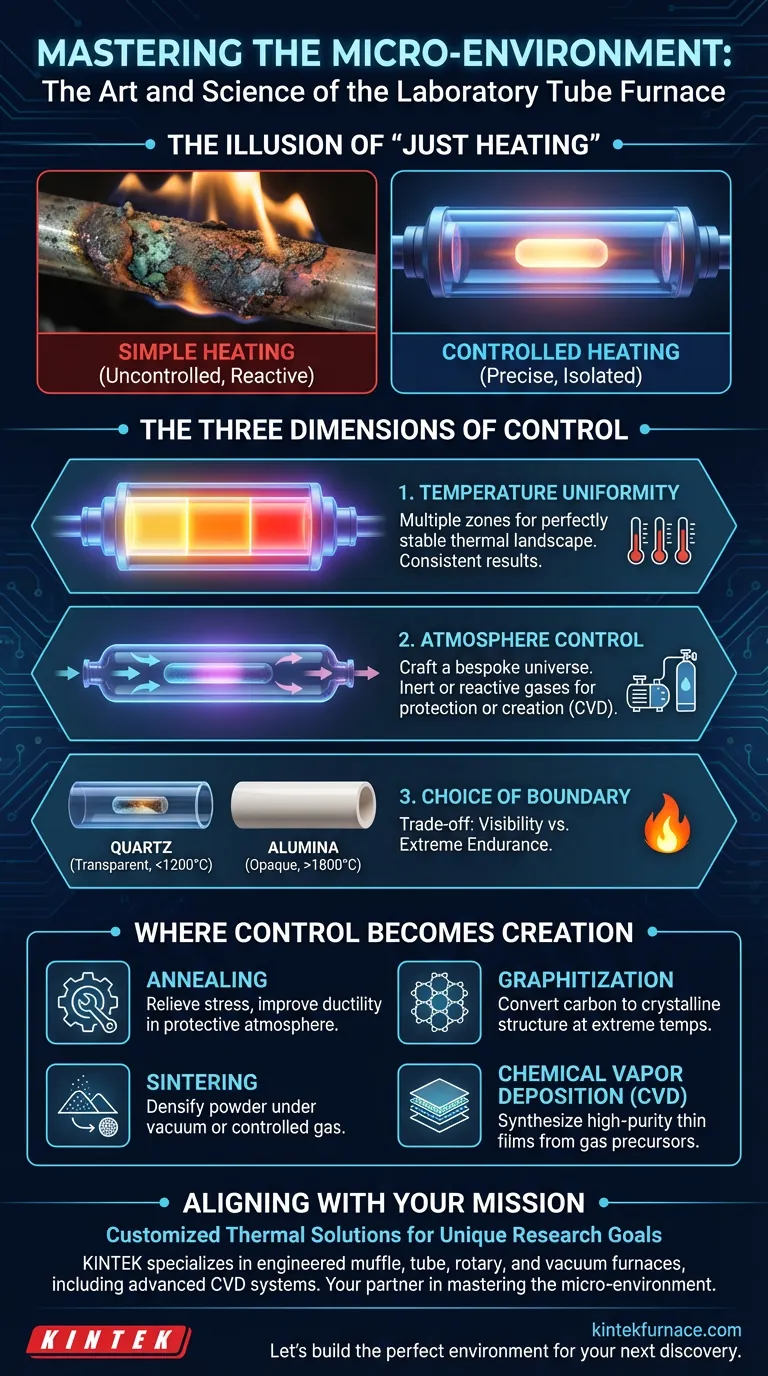

The Illusion of "Just Heating"

At first glance, heating a material seems simple. You apply energy, and its temperature rises. But in the world of materials science, this is a dangerous oversimplification.

As temperatures climb, materials become reactive. The air we breathe—a seemingly benign mix of nitrogen, oxygen, and water vapor—transforms into a corrosive agent, eager to oxidize and contaminate your pristine sample.

This is the fundamental challenge: at the temperatures where new materials are born and properties are perfected, the environment itself becomes the enemy. The goal isn't just to get something hot; it's to control the tiny, isolated universe in which it gets hot.

This is the domain of the laboratory tube furnace.

The Three Dimensions of Control

A tube furnace's power lies not in its heat, but in its absolute authority over the conditions of that heat. This authority is exercised across three critical dimensions.

1. The Dimension of Temperature: Seeking Uniformity

Imagine forging a blade where one part is perfectly tempered while another remains brittle. This is the result of non-uniform heating.

For a material scientist, temperature non-uniformity means inconsistent results and failed experiments. A superior tube furnace addresses this with multiple, independently controlled heating zones. This isn't just about reaching a target temperature; it's about ensuring every single part of the sample experiences that exact temperature, creating a perfectly stable and predictable thermal landscape.

2. The Dimension of Atmosphere: Crafting a Bespoke Universe

The furnace's sealed tube is its defining feature. It allows you to evict the ambient air and replace it with a custom-designed atmosphere. This is where the real magic happens.

You can create a protective shield, bathing the sample in inert gases like argon or nitrogen to prevent any unwanted chemical reactions. It's the equivalent of placing your work in a vault, safe from the outside world.

Or, you can go on the offensive. By introducing specific reactive gases, the furnace becomes a tool for creation. This is the principle behind Chemical Vapor Deposition (CVD), where gases decompose on a heated substrate to build a new material, one atomic layer at a time. You are not just modifying; you are building from scratch.

3. The Dimension of Boundary: The Choice of Vessel

The tube itself is a critical choice. It's the physical boundary between your controlled micro-environment and the furnace's heating elements.

- Quartz: Transparent and ideal for processes under 1200°C. It allows you to see your sample—a small but significant psychological comfort—but it has its thermal limits.

- Alumina: An opaque ceramic that can withstand extreme temperatures (up to 1800°C). It's the choice for high-temperature synthesis and processes that demand chemical robustness.

This decision reflects a fundamental trade-off between visibility and endurance, a choice dictated entirely by the ambition of the experiment.

Where Control Becomes Creation

When these dimensions of control are mastered, a tube furnace transforms from a simple oven into an engine of innovation.

| Application | Core Objective | The Role of the Furnace |

|---|---|---|

| Annealing | Relieve internal stress, improve ductility | Provide a perfectly uniform heat soak in a protective atmosphere to prevent surface oxidation. |

| Graphitization | Convert carbon to a crystalline structure | Deliver extreme, stable temperatures in an inert environment to drive precise structural change. |

| Sintering | Densify a powder into a solid object | Heat particles to their bonding point under vacuum or a controlled gas to ensure purity. |

| Chemical Vapor Deposition (CVD) | Synthesize a high-purity thin film | Act as a reactor, providing the thermal energy and controlled environment for precursor gases to build a new material. |

Each of these processes is a testament to the idea that true material advancement comes not from brute force, but from precise, multi-faceted control.

Aligning the Machine with the Mission

Because every research goal is unique, the ideal furnace cannot be a one-size-fits-all device. The configuration must match the mission.

- Is your goal deposition? You need a CVD system with precise gas flow control.

- Is your goal property modification? You must prioritize exceptional temperature uniformity for processes like annealing.

- Is your goal high-purity synthesis? A vertical furnace orientation might be necessary to avoid sample contact with the tube walls.

The choice of a furnace is a declaration of intent. It reflects an understanding that the instrument is not just a tool, but a partner in the research process. It requires a solution built not just with expert manufacturing, but with a deep R&D understanding of the challenges you face.

At KINTEK, we specialize in translating unique experimental requirements into precisely engineered thermal solutions. Our extensive line of muffle, tube, rotary, and vacuum furnaces, including advanced CVD systems, is built upon a foundation of deep customization. We understand that your work depends on mastering the micro-environment.

Let's build the perfect environment for your next discovery. Contact Our Experts

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

Related Articles

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube

- A War Against Chaos: The Elegant Engineering of the Modern Tube Furnace

- The Geometry of Progress: Why the 70mm Tube Furnace is a Laboratory Cornerstone

- Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

- Beyond Heat: The Unseen Power of Environmental Control in Tube Furnaces