You’ve done everything by the book. You selected a cutting-edge alloy, meticulously prepared the sample, and programmed the heat treatment cycle exactly to specification. Yet, when you inspect the final part, it’s a failure. Perhaps it’s discolored, brittle where it should be strong, or warped just enough to be useless. You’re left with a scrapped, expensive component and a frustrating question: what went wrong?

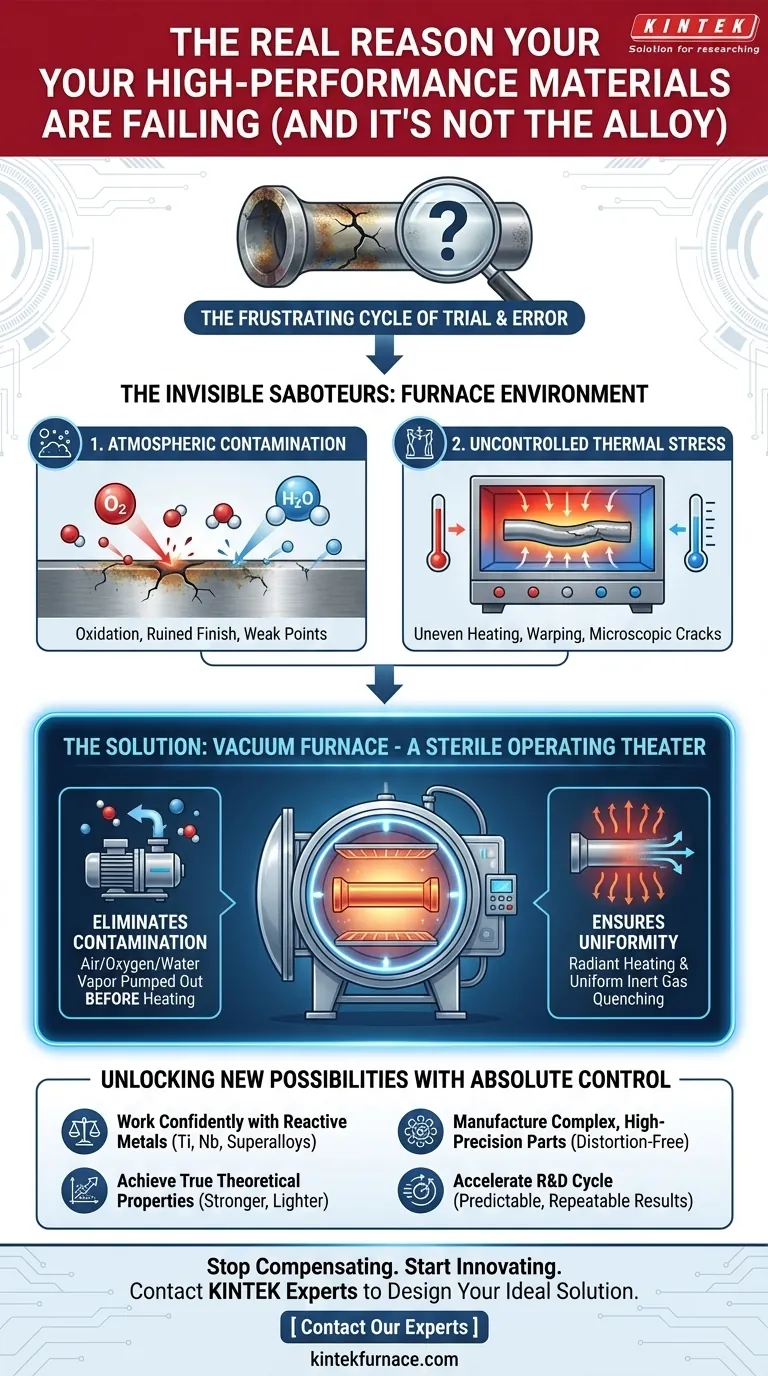

The Frustrating Cycle of Trial and Error

If this scenario sounds familiar, you are not alone. Across aerospace, medical device, and advanced manufacturing labs, teams are caught in a costly cycle of trial and error. They chase consistency by tweaking the obvious variables:

- Adjusting the peak temperature by a few degrees.

- Extending the “soak” time.

- Slowing down the cooling rate.

- Questioning the raw material supplier.

Sometimes these adjustments seem to work, only for the problem to reappear in the next batch. This isn't just a technical nuisance; it has severe business consequences. Each failed cycle wastes valuable materials, consumes expensive energy, and—most critically—delays R&D projects and pushes back product launch dates. The inability to get predictable, repeatable results puts a hard ceiling on innovation.

The Invisible Saboteurs: Why Your Furnace Environment is the Real Problem

The frustrating truth is that these adjustments rarely work consistently because they focus on the symptoms, not the underlying disease. The problem isn’t your recipe; it’s the "kitchen" you're cooking in.

In any conventional atmosphere furnace, even one purged with inert gas, two invisible saboteurs are always at work:

1. Atmospheric Contamination

The air around us contains about 21% oxygen and traces of water vapor. When heated to high temperatures, these molecules become hyper-reactive. They attack the surface of your materials, causing micro-oxidation that ruins surface finish, compromises brazed joints, and creates weak points that lead to premature failure. Even a "high-purity" inert gas purge in a standard furnace can't eliminate this entirely, leaving residual contaminants to compromise your work.

2. Uncontrolled Thermal Stress

Atmosphere furnaces transfer heat primarily through convection—the movement of hot gas. This process is inherently uneven, creating hot and cold spots across your component. During heating and, more importantly, during cooling, these temperature differences cause different parts of the material to expand and contract at different rates. This introduces internal stress, leading to warping, distortion, and even microscopic cracks that are invisible to the eye but catastrophic under load.

Tweaking the temperature does nothing to remove the oxygen. Extending the soak time can’t fix a hot spot. You are fighting a battle you can't win because the fundamental environment is flawed.

The Solution: A Sterile Operating Theater for Your Materials

To defeat these two culprits, you don't need a slightly better furnace. You need a fundamentally different approach—one that provides total control over the thermal environment. This is the core principle behind a vacuum furnace. It is less like an oven and more like a sterile operating theater for materials science.

A vacuum furnace directly neutralizes both saboteurs:

- It eliminates contamination: By pumping out the air, the vacuum removes the oxygen and water vapor before the heating process even begins. Heat is then transferred through pure radiation in an ultra-clean environment, ensuring the material’s surface remains pristine and its inherent properties are preserved.

- It ensures perfect uniformity: Radiant heating in a vacuum is incredibly uniform, bathing the entire component in even energy. This eliminates hot spots. Then, for cooling, high-purity inert gas is introduced and circulated at high velocity, quenching the part evenly from all sides. This controlled, uniform process minimizes thermal shock and stress, virtually eliminating warping and distortion.

How KINTEK Vacuum Furnaces Deliver Absolute Control

A KINTEK vacuum furnace is the embodiment of this philosophy. It's not just a box that gets hot; it's an integrated system engineered to give you precise, repeatable command over the entire thermal cycle.

Our systems are designed to provide the exceptional uniformity and high-purity environment needed to process the most sensitive and high-value materials. Because we handle our own R&D and in-house manufacturing, we have the deep technical expertise to customize a furnace that precisely matches your material, your process, and your goals, ensuring the "sterile operating theater" is perfectly equipped for your specific procedure.

Beyond Damage Control: Unlocking New Material Possibilities

When you can finally trust your heat treatment process, everything changes. This isn't just about preventing failures; it's about unlocking potential.

With the absolute control a vacuum furnace provides, you can:

- Confidently work with reactive metals like titanium, niobium, and advanced superalloys without fear of oxidation.

- Achieve the true, theoretical properties of your materials, resulting in stronger, lighter, and more durable components.

- Manufacture complex, high-precision parts that are free from distortion, dramatically reducing the need for costly post-processing and machining.

- Accelerate your R&D cycle because your results are no longer a mystery. They are predictable and repeatable, every single time.

You can finally move from compensating for your furnace's limitations to exploring the true limits of your materials.

Solving process inconsistency is more than a technical victory; it’s a strategic advantage that accelerates innovation and improves your bottom line. Whether you're developing next-generation aerospace components, pioneering new medical implants, or scaling up production of advanced electronics, getting the thermal process right is paramount. Our team of experts can help you design the ideal solution to overcome your unique challenges and achieve results you can finally depend on. To discuss your project, Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Related Articles

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection

- From Brute Force to Perfect Control: The Physics and Psychology of Vacuum Furnaces

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation