The Illusion of Simplicity

We tend to think of a furnace as a simple tool: a hot box. Its job is to apply heat.

But for the scientists and engineers developing the next generation of materials, this view is a recipe for failure. The real challenge isn't just achieving a high temperature; it's controlling every other variable that heat interacts with. It’s about creating a perfect, predictable universe on a very small scale.

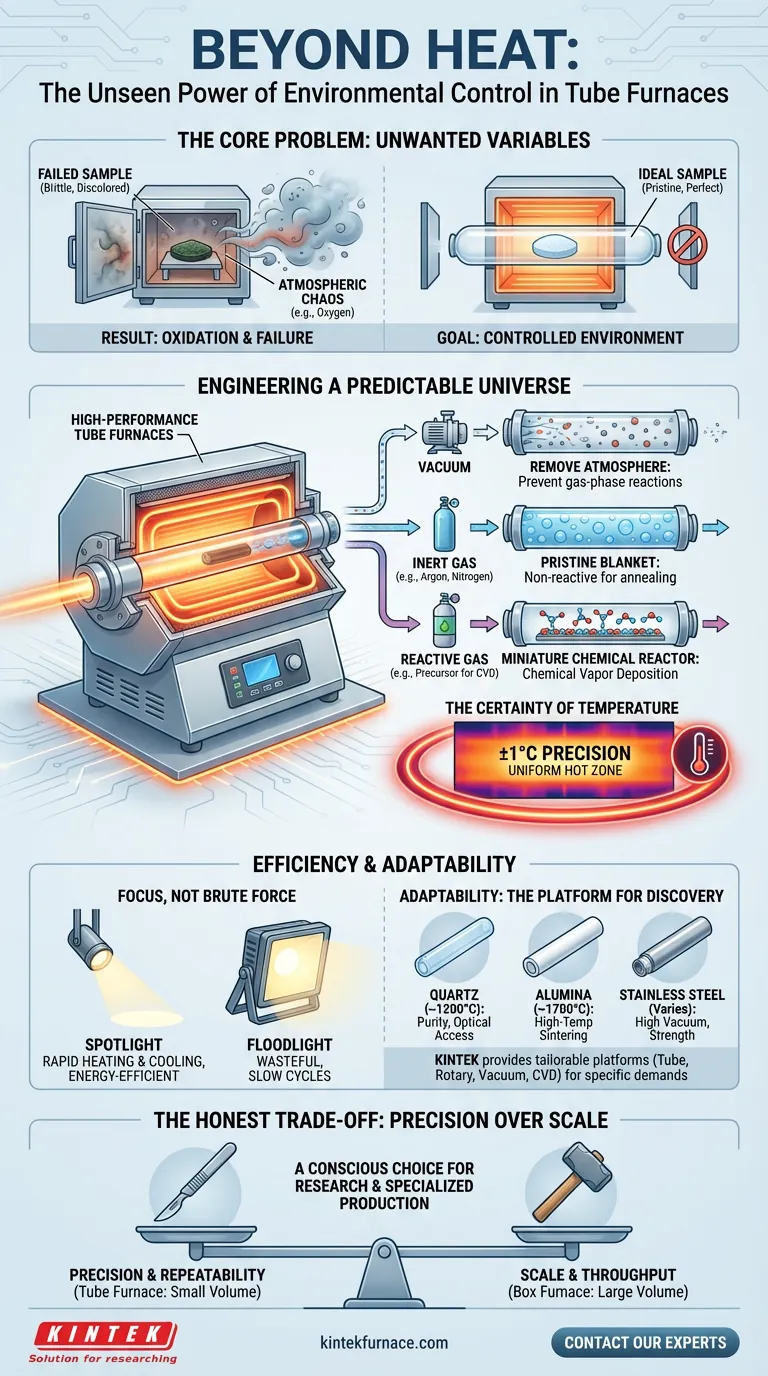

The Core Problem: Unwanted Variables

Imagine a researcher developing a new alloy. They've spent months on theoretical calculations. The material is synthesized, placed in a furnace, and heated to 1000°C.

It comes out brittle and discolored. The experiment failed.

The temperature was correct, but an unseen variable—the oxygen in the air—intervened, causing oxidation and ruining the sample. The failure wasn't in the science, but in the environment. This is the fundamental problem that high-performance tube furnaces are designed to solve.

Engineering a Predictable Universe

A tube furnace's value isn't in its heat, but in its isolation. By containing a sample within a sealed tube, it gives the operator god-like control over the conditions.

Eliminating Atmospheric Chaos

The sealed tube is a barrier to the outside world. This simple design feature allows you to dictate the exact atmosphere your material experiences.

