The Invisible Saboteur in a Red-Hot Room

Imagine a team of metallurgists perfecting a new alloy for a mission-critical aerospace component. The chemistry is flawless, the design elegant. But during the final heat treatment, an invisible enemy attacks: the very air in the furnace.

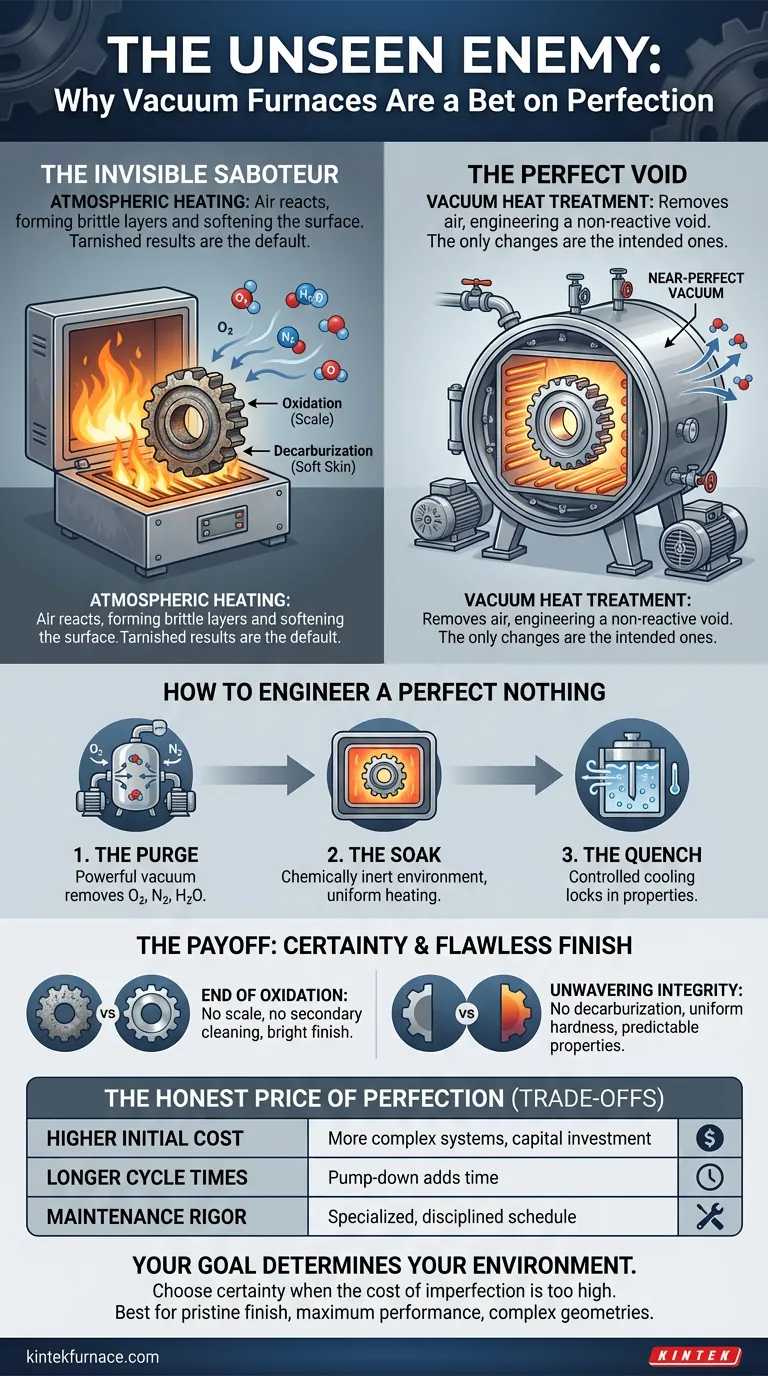

At extreme temperatures, the oxygen we breathe becomes a saboteur. It reacts with the metal's surface, forming a brittle, scaly layer (oxidation). It leaches carbon from the steel, softening its skin and compromising its wear resistance (decarburization).

The team’s brilliant work is tarnished at the last step. This isn't a rare failure; it's the default outcome when you heat metal in the open. The traditional response has been to mitigate the damage. The modern answer is to eliminate the enemy entirely.

The Psychology of Subtraction

Our instinct is often to solve problems by adding something—a protective gas, a chemical wash, a post-treatment grinding process. Vacuum heat treatment operates on a more profound, counter-intuitive principle: the most powerful addition is subtraction.

By placing a part in a sealed chamber and removing the air, you are not just heating metal. You are engineering a perfect, non-reactive void. You are creating an environment where the only changes that occur are the ones you intend.

This is a fundamental shift in mindset. It's a move from fighting an unpredictable atmosphere to creating a predictable, controlled universe on a small scale.

How to Engineer a Perfect Nothing

The mechanics are an elegant display of physics and engineering, built on a simple premise.

- The Purge: A powerful vacuum system extracts the air from a sealed furnace chamber, reducing the internal pressure to a near-perfect vacuum. The saboteurs—oxygen, nitrogen, water vapor—are evicted.

- The Soak: With the environment now chemically inert, heat is applied. This can be through conventional resistance elements or advanced induction methods. The material is heated to a precise temperature and held there, allowing its internal structure to transform uniformly, without surface interference.

- The Quench: Cooling is just as controlled. High-pressure inert gas or specialized liquids can be used to cool the part at a calculated rate, locking in the desired properties like hardness and strength.

Throughout this entire ballet of temperature and pressure, the vacuum holds the line. It ensures the material's surface remains as pristine as its core.

The Payoff: Certainty and a Flawless Finish

Choosing to control the environment isn't an academic exercise. The results are tangible, dramatic, and often cost-effective in the long run.

The End of Oxidation

The most immediate benefit is visual. Parts emerge from a vacuum furnace with a clean, bright, almost polished finish. They look exactly as they did when they went in, only now they possess the required metallurgical properties.

This eliminates the need for costly and damaging secondary operations like sandblasting, acid pickling, or machining to remove scale. The part is finished the moment it cools.

Unwavering Material Integrity

Because there is no atmosphere to react with, the properties of the material are stunningly consistent.

- No Decarburization: The surface of a high-carbon steel part remains as hard as its core.

- Uniform Hardness: Heating is more uniform without air currents, and the controlled quench delivers predictable properties across the entire part, and from one batch to the next.

This level of predictability is the foundation of modern high-performance manufacturing.

The Honest Price of Perfection

Such absolute control does not come without its trade-offs. It requires a different kind of investment in technology and process.

| Trade-Off | The Strategic Consideration |

|---|---|

| Higher Initial Cost | Vacuum furnaces and their pumping systems are more complex than atmospheric ovens, representing a significant capital investment. |

| Longer Cycle Times | The pump-down phase to achieve a deep vacuum adds time to each cycle, a key factor in very high-volume production. |

| Maintenance Rigor | The seals, pumps, and controls that maintain the vacuum demand a disciplined and specialized preventative maintenance schedule. |

Acknowledging these factors isn't a mark against the technology. It's an honest assessment of what it takes to achieve a superior result. It's the choice between "good enough" and "as perfect as possible."

Your Goal Determines Your Environment

The decision to use a vacuum furnace is an investment in certainty. It’s right for you when the cost of imperfection—whether in performance, appearance, or post-processing—is too high to ignore.

- For a pristine surface finish: When aesthetics matter or when secondary cleaning is impractical, the vacuum is the only answer.

- For maximum material performance: For high-stress components, advanced alloys, and medical implants, preventing any surface degradation is non-negotiable.

- For complex geometries: Uniform heating without air currents prevents distortion in intricate parts.

At KINTEK, we specialize in building the tools for those who choose certainty. Our expertise in R&D and manufacturing allows us to engineer high-temperature vacuum furnaces that are not just machines, but complete, customized solutions. We understand the physics of the void and the practical demands of the lab and factory floor.

If you are ready to eliminate the unseen enemy and unlock the full potential of your materials, let's build the perfect environment together. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

- The Real Reason Your High-Performance Materials Are Failing (And It’s Not the Alloy)

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation