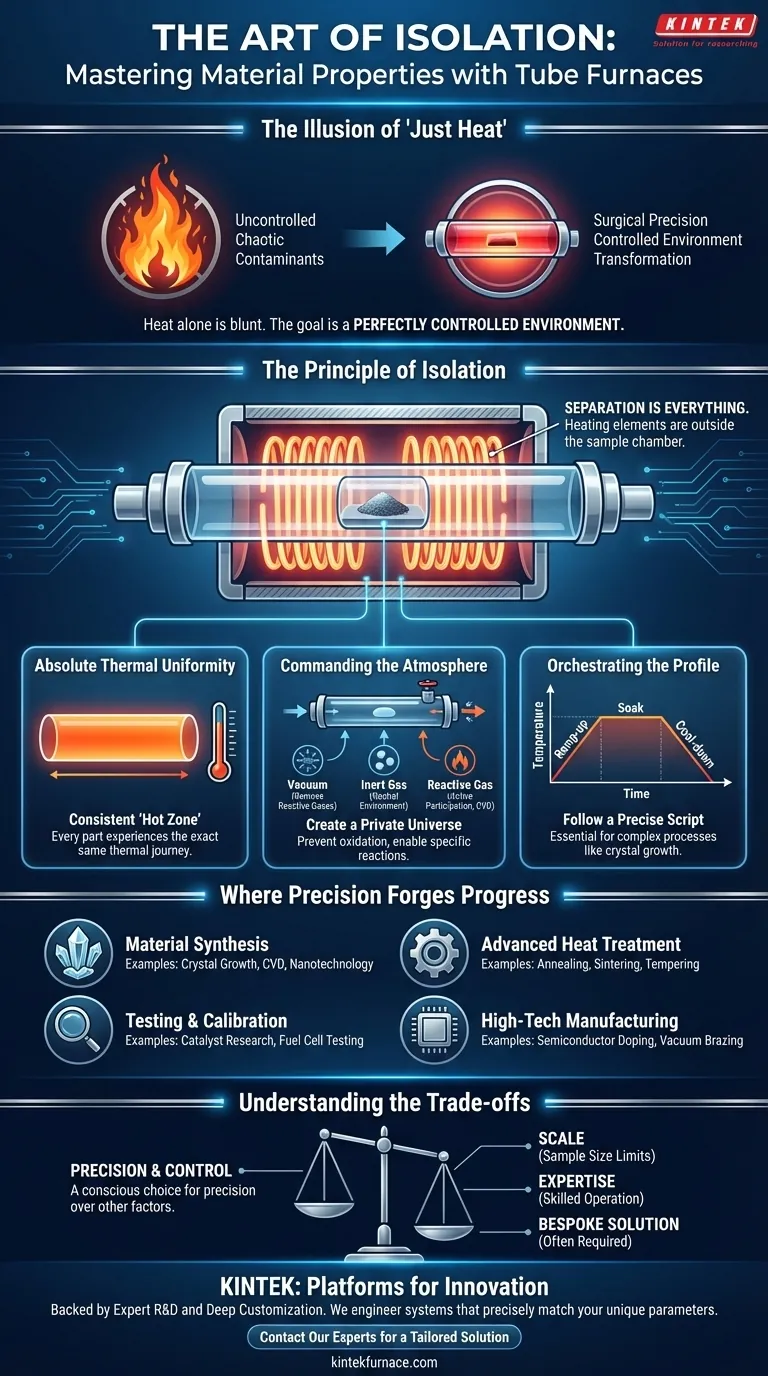

The Illusion of 'Just Heat'

In our minds, a furnace is simple: it makes things hot. We have a deep, instinctual understanding of heat as a raw, powerful force.

But for a materials scientist, a semiconductor engineer, or a researcher developing next-generation battery components, "heat" alone is a blunt instrument. Uncontrolled heat, exposed to the ambient air, is chaotic. The oxygen we breathe becomes a contaminant, the subtle variations in temperature a source of failure.

The real challenge isn't creating heat; it's creating a perfectly controlled environment where heat can perform its work with surgical precision. This is the fundamental problem that the tube furnace was engineered to solve. It's not a tool for heating; it's a tool for controlled transformation.

The Principle of Isolation: How It Works

The genius of the tube furnace lies in its elegant design: the heating elements are separate from the sample. They reside in a cylindrical chamber, wrapping around a process tube that contains the material.

This separation is everything. It transforms a simple heater into a high-fidelity instrument for manipulating matter at a molecular level.

Achieving Absolute Thermal Uniformity

The tubular heating chamber is engineered to radiate energy evenly along its length, creating a "hot zone" of exceptional temperature consistency. Every part of a sample placed within this zone experiences the exact same thermal journey. This uniformity isn't a luxury; it's a prerequisite for creating consistent, reliable materials, whether you're annealing a metal alloy or synthesizing a complex inorganic powder.

Commanding the Atmosphere

By containing the sample within a sealed tube, you gain god-like control over its environment. You can create a private universe for your experiment.

- Create a Vacuum: Evacuate the tube to remove reactive gases like oxygen, preventing oxidation that could compromise the integrity of sensitive metals or ceramics.

- Introduce Inert Gas: Fill the tube with argon or nitrogen to create a completely neutral environment, ensuring the thermal process happens without any unwanted side reactions.

- Use Reactive Gas: Introduce specific gases to actively participate in the process, such as in Chemical Vapor Deposition (CVD), where gases react on a hot surface to form a solid film.

Orchestrating the Temperature Profile

Advanced processes aren't just about reaching a peak temperature. They follow a precise script: a controlled ramp-up, a specific duration at temperature (the "soak"), and a carefully managed cool-down. Tube furnaces excel at executing these complex thermal profiles, which are essential for everything from growing perfect single crystals to tempering steel for optimal toughness.

Where Precision Forges Progress

The combination of uniform heating and atmospheric control makes the tube furnace an indispensable tool in the world's most advanced laboratories and manufacturing facilities. Its applications are a testament to the power of precision.

| Application Category | Key Processes | Impact Area |

|---|---|---|

| Material Synthesis | Crystal Growth, Purification, CVD | R&D, Nanotechnology |

| Advanced Heat Treatment | Annealing, Sintering, Tempering | Metallurgy, Ceramics, Manufacturing |

| Testing & Calibration | Catalyst Research, Fuel Cell Testing, Calibration | Quality Control, Aerospace, Energy |

| High-Tech Manufacturing | Semiconductor Doping, Vacuum Brazing, Curing | Electronics, Medical Devices |

Imagine trying to test a new ceramic for a jet engine turbine blade. The slightest impurity or micro-fracture, introduced by oxidation during heat testing, could lead to catastrophic failure in the field. A tube furnace provides the pristine vacuum environment needed to validate its true performance. This is where control becomes synonymous with safety and reliability.

The Psychologist's Choice: Understanding the Trade-offs

A powerful tool demands a skilled user. The decision to use a tube furnace is a conscious choice for precision over other factors, and understanding its limitations is key to leveraging its strengths.

The Constraints of a Controlled World

The price of perfect control is often scale. The process tube's diameter inherently limits the size of the sample. This makes tube furnaces ideal for research, component manufacturing, and material development, but less practical for heat-treating very large parts, where a box furnace might be more suitable.

The Burden of Expertise

Operating a tube furnace, especially with integrated vacuum systems and gas mixers, requires more technical know-how than a simple oven. It's a professional instrument that rewards a deep understanding of the process.

The Need for a Bespoke Solution

Standard furnace designs are excellent, but groundbreaking research and unique manufacturing challenges often don't fit a standard box. The process tubes, made of quartz or alumina, can be fragile and may require specific dimensions, ports, or configurations. This is where the line between a product and a solution becomes clear. The most critical work demands an instrument tailored to the task.

At KINTEK, we build upon this principle. Backed by expert R&D and in-house manufacturing, we see our furnaces not as off-the-shelf products, but as platforms for innovation. Our deep customization capabilities allow us to engineer Muffle, Tube, Vacuum, and CVD systems that precisely match the unique parameters of your work, ensuring your equipment is a solution, not a limitation.

Whether you are pushing the boundaries of materials science or optimizing a critical production step, having the right tool is paramount. Contact Our Experts

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

Related Articles

- Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

- The Unsung Hero of the Lab: The Deliberate Design of the Single-Zone Split Tube Furnace

- Beyond Heat: The Unseen Power of Environmental Control in Tube Furnaces

- The Geometry of Progress: Why the 70mm Tube Furnace is a Laboratory Cornerstone

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube