goals. If you're ready to achieve a new level of material quality and production efficiency, Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

Related Articles

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

- The Physics of Perfection: How a Vacuum Furnace Creates Order from Chaos

- The Unseen Enemy: Why Vacuum Furnaces Are a Bet on Perfection

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection