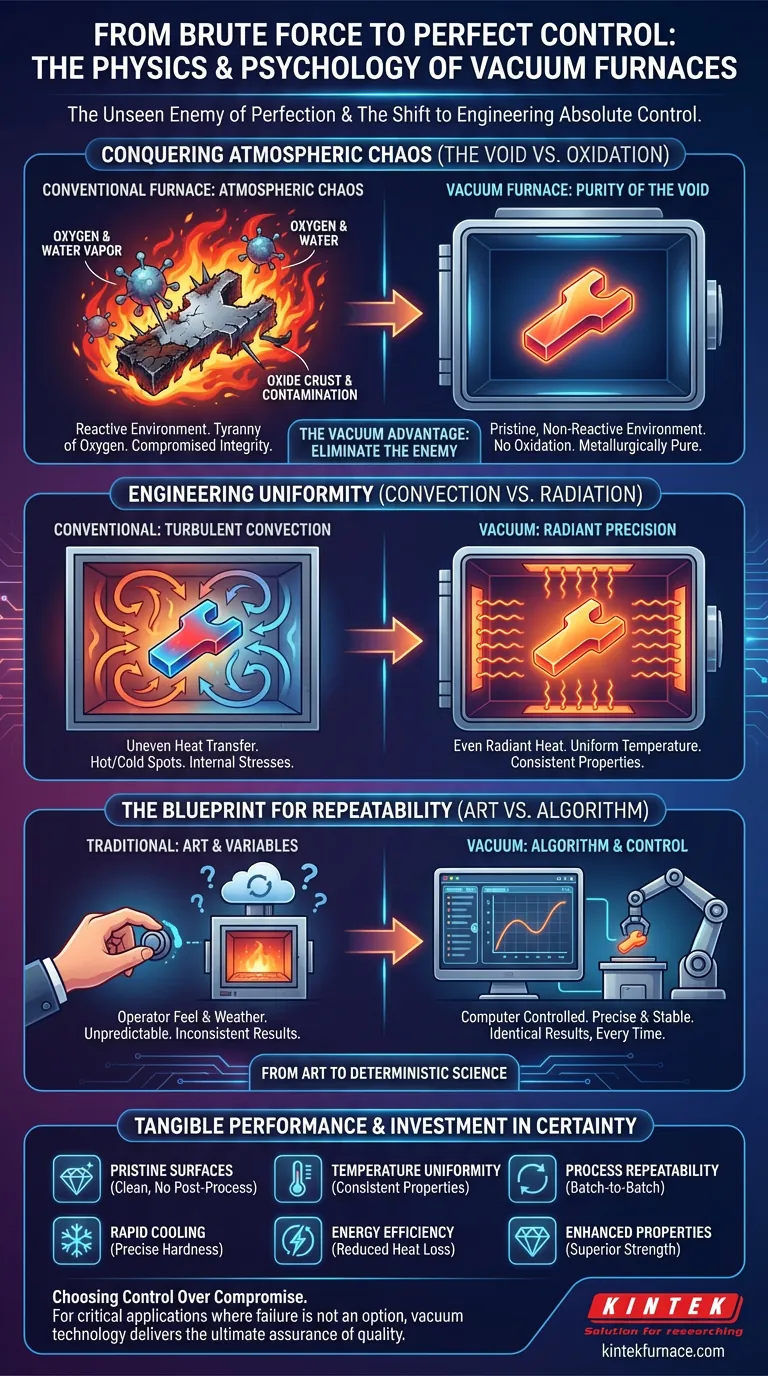

The Unseen Enemy of Perfection

Imagine forging a sword in an open flame. The process is a battle against the elements—the unpredictable flicker of the fire, the impurities in the air, the uneven cooling. Success is a mix of skill, experience, and a healthy dose of luck.

For centuries, this was the essence of metallurgy.

But in the world of high-performance materials, luck is not a variable we can afford. A microscopic oxide inclusion on an aerospace turbine blade or an internal stress point in a medical implant can lead to catastrophic failure.

The fundamental shift in modern material science is a psychological one: a move away from managing chaos and toward engineering absolute control. This is the world of the vacuum furnace. It's not just a piece of equipment; it's a philosophy.

Conquering Atmospheric Chaos

The air we breathe, rich with oxygen and water vapor, is a relentless saboteur at high temperatures. It aggressively attacks hot metal surfaces, seeking to react and contaminate.

The Tyranny of Oxygen

When a material is heated in the atmosphere, it oxidizes. This creates a brittle, discolored surface layer—a crust of imperfection. This isn't just a cosmetic issue; it's a chemical alteration that can compromise the material's structural integrity, conductivity, and performance.

Post-process cleaning can remove the surface layer, but it can't undo the reactions that may have already occurred just below it.

The Purity of the Void

A vacuum furnace wins this battle by simply removing the enemy. By pumping the atmosphere out of the chamber, it creates a pristine, non-reactive environment.

The result is a component that emerges from the heat cycle as clean and bright as it was when it went in. There is no oxidation, no contamination. The material is metallurgically pure, its properties reflecting the design, not the accidents of its processing. This is the elegance of creating in a controlled void.

Engineering Uniformity in an Unforgiving World

Inconsistency is the parent of failure. In a conventional furnace, heat is transferred by convection—the turbulent, swirling currents of hot air. This process is inherently uneven, creating hot and cold spots across the part.

The Fallacy of "Even" Heat

A component treated with uneven heat develops internal stresses. One section expands or contracts differently than another, locking in microscopic weaknesses. The material is left with a hidden legacy of its chaotic thermal history.

Heat by Radiation: A More Perfect Union

A vacuum is a superb insulator. With no air to carry heat via convection, transfer occurs primarily through thermal radiation.

Imagine the part suspended in the center of the hot zone, being bathed evenly by infrared energy from all directions. This is a far more gentle and uniform method of heating. The temperature difference across a complex part can be reduced to just a few degrees, ensuring every feature, curve, and corner receives the exact same thermal treatment.

The Blueprint for Repeatability

Human hands, even the most skilled, introduce variation. Atmospheric conditions change with the weather. How can you guarantee that the part you make today is identical to the one you made last week?

Removing the "Ghost in the Machine"

The "ghost" in traditional heat treatment is the unpredictable variable of the atmosphere. By creating a vacuum, you eliminate this randomness. The process environment becomes a known, stable constant.

From Art to Algorithm

With the environment controlled, the entire thermal cycle can be managed by a computer with absolute precision. Heating rates, soak times, and cooling profiles are not just guidelines; they are code executed flawlessly, time and time again.

This transforms the process from an art reliant on operator feel into a deterministic science. For industries where failure is not an option, this level of metallurgical repeatability is the ultimate assurance of quality.

Tangible Performance, Born from Intangible Control

This disciplined approach translates directly into superior performance and efficiency.

| Advantage | The Practical Impact |

|---|---|

| Pristine Surfaces | Prevents oxidation and contamination, eliminating the need for post-process cleaning. |

| Temperature Uniformity | Ensures consistent material properties and minimizes internal stresses. |

| Process Repeatability | Guarantees identical results from batch to batch, year after year. |

| Rapid Cooling | High-pressure gas quenching allows for precise control over hardness and strength. |

| Energy Efficiency | The vacuum acts as a natural insulator, dramatically reducing heat loss and energy use. |

| Enhanced Properties | Leads to superior strength, ductility, and fatigue life in the final component. |

A Pragmatic View: The Investment in Certainty

Of course, achieving this level of control requires a different class of technology.

A vacuum furnace represents a higher initial investment due to its complex pumps, seals, and control systems. It also demands a higher level of discipline in maintenance to ensure the integrity of the vacuum. The time required to pump down the chamber also adds to the total cycle time.

But these are not deterrents; they are the price of eliminating uncertainty.

Choosing Control Over Compromise

The decision to use a vacuum furnace is a strategic choice to prioritize perfection. For routine applications with wide tolerances, a conventional furnace may suffice.

But for researchers pushing the boundaries of material science, or for manufacturers creating critical components where failure has profound consequences, control is paramount. These applications demand an environment that can be precisely defined and repeated—a promise only a vacuum system can truly deliver.

At KINTEK, we build the tools for those who choose control. Our deep expertise in R&D and manufacturing allows us to deliver highly customizable high-temperature solutions, from Vacuum and CVD systems to Tube and Rotary furnaces. We understand that your work depends on creating the perfect environment for innovation.

Let us help you eliminate the variables and engineer perfection. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

Related Articles

- The Unseen Enemy: Why Vacuum Furnaces Are a Bet on Perfection

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection

- The Real Reason Your High-Performance Materials Are Failing (And It’s Not the Alloy)

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design