Rotary Furnace

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

Item Number : KT-RTF

Price varies based on specs and customizations

- Max. temperature

- 1200℃~1600℃

- Furnace tube material

- High purity quartz / 310S Stainless Steel / Al2O3 / Si3N4

- Temperature control accuracy

- ±1℃

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introducing the KINTEK Laboratory Rotary Furnace: Precision, Versatility, and Customization

The KINTEK Laboratory Rotary Furnace is engineered for superior performance in demanding laboratory environments. Designed with advanced features and built with high-quality materials, this furnace offers unparalleled precision for calcination, drying, sintering, and various heat treatment processes. Our commitment to R&D ensures continuous innovation, allowing us to tailor solutions to your specific research needs.

Ready to enhance your laboratory's capabilities? Discuss your requirements with our furnace experts today.

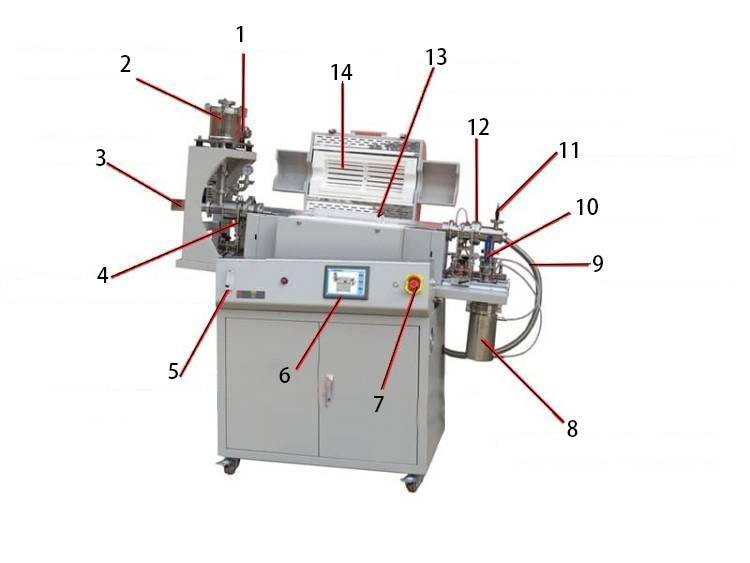

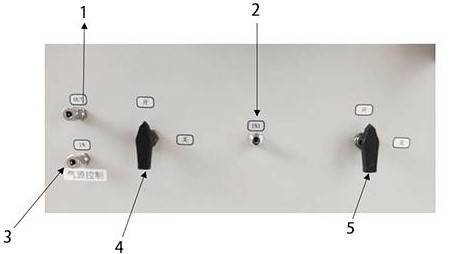

Explore the Details: Design & Components

Our Laboratory Rotary Furnaces are meticulously designed for optimal performance, ease of use, and durability. Below are some visual highlights of its construction and key components:

Control panel and furnace chamber detail. Components include: 1.Electric contact; 2.Level gauge; 3.Feed tank; 4.Pressure gauge; 5.Power button; 6.Control cabinet.

Gas flow system details: 1-2.Flow meter inlet; 3.Gas source; 4.Feed tank inlet ball valve; 5.Furnace tube inlet ball valve.

Versatile Applications: Meeting Diverse Experimental Needs

The KINTEK Laboratory Rotary Furnace is an ideal solution for a wide range of laboratory tasks, particularly for the calcination and drying of materials. It excels with:

- Battery Materials: Processing positive and negative electrode materials for lithium-ion batteries, such as aluminum ferric phosphate, lithium manganate, lithium cobalate, ternary compounds, and graphite cathodes.

- Advanced Materials Processing: Suitable for high-temperature reactions, heat treatment, carbonization, sintering, and high-temperature pyrolysis of rare earth materials, chemical catalytic materials, magnetic materials, powder metallurgy materials, nonferrous metal materials.

- Mineral Processing: Ideal for powder or granular materials of kaolin non-metallic mineral materials.

This equipment is professionally designed for laboratory calcining and drying of non-strong acid-base powder materials and granular materials. Users can choose to operate under vacuum or a controlled atmosphere, depending on the specific material and process requirements.

Do you have a unique application? Contact us to explore a customized furnace solution.

Key Features & Advantages: Engineered for Performance & Reliability

Our Laboratory Rotary Furnace incorporates advanced features derived from our extensive R&D and manufacturing expertise, ensuring optimal results for your experiments:

- Enhanced Design Over Standard Tube Furnaces: Building upon the foundation of a traditional tube furnace, our rotary model includes integrated furnace tube rotation and tilting capabilities. The rotation speed is steplessly regulated, and the tilting angle is adjustable to optimize material processing.

- Uniform Heating: To prevent material hardening and ensure even heating in smooth tubes, options like internal lifting plates or a middle "big belly" type furnace tube can be incorporated through our customization services.

- Vacuum and Controlled Atmosphere: Thanks to KINTEK's excellent sealing technology, the rotary tube furnace can reliably operate under both vacuum and controlled atmosphere environments.

- Superior Materials & Construction:

- The furnace tube is typically made of 310S heat-resistant stainless steel or other materials based on application requirements.

- The furnace chamber utilizes vacuum-formed alumina ceramic fiber material, ensuring high-temperature stability without powdering, low heat capacity, strong firepower, fast heating speed, and uniform temperature field distribution.

- Intelligent Control System:

- Features PLC centralized control with a user-friendly 7-inch TFT touch screen for real-time data display and intuitive operation.

- PID intelligent thermal control ensures accurate heating and excellent thermal uniformity (±1℃).

- Sintering process curve setting: dynamic display of setting curves, multiple process curves can be pre-stored, and each curve can be freely set.

- Scheduled sintering allows for unattended operation.

- Real-time display and recording of sintering power, voltage, and other data, which can be exported for paperless record-keeping.

- Remote control capabilities allow for real-time observation of equipment status.

- Temperature correction features allow for nonlinear correction throughout the sintering process, bridging the difference between main control temperature and sample temperature.

- Operational Efficiency & Safety:

- Equipped with an alarm function for unattended sintering.

- Includes a material level monitor and a vibrator to facilitate better material introduction and monitoring.

- High-purity Al2O3 fiber refractory insulation material provides excellent insulation, effectively reducing power consumption.

- Advanced and stable dynamic sealing system ensures operational integrity under vacuum and atmosphere.

- The furnace body can be tilted (e.g., from -14° for discharging to +2° for feeding) for convenient loading and unloading.

- Air outlet flaring design helps to avoid blockages.

- Durable Components: Utilizes robust heating elements like Mo-doped Fe-Cr-Al alloy, SiC, or MoSi2 depending on the temperature requirements.

- Customization: We offer a whole variety of custom design options to build an exclusive rotary tube furnace perfectly suited for your research job.

Interested in these advanced features? Request a detailed proposal tailored to your needs.

Technical Specifications

| Furnace model | KT-RTF12 | KT-RTF14 | KT-RTF16 |

| Max. temperature | 1200℃ | 1400℃ | 1600℃ |

| Constant work temperature | 1100℃ | 1300℃ | 1500℃ |

| Heating rate | 0-20℃/min | 0-10℃/min | |

| Furnace tube material | High purity quartz / 310S Stainless Steel | Al2O3 / Si3N4 / 310S Stainless Steel | |

| Rotary speed | 0-20rpm (Steplessly adjustable) | ||

| Tilting angle | -5 to +30 degrees (Adjustable, typical range, can be customized) | ||

| Furnace tube diameter (mm) | 30 / 40 / 60 / 80 / 100 / 120 / 150 / 230 / 280 (Customizable) | ||

| Single heating zone length (mm) | 300 / 450 / 600 / 800 (Customizable) | ||

| Vacuum sealing solution | SS 304 flange with O-ring / Advanced dynamic sealing system | ||

| Chamber material | High-purity alumina fiber (e.g., Japan Mitsubishi fiber) | ||

| Heating element | Cr2Al2Mo2 wire coil (Fe-Cr-Al alloy doped with Mo) | SiC (Silicon Carbide) | MoSi2 (Molybdenum Disilicide) |

| Temperature sensor | K type | S type | B type |

| Temperature controller | Digital PID controller / Touch screen PID controller (with PLC) | ||

| Temperature control accuracy | ±1℃ | ||

| Electric power supply | AC110-220V (selectable), 50/60HZ, Single Phase / Three Phase (as per requirement) | ||

| Different tube materials, sizes, heating zone lengths, and other specifications can be customized to meet your specific experimental requirements. | |||

Safety & Operational Guidelines

- When the furnace temperature of the equipment is ≥300°C, it is forbidden to open the furnace to avoid injury.

- When the equipment is in use, the reading of the absolute pressure gauge should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure.

- When used under vacuum, the operating temperature of the equipment shall generally not exceed 800°C for quartz tubes, and higher for metallic or ceramic tubes (please consult specifications for your specific tube material). For example, for some operations, vacuum use might be limited to 600°C to ensure longevity and safety depending on the setup. Always refer to the specific model's manual.

Partner with KINTEK for Your Custom Furnace Needs

At KINTEK, we understand that every research project is unique. Our strong deep customization capability allows us to work closely with you to design and manufacture a laboratory rotary furnace that precisely meets your experimental requirements. From specific materials and dimensions to advanced control features, we are dedicated to providing you with a solution that enhances your research outcomes.

Ready to advance your research with a KINTEK furnace? Get in touch with our experts to discuss your project or request a quote today!

Trusted by Industry Leaders

FAQ

What Are The Main Applications Of A Rotary Tube Furnace?

What Is The Principle Of A Rotary Furnace?

What Is A Rotating Furnace Used For?

What Is A Tube Furnace And How Does It Work?

What Are The Main Applications Of Multi-zone Tube Furnaces?

What Are The Main Applications Of A Vacuum Furnace?

What Is An Atmosphere Furnace Used For?

What Are The Common Applications Of A Split Tube Furnace?

What Is A Vertical Tube Furnace?

What Are The Key Features Of A Rotary Tube Furnace?

What Are The Advantages Of Using A Rotary Furnace?

What Are The Main Types Of Rotating Furnaces Available?

What Are The Main Applications Of Tube Furnaces?

What Are The Key Features Of Multi-zone Tube Furnaces?

What Are The Key Features Of A Vacuum Furnace?

What Are The Key Features Of An Atmosphere Furnace?

What Are The Key Features Of A Split Tube Furnace?

What Are The Applications Of A Vertical Tube Furnace?

How Does A Rotary Tube Furnace Work?

What Are The Key Features Of A Rotary Furnace?

How Does A Rotating Furnace Work?

What Are The Advantages Of Using A Tube Furnace?

How Does A Multi-zone Tube Furnace Work?

How Does A Vacuum Furnace Work?

How Does An Atmosphere Furnace Work?

How Does A Split Tube Furnace Work?

What Are The Advantages Of A Vertical Tube Furnace?

What Are The Advantages Of Using A Rotary Tube Furnace?

What Are The Common Applications Of A Rotary Furnace?

What Are The Advantages Of Using A Rotating Furnace?

What Types Of Tube Furnaces Are Available?

What Are The Advantages Of Using A Multi-zone Tube Furnace?

What Are The Advantages Of Using A Vacuum Furnace?

What Are The Advantages Of Using An Atmosphere Furnace?

What Are The Advantages Of Using A Split Tube Furnace?

How Does A Vertical Tube Furnace Work?

What Temperature Can A Rotary Tube Furnace Reach?

How Does A Rotary Furnace Handle Different Materials?

What Safety Features Are Included In Rotating Furnaces?

What Temperature Ranges Can Tube Furnaces Achieve?

What Types Of Multi-zone Tube Furnaces Are Available?

What Types Of Materials Can Be Processed In A Vacuum Furnace?

What Types Of Gases Can Be Used In An Atmosphere Furnace?

What Temperature Can A Split Tube Furnace Reach?

What Types Of Vertical Tube Furnaces Are Available?

What Types Of Materials Can Be Processed In A Rotary Tube Furnace?

Can Rotating Furnaces Be Customized For Specific Applications?

Can Tube Furnaces Operate Under Different Atmospheres?

What Is The Difference Between Hot Wall And Cold Wall Vacuum Furnaces?

What Safety Features Are Available In Advanced Atmosphere Furnaces?

Why Is The Split Design Beneficial In A Tube Furnace?

Why Choose A Vertical Tube Furnace Over A Horizontal One?

What Makes KINTEK Tube Furnaces Special?

Can Vacuum Furnaces Be Customized For Specific Applications?

What Temperature Ranges Can Vertical Tube Furnaces Achieve?

Are Vertical Tube Furnaces Customizable?

4.8 / 5

Incredible precision and durability! This furnace has transformed our lab work.

4.9 / 5

Fast delivery and top-notch quality. Worth every penny!

4.7 / 5

The tilt feature is a game-changer. So easy to use and efficient.

4.9 / 5

Advanced technology meets reliability. Perfect for high-temperature experiments.

4.8 / 5

Superb build quality and consistent performance. Highly recommended!

4.7 / 5

Impressive vacuum efficiency. Delivered faster than expected!

4.9 / 5

A fantastic investment for any lab. The rotary function is brilliant.

4.8 / 5

Exceptional value for money. The precision is unmatched.

4.7 / 5

Durable and technologically advanced. Exceeded all expectations.

4.9 / 5

Perfect for complex experiments. The tilt mechanism is a lifesaver.

4.8 / 5

Reliable and efficient. The best furnace we've ever used.

4.7 / 5

High-quality materials and flawless performance. A must-have!

4.9 / 5

Innovative design with outstanding results. Delivered in record time.

4.8 / 5

The vacuum seal is impeccable. Perfect for sensitive materials.

4.7 / 5

User-friendly and highly durable. A fantastic addition to our lab.

4.9 / 5

Cutting-edge technology with robust construction. Exceeds all standards.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

KINTEK Multi-Zone Tube Furnace: Precise 1700℃ heating with 1-10 zones for advanced material research. Customizable, vacuum-ready, and safety-certified.

Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Precision rotary tube furnace for continuous vacuum processing. Ideal for calcination, sintering, and heat treatment. Customizable up to 1600℃.

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

Advanced PECVD Tube Furnace for precise thin film deposition. Uniform heating, RF plasma source, customizable gas control. Ideal for semiconductor research.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

KINTEK's Rotary Biomass Pyrolysis Furnace converts biomass to biochar, bio-oil, and syngas efficiently. Customizable for research or production. Get your solution now!

1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision high-temperature processing up to 2000°C for labs. Ideal for material synthesis, CVD, and sintering. Customizable options available.

Vertical Laboratory Quartz Tube Furnace Tubular Furnace

Precision KINTEK Vertical Tube Furnace: 1800℃ heating, PID control, customizable for labs. Ideal for CVD, crystal growth & materials testing.

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

1200℃ Muffle Oven Furnace for Laboratory

KINTEK KT-12M Muffle Furnace: Precision 1200°C heating with PID control. Ideal for labs needing rapid, uniform heat. Explore models & customization options.

1400℃ Muffle Oven Furnace for Laboratory

KT-14M Muffle Furnace: Precision 1400°C heating with SiC elements, PID control, and energy-efficient design. Ideal for labs.

1800℃ High Temperature Muffle Oven Furnace for Laboratory

KINTEK Muffle Furnaces: Precision 1800°C heating for labs. Energy-efficient, customizable, with PID control. Ideal for sintering, annealing, and research.

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

Related Articles

Why Your Crystal Growth Experiments Are Failing: The Hidden Culprit in Your Tube Furnace

Struggling with inconsistent CVT results? Discover why your tube furnace's temperature gradient, not your chemistry, is the likely culprit and how to fix it.

More Than a Dial: The Psychology of Precision in Tube Furnace Control

Choosing a tube furnace control system is a strategic decision that shapes process repeatability, data integrity, and research credibility.

A War Against Chaos: The Elegant Engineering of the Modern Tube Furnace

A furnace isn't just a heater; it's a system that battles entropy. Explore the physics of converting electricity to precise, uniform thermal energy.

Mastering the Micro-Environment: The Art and Science of the Laboratory Tube Furnace

Explore how laboratory tube furnaces master thermal processing by controlling temperature, atmosphere, and geometry for advanced material synthesis.

The Material Science of Heat: Choosing a Tube Furnace Beyond Maximum Temperature

Choosing a lab furnace isn't about the highest temperature. It's about matching heating elements, uniformity, and atmosphere to your process for reliable results.

The Art of Isolation: Mastering Material Properties with Tube Furnaces

Tube furnaces excel not by merely heating, but by isolating samples in a controlled atmosphere, enabling precise thermal processing for advanced materials.

Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

Struggling with inconsistent results from your tube furnace? Discover why standard equipment fails and how a modular, customizable approach is key to success.

The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

Vacuum furnaces aren't just for preventing rust; they create a controlled void to achieve unparalleled material purity, properties, and consistency.

The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

Discover how vacuum furnaces eliminate atmospheric contamination to achieve superior material quality, consistency, and throughput in modern manufacturing.

The Unseen Strength: How Vacuum Furnaces Forge Perfect, Stress-Free Joints

Discover how vacuum brazing creates strong, clean, distortion-free joints by eliminating oxidation and mastering thermal stress in a controlled furnace.

Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

Discover the hidden reason your high-temperature experiments fail. It's not your process; it's a material mismatch inside your furnace. Learn how to fix it.

The Geometry of Control: Why Tube Furnaces Define Modern Materials

Tube furnaces are more than ovens; they create the controlled environments essential for innovation in semiconductors, batteries, and new materials.