Atmosphere Furnace

1700℃ Controlled Inert Nitrogen Atmosphere Furnace

Item Number : KT-17A

Price varies based on specs and customizations

- Max. temperature

- 1700℃

- Heating element

- Molybdenum Disilicide

- Temperature control accuracy

- ±1℃

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Detail & Parts

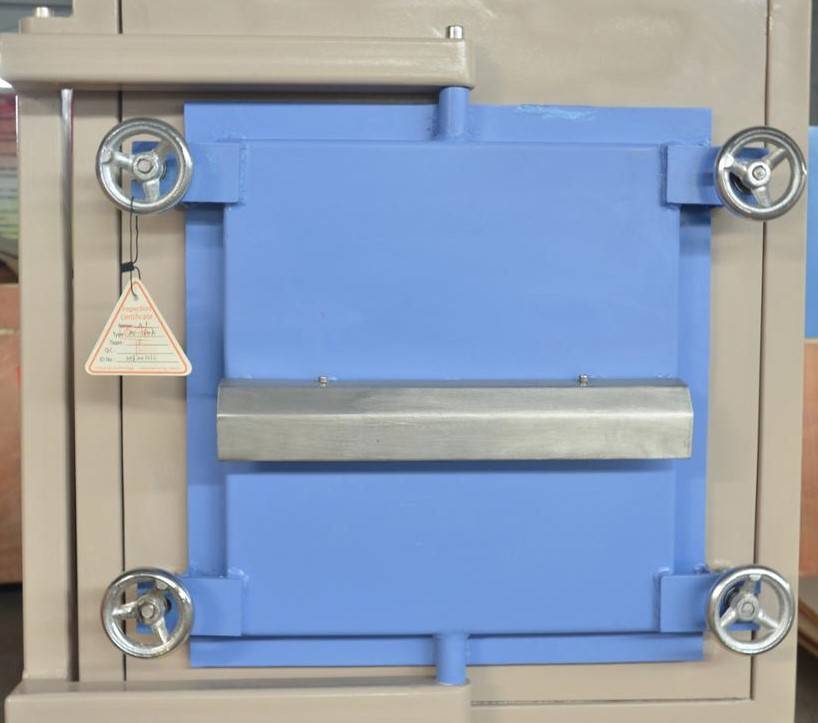

Introducing the KT-17A Controlled Atmosphere Furnace

The KINTEK KT-17A Controlled Atmosphere Furnace is engineered for versatility, serving demanding laboratory and industrial applications. It boasts a heavy-duty vacuum chamber structure and a scientifically united control panel for precise vacuum suction, inert gas pressure, and flow management. The innovative double furnace shell design, coupled with forced air flow cooling, effectively controls the furnace surface temperature for enhanced safety and operational comfort. With PID programmable temperature control, the KT-17A ensures excellent control accuracy. Energy efficiency is paramount, achieved through a ceramic polycrystalline fiber insulation liner that minimizes heat loss. Professional-grade heating elements are optimized for superior heat radiation and extended service life. For operational safety, an interlock system automatically shuts off power if the furnace door is opened, an over-temperature condition occurs, or a sensor malfunctions. The KT-17A Pro model elevates user experience with a 7-inch TFT smart touch screen controller, enabling friendly program setting and insightful history data analysis.

Key Features & Advantages for Your Advanced Processes

The KT-17A Controlled Atmosphere Furnace is designed to deliver exceptional performance, efficiency, and safety for your high-temperature processes:

- Precise Atmosphere Control: Features a sealed housing with silicon gel sealed cover and door, water cooling system, and flow meters for meticulous management of various atmospheres (H2, Ar, N2, O2, CO, NH3) after pre-vacuuming. This ensures optimal conditions for sensitive material processing.

- Rapid Heating & Cooling: The double-layer housing with a wind cooling system facilitates quick temperature adjustments, improving process efficiency and reducing downtime.

- Uniform Temperature Field: Ensures consistent temperature distribution throughout the chamber, critical for reproducible results in sintering, reducing, and other heat treatment processes.

- Advanced Temperature Management: Equipped with a Shimaden FP93 controller (or optional touch screen), supporting 40 programmable segments for complex heating profiles tailored to specific material requirements up to 1700°C.

- Energy Efficiency & Durability: Utilizes high-quality Kantal resistance wire heating elements (Molybdenum Disilicide for 1700°C model) and a polycrystalline alumina fibre chamber for excellent thermal insulation, minimal heat loss, and long service life.

- Low Surface Temperature: The double-layer housing and cooling system keep the exterior surface temperature low, enhancing operator safety.

Versatile Applications in Research and Industry

The Controlled Atmosphere Furnace is an indispensable tool for a wide array of high-temperature processes that demand precise atmosphere control. It is ideally suited for:

- Atmosphere Protection Sintering: Perfect for sintering materials under controlled atmospheres to prevent oxidation and enhance material properties.

- Atmosphere Reducing Processes: Essential for processes requiring an oxygen-reduced environment, such as in the manufacturing of specific alloys or ceramics.

- Material Research and Development: A vital instrument for researchers investigating the impact of controlled atmospheres on material characteristics and behaviors.

- Small Batch Production: Highly effective for producing semiconductors, silicon nitride, and other materials where stringent atmosphere control is crucial.

- Educational Purposes: Offers invaluable hands-on experience for students in materials science and engineering, illustrating the practical applications of controlled atmosphere furnaces in industrial settings, scientific research institutes, and universities.

Operating Principle: Precision Atmosphere Control

The KT-17A Controlled Atmosphere Furnace operates using an airtight, vacuum-sealed heating chamber. Within this robust vacuum chamber, similar to a vacuum glove box, reside the insulation chamber and heating elements. Users first evacuate the chamber to a negative pressure of -0.1Mpa using a vacuum pump. Subsequently, inert or specific process gases are introduced to create the desired controlled atmosphere. The furnace is equipped with vacuum pressure gauges, vacuum suction ports with valves, gas purging ports with valves, and float flowmeters, ensuring precise control for both laboratory and industrial applications.

Advanced Safety Features for Peace of Mind

KINTEK prioritizes safety in all our furnace designs:

- Over-Current and Over-Temperature Protection: The furnace is equipped with over-current protection and an over-temperature alarm function, automatically shutting off power if limits are exceeded.

- Thermal Couple Failure Detection: A built-in thermal couple detecting function will stop heating and trigger an alarm if a sensor breakage or failure is detected.

- Power Failure Restart (KT-17A Pro): The KT-17A Pro model supports a power failure restarting function, allowing the furnace to resume its heating program automatically once power is restored.

- Door Safety Interlock: Power is automatically cut off if the furnace door is opened during operation.

Technical Specifications

| Furnace model | KT-17A | ||

|---|---|---|---|

| Max. temperature | 1700℃ | ||

| Constant work temperature | 1600℃ | ||

| Vacuum pressure | -0.1Mpa | ||

| Vacuum valve | Needle valve | ||

| Chamber material | Japan alumina fiber | ||

| Heating element | Molybdenum Disilicide | ||

| Heating rate | 0-20℃/min | ||

| Temperature sensor | B type thermal couple | ||

| Temperature controller | Digital PID controller/Touch screen PID controller | ||

| Temperature control accuracy | ±1℃ | ||

| Temperature uniformity | ±5℃ | ||

| Electric power supply | AC110-220V,50/60HZ | ||

| Standard Chamber Sizes Stocks | |||

| Chamber size (mm) | Effective volume (L) | Chamber size (mm) | Effective volume (L) |

| 100x100x100 | 1 | 300x300x400 | 36 |

| 120x120x130 | 2 | 400x400x400 | 64 |

| 150x150x200 | 4.5 | 500x500x500 | 125 |

| 200x200x200 | 8 | 600x600x600 | 216 |

| 200x200x300 | 12 | 800x800x800 | 512 |

| Customer design sizes and volume is accepted | |||

Standard Package & Optional Enhancements

Standard Package

| No. | Description | Quantity |

|---|---|---|

| 1 | Furnace | 1 |

| 2 | Thermal block | 1 |

| 3 | Crucible tong | 1 |

| 4 | Heat resistant glove | 1 |

| 5 | Operation manual | 1 |

Optional Setup

- Independent furnace temperature monitoring and recording

- RS 485 communication port for PC remote control and data exporting

- Insert gases port, exhaust output port, observation window port

- Touch screen temperature controller with versatile operator friendly functions (Standard on KT-17A Pro)

Why Partner with KINTEK for Your Furnace Needs?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and industrial facilities with advanced high-temperature furnace solutions. Our comprehensive product line, including Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and specialized CVD/PECVD/MPCVD Systems, is designed to meet a wide range of thermal processing requirements. What truly sets us apart is our strong deep customization capability, allowing us to precisely tailor solutions to meet your unique experimental or production requirements. When you choose KINTEK, you're investing in quality, innovation, and a partnership dedicated to your success.

Request Your Customized Furnace Solution

Ready to elevate your high-temperature processes with the KT-17A Controlled Atmosphere Furnace or a custom-designed solution? Our experts are here to help you define the perfect configuration for your needs. To discuss your specific requirements, explore customization options, or receive a detailed quote, please contact us today. Let KINTEK empower your research and production goals.

Trusted by Industry Leaders

FAQ

What Is An Atmosphere Furnace Used For?

What Is The Principle Of A Hot Press Furnace?

What Are The Key Features Of An Atmosphere Furnace?

What Are The Applications Of A Hot Press Furnace?

How Does An Atmosphere Furnace Work?

What Are The Features Of A Hot Press Furnace?

What Are The Advantages Of Using An Atmosphere Furnace?

Why Is A Vacuum Environment Used In Hot Press Furnaces?

What Types Of Gases Can Be Used In An Atmosphere Furnace?

What Materials Are Commonly Processed In Hot Press Furnaces?

What Safety Features Are Available In Advanced Atmosphere Furnaces?

4.9 / 5

Incredible precision and durability! This furnace exceeded all my expectations. A game-changer for my lab!

4.8 / 5

Fast delivery and top-notch quality. The nitrogen control is flawless. Worth every penny!

4.7 / 5

The temperature control is spot-on. Perfect for high-temperature experiments. Highly recommend!

4.9 / 5

Built like a tank and performs like a dream. The inert atmosphere feature is a lifesaver!

4.8 / 5

Superior technology at an affordable price. My research has never been smoother!

4.9 / 5

Exceptional furnace with precise temperature control. Delivered faster than expected!

4.7 / 5

Reliable and efficient. The nitrogen atmosphere works perfectly. No regrets!

4.8 / 5

High-quality construction and advanced features. A must-have for serious researchers!

4.9 / 5

Absolutely love this furnace! The 1700℃ capability is a game-changer. Fast shipping too!

4.8 / 5

Perfect for my high-temperature needs. The inert atmosphere is flawless. Great value!

4.7 / 5

Impressive build and performance. The nitrogen control is precise. Highly satisfied!

4.9 / 5

Top-tier furnace with unbeatable features. Delivered on time and works like a charm!

4.8 / 5

The furnace is a beast! Handles 1700℃ with ease. Nitrogen atmosphere is perfect. Love it!

4.7 / 5

Excellent product for the price. The temperature stability is outstanding. Very happy!

4.9 / 5

A masterpiece of engineering. The inert nitrogen feature is flawless. Delivery was lightning fast!

4.8 / 5

High-performance furnace with precise control. The nitrogen atmosphere is a huge plus. Fantastic!

4.7 / 5

Superb quality and performance. The 1700℃ capability is a dream come true. Highly recommend!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

KINTEK Mesh Belt Furnace: High-performance controlled atmosphere furnace for sintering, hardening & heat treatment. Customizable, energy-efficient, precise temperature control. Get a quote now!

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision high-temperature processing up to 2000°C for labs. Ideal for material synthesis, CVD, and sintering. Customizable options available.

1700℃ High Temperature Muffle Oven Furnace for Laboratory

KT-17M Muffle Furnace: High-precision 1700°C lab furnace with PID control, energy efficiency, and customizable sizes for industrial & research applications.

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Laboratory Muffle Oven Furnace with Bottom Lifting

Boost lab efficiency with KT-BL Bottom Lifting Furnace: precise 1600℃ control, superior uniformity, and enhanced productivity for material science and R&D.

1200℃ Muffle Oven Furnace for Laboratory

KINTEK KT-12M Muffle Furnace: Precision 1200°C heating with PID control. Ideal for labs needing rapid, uniform heat. Explore models & customization options.

1400℃ Muffle Oven Furnace for Laboratory

KT-14M Muffle Furnace: Precision 1400°C heating with SiC elements, PID control, and energy-efficient design. Ideal for labs.

1800℃ High Temperature Muffle Oven Furnace for Laboratory

KINTEK Muffle Furnaces: Precision 1800°C heating for labs. Energy-efficient, customizable, with PID control. Ideal for sintering, annealing, and research.

Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

High-performance MoSi2 heating elements for labs, reaching 1800°C with superior oxidation resistance. Customizable, durable, and reliable for high-temperature applications.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

Advanced PECVD Tube Furnace for precise thin film deposition. Uniform heating, RF plasma source, customizable gas control. Ideal for semiconductor research.

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Precision rotary tube furnace for continuous vacuum processing. Ideal for calcination, sintering, and heat treatment. Customizable up to 1600℃.

Vertical Laboratory Quartz Tube Furnace Tubular Furnace

Precision KINTEK Vertical Tube Furnace: 1800℃ heating, PID control, customizable for labs. Ideal for CVD, crystal growth & materials testing.

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

1400℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-14A Controlled Atmosphere Furnace for labs & industry. 1400°C max temp, vacuum sealing, inert gas control. Customizable solutions available.

1200℃ Controlled Inert Nitrogen Atmosphere Furnace

KINTEK 1200℃ Controlled Atmosphere Furnace: Precision heating with gas control for labs. Ideal for sintering, annealing, and material research. Customizable sizes available.

Related Articles

Why Your High-Temperature Materials Fail: The Hidden Enemy in Your Furnace

Discover why your heat treatments yield inconsistent results. It's not just the heat—it's the uncontrolled atmosphere. Learn how to fix it.

Why Your High-Temp Experiments Fail: It’s Not the Heat, It’s the Atmosphere

Frustrated by inconsistent results? Discover why the furnace atmosphere, not just temperature, is the key to success in heat treatment and materials science.

In Pursuit of Purity: The Silent Power of the Vacuum Furnace

Explore why vacuum furnaces are critical for processing reactive metals and alloys. It's not about heat, but controlling the unseen enemy: atmosphere.

The Hidden Flaw in Your Heat Treatment: It’s Not the Temperature, It’s the Air

Discover why your heat-treated components fail despite perfect recipes. The root cause isn't temperature—it's the atmosphere. Learn how to fix it.

The Invisible Contaminant: Why Your Furnace Atmosphere is Sabotaging Your Results

Struggling with inconsistent results from your high-temp processes? Discover the hidden contaminant sabotaging your work and how to fix it for good.

Beyond Heat: The Unseen Power of Environmental Control in Tube Furnaces

Discover why the true value of a tube furnace isn't just temperature, but the absolute environmental control it offers for repeatable science.

The Physics of Absence: How Vacuum Furnaces Defy the Limits of Heat

Discover how vacuum furnaces overcome oxidation, enabling temperatures up to 3000°C for advanced materials processing by removing the very air that fuels fire.

The Engineer's Gambit: Why Vacuum Furnaces Are About Control, Not Just Heat

Explore the physics and psychology behind vacuum furnaces, where eliminating atmospheric chaos enables surgically precise, repeatable heat treatment.

The Alchemy of Isolation: Why Tube Furnaces Are Indispensable for Innovation

Explore how a tube furnace's true value lies not in heat, but in creating isolated, controlled environments for advanced materials science and innovation.

More Than a Box: The Engineering Philosophy Behind High-Integrity Vacuum Furnaces

Explore the engineering philosophy behind a vacuum furnace chamber, where material science and thermal dynamics meet to create a perfectly controlled void.

Mastering the Void: The Physics and Psychology of Vacuum Furnaces

Vacuum furnaces offer more than purity; they provide absolute control over a material's environment, preventing unseen reactions to unlock its potential.

The Cascading Logic of Safety: Rethinking the Modern Vacuum Furnace

True vacuum furnace safety isn't a feature list, but a multi-layered system designed to manage risk, prevent cascading failures, and account for human error.