The Invisible Enemy in the Chamber

A metallurgist pulls a batch of aerospace components from a vacuum furnace. The heating cycle was perfect, the data logs are clean, but the parts are ruined. A faint, tell-tale discoloration on the surface signals oxidation—the very contamination the furnace was designed to prevent.

The error wasn't in the heat. It was in the emptiness. A microscopic leak in a door seal, imperceptible to the eye, allowed a few stray molecules of oxygen to become a catastrophic contaminant at 1200°C.

This scenario reveals a fundamental truth: a vacuum furnace is not simply an oven. It is a sophisticated environmental control system. Its mastery is less about managing heat and more about a disciplined, almost psychological, battle against the invisible.

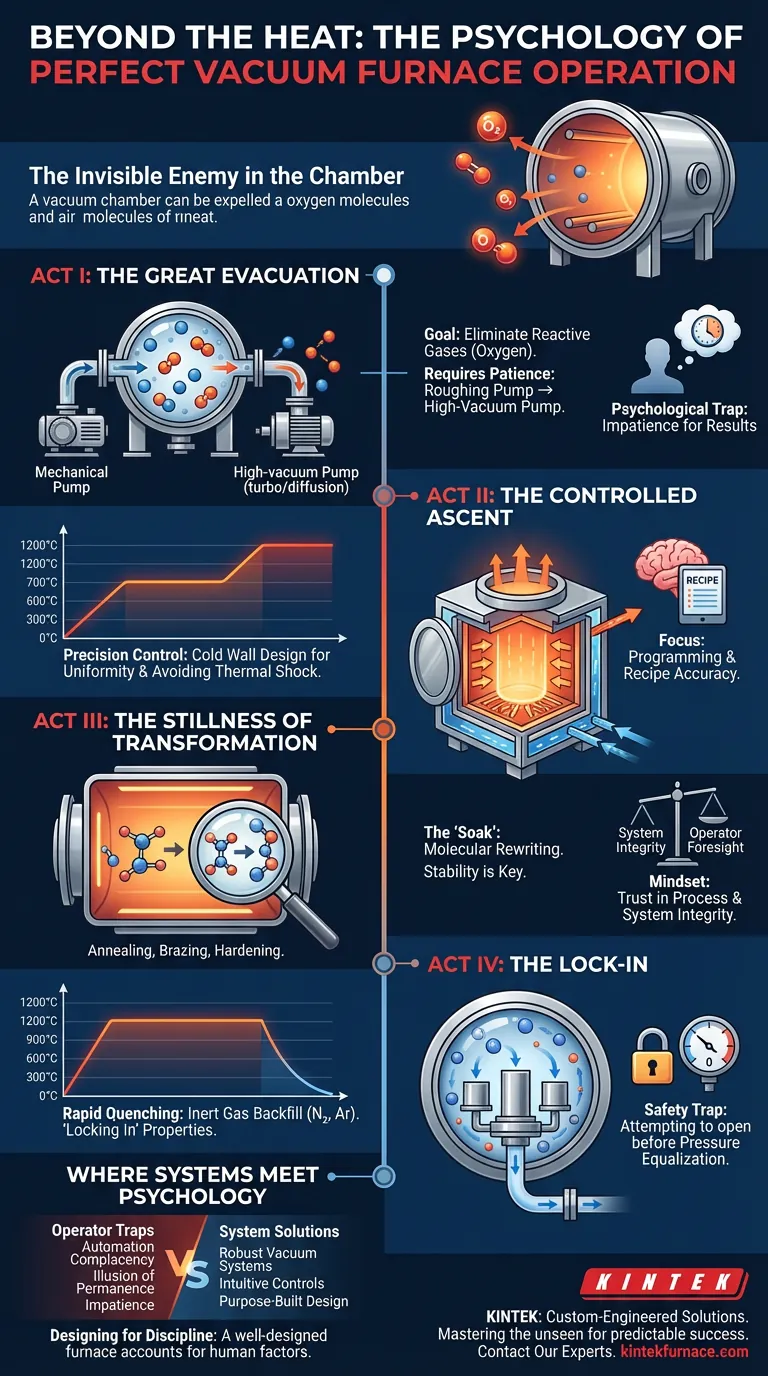

The Four Acts of Environmental Purity

A successful furnace cycle is a narrative in four parts. Each act builds on the last, and a single misstep can compromise the entire performance.

Act I: The Great Evacuation

Before any heat is applied, the chamber must be purged of its atmospheric enemies. The primary goal is to eliminate reactive gases, chiefly oxygen, which cause unwanted chemical reactions at high temperatures.

This is a test of patience. The process involves a mechanical "roughing" pump to remove the bulk of the air, followed by a high-vacuum pump to achieve the deep vacuum required for sensitive processes. The temptation to rush to the heating phase is a cognitive bias we must fight. The quality of this initial emptiness dictates the final quality of the material.

Act II: The Controlled Ascent

Once the target vacuum is achieved, the heating cycle begins. Sophisticated control systems manage the rate of temperature rise with incredible precision. Yet, the system is only as good as the "recipe" programmed by the operator.

Here, the engineering marvel of a "cold wall" design—where the furnace body is water-cooled—allows for rapid and uniform temperature changes. This isn't just about getting hot; it's about arriving at the target temperature without inducing thermal shock, following a path that respects the material's limits.

Act III: The Stillness of Transformation

The "soak" is the quiet heart of the process. The furnace holds the material at a specific temperature for a set duration, allowing for annealing, brazing, or hardening to occur.

This phase is deceptive. To the operator, it appears static. But within the chamber, at a molecular level, the material's very structure is being rewritten. Any instability in vacuum or temperature during this critical period can lead to inconsistent results. It's a testament to the system's integrity and the operator's foresight in programming.

Act IV: The Lock-In

After the soak, the material must be cooled in a highly controlled manner. Modern furnaces often use rapid quenching by backfilling the chamber with an inert gas like nitrogen or argon.

This isn't merely cooling; it is the act of "locking in" the desired physical properties achieved during the soak. An incorrect cooling profile is as damaging as an incorrect heating profile—it can warp parts or fail to achieve the required hardness. The cycle concludes with pressure equalization, a final safety step that protects the operator from their own impatience.

Where Systems Meet Psychology

Even with advanced automation, the operator remains the most critical variable. Success depends on recognizing and mitigating common cognitive traps.

- Automation Complacency: We trust the machine to be perfect. This leads to neglecting essential maintenance, like checking pump oil or cleaning heating elements. A furnace is a precision instrument, and its "brain" (the control system) relies on a healthy "body."

- The Illusion of Permanence: We assume a seal that was good yesterday is good today. A vacuum system demands constant skepticism. Regular leak checks are not chores; they are the foundation of process repeatability.

- Impatience for Results: The desire to see the final product can lead to dangerous shortcuts, like attempting to open the door before pressure has fully equalized. Safety interlocks exist for a reason—they are the system's defense against human nature.

Designing for Discipline and Precision

The most effective way to ensure consistent results is to use equipment that accounts for these human factors. A well-designed furnace doesn't just perform a task; it makes the correct operation the easiest path.

This is where the philosophy behind the hardware becomes critical.

- Robust Vacuum Systems: A furnace with a high-integrity chamber and a reliable pumping system reduces the mental load of leak hunting, allowing the operator to focus on the process itself.

- Intuitive Controls: A clear, logical control interface minimizes the risk of programming errors, ensuring the intended recipe is the one that's executed.

- Purpose-Built Design: For cutting-edge research and critical manufacturing, a one-size-fits-all furnace is a compromise. The process dictates the tool.

For these demanding applications, custom-engineered systems like the KINTEK vacuum furnaces provide a decisive advantage. By tailoring the furnace—from the chamber dimensions to the specific CVD or PECVD capabilities—to the unique requirements of the material, the equipment becomes a true partner. It builds a reliable, repeatable foundation that turns the complex choreography of vacuum, heat, and time into a predictable success.

Mastering the furnace is ultimately about mastering the unseen environment within it. It requires an appreciation for the physics of the vacuum and an honest understanding of the psychology of the operator. With the right perspective and the right tools, you can ensure every cycle delivers perfection.

For processes that demand this level of environmental and operational control, the right partner is essential. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

Related Articles

- The Unseen Enemy: Why Vacuum Furnaces Are a Bet on Perfection

- From Brute Force to Perfect Control: The Physics and Psychology of Vacuum Furnaces

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection