You’ve done everything by the book. The metallurgy is correct, the temperature profile is precise, and the cooling rate is perfect. Yet, the final component pulled from your furnace is a disappointment. It’s slightly warped, the surface is discolored with an oxide layer, or worse, it fails under stress tests, exhibiting unexpected brittleness. You're left standing with a scrapped part and a nagging question: what went wrong?

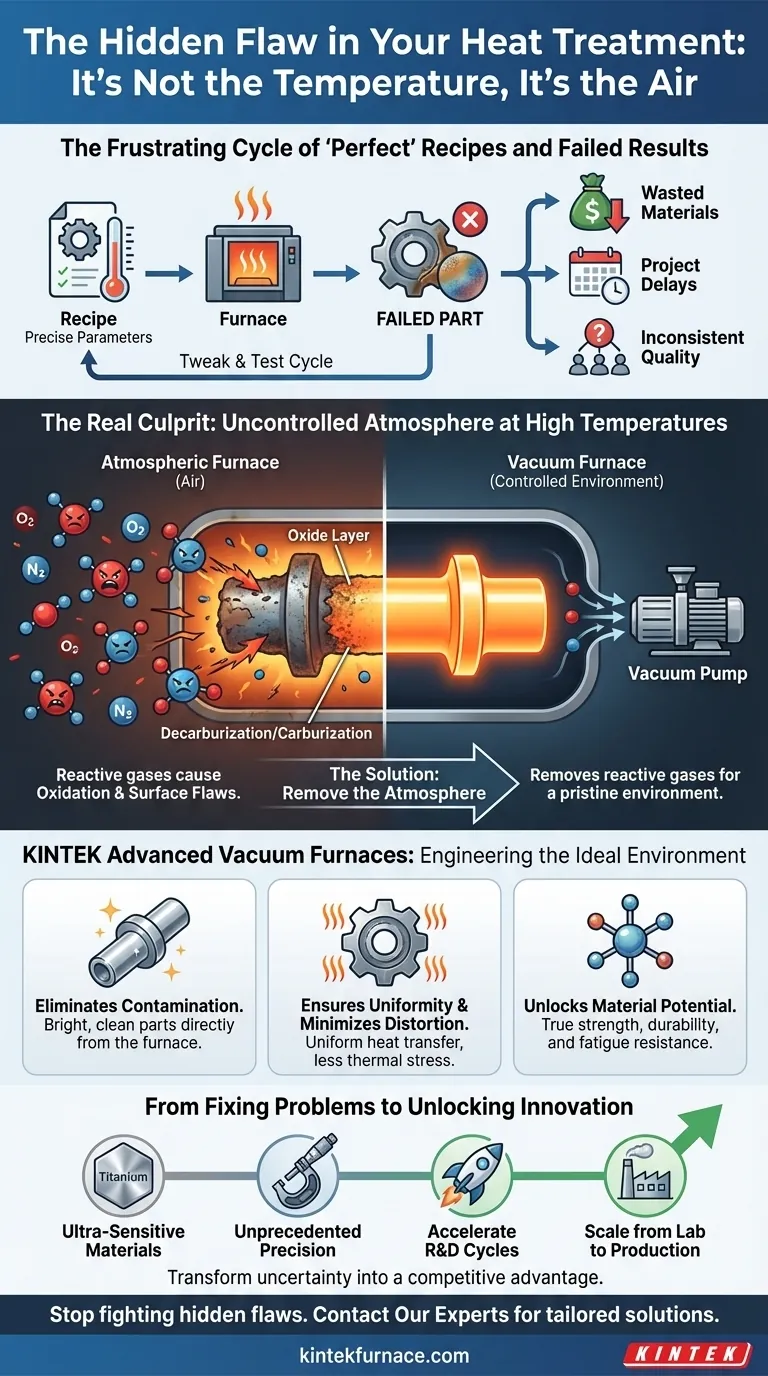

The Frustrating Cycle of 'Perfect' Recipes and Failed Results

This isn't an isolated incident; it's a chronic struggle in many advanced R&D labs and production lines. When high-performance materials don't meet specifications after heat treatment, the immediate reaction is to scrutinize the recipe. Was the temperature ramp too fast? Was the holding time too short? Should we try a slightly different alloy composition?

This cycle of 'tweak and test' begins. Engineers spend weeks adjusting parameters, running countless cycles, and analyzing failed parts. Each failed batch carries a significant cost:

- Wasted Materials: High-performance alloys and ceramics are expensive. Every scrapped component is money vaporized.

- Project Delays: The time lost on troubleshooting pushes back development timelines, delaying product launches and impacting commitments.

- Inconsistent Quality: Even when a successful result is achieved, it’s often difficult to replicate, leading to unreliable product performance and potential reputational damage.

These aren't just technical frustrations; they are significant business roadblocks. The core issue is that these common "solutions" are merely treating the symptoms, because the diagnosis is wrong. The problem often isn't your recipe.

The Real Culprit: Uncontrolled Atmosphere at High Temperatures

The true saboteur of your process is often invisible: the air inside your furnace.

At ambient temperatures, the gases in our atmosphere—primarily nitrogen and oxygen—are relatively harmless to most materials. But at the high temperatures required for heat treatment, everything changes. The material’s surface becomes highly reactive, and the air transforms from a benign environment into a source of contamination.

Here’s the simple science behind the failure:

- Oxidation: Oxygen atoms in the air aggressively bond with the metal surface, creating a brittle, often discolored, oxide layer. This layer not only ruins the surface finish but can also compromise the structural integrity of the component.

- Decarburization/Carburization: For steels, the carbon content is critical for its hardness and strength. Gases in the atmosphere can react with the steel, either stripping carbon from its surface (decarburization, making it soft) or adding excess carbon (carburization, making it brittle).

Tweaking your temperature profile will never solve this because you’re not addressing this fundamental chemical problem. It’s like trying to bake a world-class cake in a dusty room; no matter how perfect your recipe, the final product will always be contaminated. The common "solutions" fail because they operate within a flawed environment.

Solving the Root Cause: Engineering the Ideal Treatment Environment

If the root cause is unwanted chemical reactions with the atmosphere, the logical solution is to remove the atmosphere entirely. This is where the process shifts from guesswork to precision engineering. To achieve pristine, repeatable results, you need a tool specifically designed to eliminate this fundamental variable.

This is the principle behind a vacuum furnace.

A vacuum furnace isn’t just a box that gets hot; it's a highly controlled environment. By pumping out the air before the heating cycle begins, it removes the reactive gases that cause oxidation and decarburization. Inside this clean, inert environment, the heat treatment process can proceed exactly as intended, without any unwanted side reactions.

KINTEK's advanced vacuum furnaces are the embodiment of this principle. They are designed not just to deliver heat, but to create the perfect conditions for that heat to work its magic.

- Directly Eliminates Contamination: The vacuum environment directly addresses the root cause of oxidation and surface flaws, resulting in bright, clean parts straight from the furnace.

- Ensures Uniformity and Minimizes Distortion: In the absence of air currents, heat transfer is more uniform, minimizing the thermal stress that causes warping and distortion in complex geometries.

- Unlocks Material Potential: The process ensures the material's final properties—strength, durability, and fatigue resistance—are a direct result of your carefully designed thermal cycle, not a lottery of atmospheric reactions.

Furthermore, because every advanced material has unique requirements, our deep customization capabilities ensure your furnace is not just a standard product, but a solution precisely tailored to your specific experimental or production goals.

From Fixing Problems to Unlocking Innovation

When you eliminate the variable of atmospheric contamination, you do more than just solve a quality issue. You unlock new capabilities. The conversation in your lab shifts from "Why did this fail?" to "What can we achieve next?"

With a reliable and pristine heat treatment environment, you can:

- Work with Ultra-Sensitive Materials: Confidently process reactive metals like titanium, superalloys, and refractory metals that are impossible to treat in a conventional furnace.

- Achieve Unprecedented Precision: Manufacture components for demanding industries like aerospace, medical implants, and high-performance electronics where dimensional accuracy and material integrity are non-negotiable.

- Accelerate R&D Cycles: Move from trial-and-error to predictable, repeatable results, drastically shortening the time it takes to develop and qualify new products and processes.

- Scale from Lab to Production: Seamlessly transfer a process perfected in an R&D vacuum furnace to a larger production system, knowing the results will be consistent.

By moving beyond simply managing symptoms, you can finally take full control of your material outcomes. This transforms your heat treatment process from a source of uncertainty into a competitive advantage.

Stop fighting the hidden flaws in your process. It’s time to address the root cause and unlock the true potential of your materials. If you are struggling with inconsistent results or looking to push the boundaries of what's possible, our team of experts can help you design the ideal thermal processing solution for your specific challenges. Let's discuss how to move your project from frustration to breakthrough. Contact Our Experts.

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

Related Articles

- Beyond Temperature: Mastering the Invisible Environment in a Tube Furnace

- The Invisible Contaminant: Why Your Furnace Atmosphere is Sabotaging Your Results

- The Engineer's Gambit: Why Vacuum Furnaces Are About Control, Not Just Heat

- The Controlled Universe: Mastering Matter Inside a 70mm Tube Furnace

- From Powder to Power: The Physics of Control in a Tube Furnace