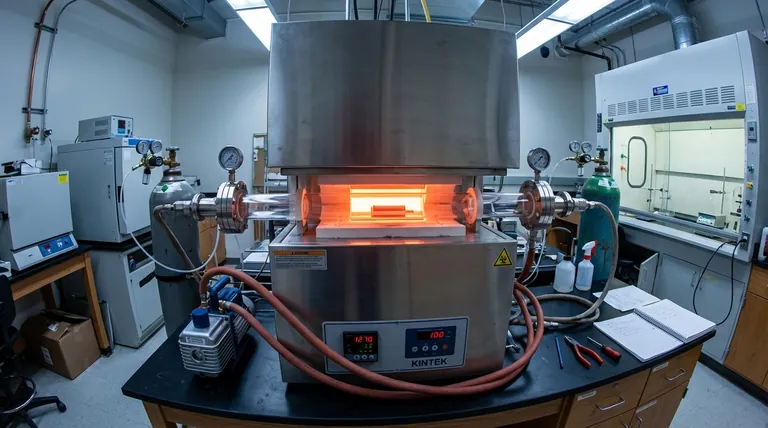

The Promise and Peril of High-Temperature Processing

At its heart, science is about control. We seek to create environments where variables can be isolated and phenomena can be observed repeatably. But as we raise the temperature, this control becomes fragile. Materials that are stable at room temperature begin to react, oxidize, and degrade in unpredictable ways.

The challenge isn't just getting something hot. The real challenge is to heat it precisely while protecting it from the chaotic, reactive nature of a high-temperature atmosphere. This is the fundamental problem a tube furnace was engineered to solve.

An Architecture of Isolation

The elegance of a tube furnace lies not in its complexity, but in its deliberate simplicity. Its design is an architecture of isolation, built around one core principle: physically separating the heat source from the sample being processed.

This separation is the key to everything. It prevents contamination and enables a level of environmental control that direct heating methods can't match.

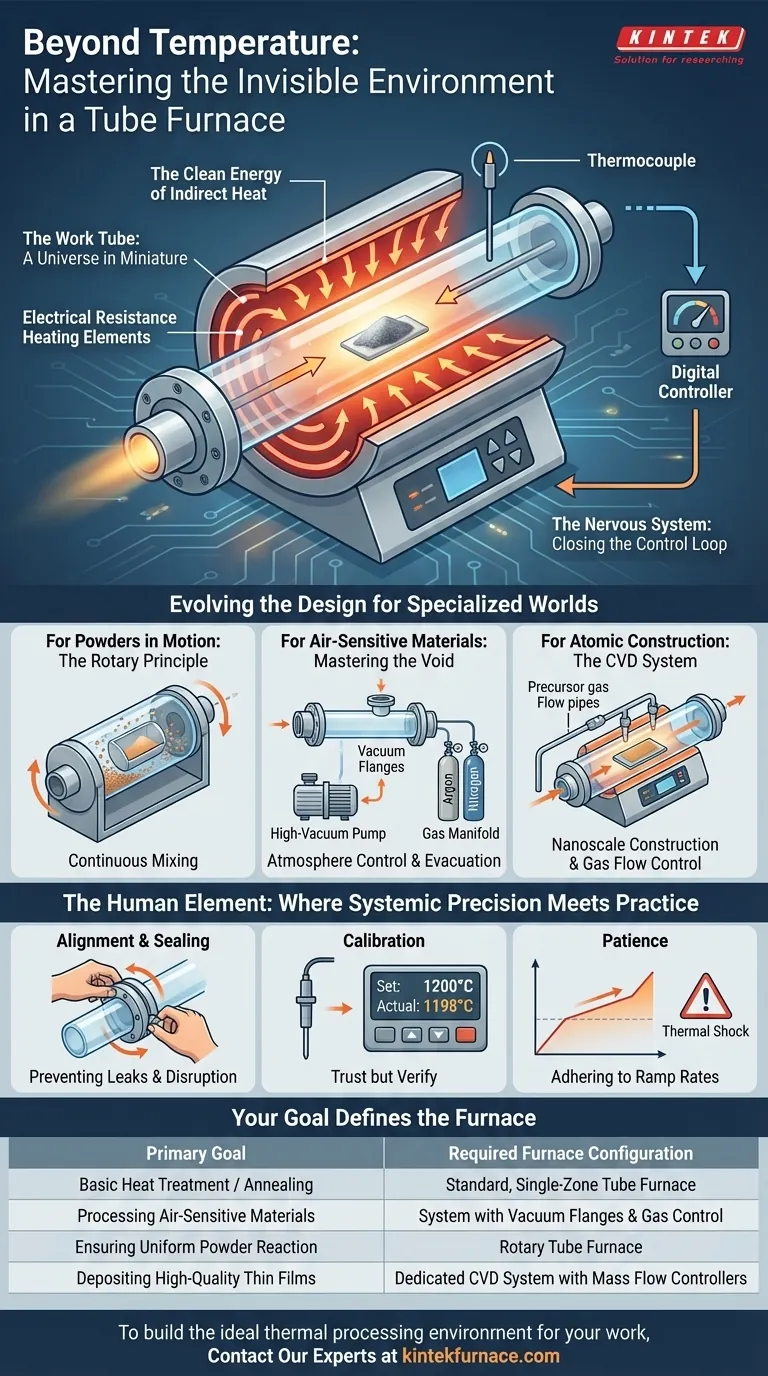

The Work Tube: A Universe in Miniature

The heart of the system is the work tube, typically made of quartz or alumina. It is more than just a container; it is a self-contained universe for your sample.

By sealing the ends with specialized flanges, this simple tube is transformed into a hermetic chamber. Inside, you are the master of the environment. You can create a near-perfect vacuum or introduce a meticulously composed atmosphere of inert or reactive gases. The sample exists only in the world you design for it.

The Clean Energy of Indirect Heat

Surrounding the work tube are electrical resistance heating elements. They are the furnace's engine, but they never touch the sample. They pour thermal energy into the chamber, which radiates inward, heating the tube's surface uniformly.

This heat is then conducted through the tube wall to the sample. The process is clean, indirect, and remarkably even, ensuring the material is heated from all sides without thermal gradients that could ruin an experiment.

The Nervous System: Closing the Control Loop

Human intuition is useless at 1200°C. To impose order, the furnace relies on a digital feedback loop—its nervous system.

A thermocouple, placed near the work tube, constantly measures the temperature. It reports this data back to a digital controller, which compares the reality to the desired setpoint. The controller then adjusts the power to the heating elements with relentless precision. This loop is what turns a crude oven into a scientific instrument.

Evolving the Design for Specialized Worlds

While the principle of isolation is universal, the architecture must adapt to the specific goal. This is where standard designs evolve into highly specialized tools, and where the need for expert customization becomes critical.

For Powders in Motion: The Rotary Principle

Heating a static powder in a crucible is fraught with inconsistency. The grains on top get the full exposure, while those at the bottom remain insulated.

A rotary tube furnace solves this by introducing motion. The entire tube rotates at a slight angle, causing the material to tumble and mix continuously. This ensures every single particle is exposed to the same temperature and atmosphere, guaranteeing a uniform reaction.

For Air-Sensitive Materials: Mastering the Void

For materials that would instantly oxidize in air, atmosphere control is non-negotiable. A furnace system must be equipped with high-vacuum pumps and gas manifolds.

The process involves first removing the existing world—evacuating all the air—and then building a new one by backfilling with a pure, specific gas like argon or nitrogen. This is essential for modern materials science, from battery research to alloy development.

For Atomic Construction: The CVD System

A Chemical Vapor Deposition (CVD) furnace represents the pinnacle of this design philosophy. Here, the goal is not just to treat a material but to build one from the atoms up.

Precursor gases are flowed through the heated tube at precisely controlled rates. The heat catalyzes a reaction, causing a solid thin film to "grow" on a substrate's surface. This demands the highest integration of temperature, pressure, and gas flow control, turning the furnace into a nanoscale construction site.

The Human Element: Where Systemic Precision Meets Practice

A perfectly designed instrument can still produce flawed results. The operator's discipline is the final, crucial component in the system of control.

The Physics of Alignment and Sealing

The work tube must be perfectly centered, never touching the furnace walls. A leaky flange, tightened unevenly, can undo the most sophisticated vacuum system. These are not minor details; they are fundamental points of failure that disrupt the entire isolated environment.

The Psychology of Calibration: Trust but Verify

The number on the controller's display is a measurement, not the absolute truth. There will always be a slight difference between the temperature at the thermocouple and the actual temperature at your sample's location.

Calibration is the act of acknowledging this gap. It requires placing a calibrated probe where the sample will be and adjusting the controller's offset. It’s an act of intellectual honesty—trusting the system, but verifying its reality.

The Discipline of Patience: Preventing Thermal Shock

Ceramic tubes are strong but brittle. Heating or cooling them too quickly induces immense internal stress, causing them to crack. This phenomenon, known as thermal shock, is a law of physics. Adhering to recommended ramp rates is an exercise in patience that respects the material limits of the equipment.

Your Goal Defines the Furnace

The right furnace is not the one with the most features, but the one whose architecture is perfectly aligned with your research objective.

| Your Primary Goal | Required Furnace Configuration |

|---|---|

| Basic Heat Treatment / Annealing | A standard, single-zone tube furnace |

| Processing Air-Sensitive Materials | A system with vacuum flanges and gas control |

| Ensuring Uniform Powder Reaction | A rotary tube furnace for continuous mixing |

| Depositing High-Quality Thin Films | A dedicated CVD system with mass flow controllers |

Understanding this link between objective and architecture is the first step toward achieving truly repeatable and reliable results. A furnace is not just a purchase; it is a partnership with a piece of precision engineering. At KINTEK, we build that partnership on a foundation of expert R&D and deep customization, ensuring your furnace is not just a tool, but the perfect solution for your specific challenge.

To build the ideal thermal processing environment for your work, Contact Our Experts.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

Related Articles

- The Physics of Control: Mastering the Three-Stage Journey of Heat in a Tube Furnace

- A War Against Chaos: The Elegant Engineering of the Modern Tube Furnace

- The Geometry of Progress: Why the 70mm Tube Furnace is a Laboratory Cornerstone

- The Art of Isolation: Mastering Material Properties with Tube Furnaces

- From Powder to Power: The Physics of Control in a Tube Furnace