- Vacuum: You can remove the atmosphere entirely, creating a deep vacuum to prevent any unwanted gas-phase reactions.

- Inert Gas: You can flood the chamber with an inert gas like argon or nitrogen, creating a pristine, non-reactive blanket for processes like bright annealing.

- Reactive Gas: You can introduce a specific precursor gas, turning the furnace into a miniature chemical reactor for processes like Chemical Vapor Deposition (CVD).

This isn't just a feature; it's a guarantee that your results are a consequence of your intended inputs, not random atmospheric contamination.

The Certainty of Temperature

Control extends to the heat itself. Unlike a large box furnace where temperatures can vary, a tube furnace's heating elements surround the chamber, creating an exceptionally uniform hot zone.

Achieving a setpoint with a precision of ±1°C is standard. This removes temperature fluctuation as a variable, giving you the psychological confidence that your material was processed under the exact conditions you designed.

Efficiency as a Function of Design

This focus on control leads to profound practical efficiencies.

Focus, Not Brute Force

By heating a small, contained volume, a tube furnace is incredibly energy-efficient. It’s the difference between a spotlight and a floodlight. Energy is directed precisely where it’s needed, enabling rapid heating and cooling cycles that are impossible in larger systems.

This speed is critical for simulating certain real-world phenomena. A specialized vertical drop tube furnace, for instance, is designed to study the rapid combustion of a single particle of coal or biomass as it falls through the hot zone—a process that lasts mere seconds.

Adaptability: The Platform for Discovery

A tube furnace is not a single tool; it's a highly adaptable platform. By simply changing the process tube, you can radically alter its capabilities.

| Tube Material | Max Temperature (Approx.) | Primary Use Case |

|---|---|---|

| Quartz | ~1200°C | Purity, optical access, general inert processes |

| Alumina | ~1700°C | High-temperature sintering, annealing |

| Stainless Steel | Varies | High vacuum integrity, mechanical strength |

This modularity means the same furnace can be used for low-temperature CVD synthesis one day and high-temperature ceramic sintering the next.

When your research demands this level of flexibility, a one-size-fits-all solution falls short. A system designed for deep customization becomes essential. This is where the engineering and manufacturing expertise of a company like KINTEK becomes invaluable, providing advanced, tailorable platforms like Tube, Rotary, Vacuum, and CVD furnaces that are built for the specific demands of your work.

The Honest Trade-Off: Precision Over Scale

Of course, this level of control comes with a trade-off: volume. The diameter of the tube inherently limits the size and throughput of your samples.

But this isn't a flaw; it's a conscious choice. You are choosing the scalpel over the sledgehammer. A tube furnace is the ultimate tool for research, process development, and specialized production where the quality and repeatability of the result are non-negotiable. The investment in such a system is an investment in certainty.

For those whose work depends on creating perfect conditions, the control offered by a tube furnace is the foundation of success.

If your research requires an environment of absolute control and predictability, it's time to build the exact tool for the job. Contact Our Experts

Visual Guide

Related Products

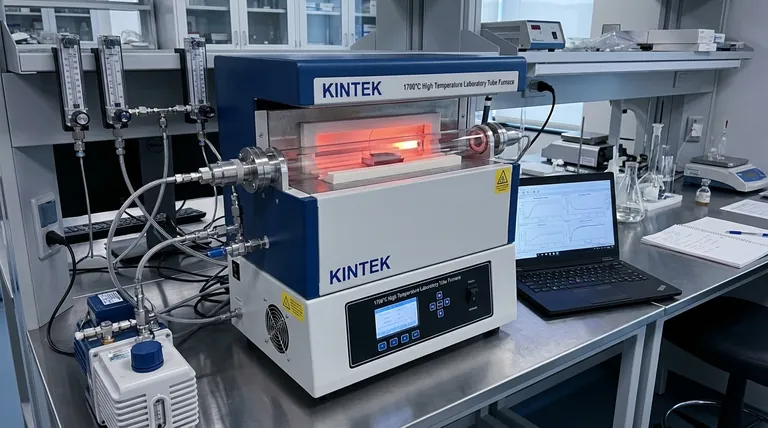

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

Related Articles

- The Unsung Hero of the Lab: The Deliberate Design of the Single-Zone Split Tube Furnace

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube

- The Physics of Control: Mastering the Three-Stage Journey of Heat in a Tube Furnace

- From Powder to Power: The Physics of Control in a Tube Furnace

- The Geometry of Progress: Why the 70mm Tube Furnace is a Laboratory Cornerstone