Muffle Furnace

1400℃ Muffle Oven Furnace for Laboratory

Item Number : KT-14M

Price varies based on specs and customizations

- Max. temperature

- 1400℃

- Constant work temperature

- 1300℃

- Temperature control accuracy

- ±1℃

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

KT-14M Series Muffle Furnace: Precision High-Temperature Performance

The KINTEK KT-14M Muffle Furnace is engineered for demanding laboratory applications, featuring high-quality Japan alumina polycrystalline fiber insulation and robust Silicon Carbide (SiC) heating elements. Achieve precise and uniform temperatures up to 1500°C (constant work temperature 1300°C), controlled by an intelligent PID microprocessor for exceptional accuracy.

For enhanced usability and data management, the KT-14M Pro model comes equipped with a versatile 7-inch TFT smart touch screen controller. This intuitive interface allows operators to easily set, save, and manage multiple heating programs, simplifying complex operations and providing valuable historical data analysis capabilities.

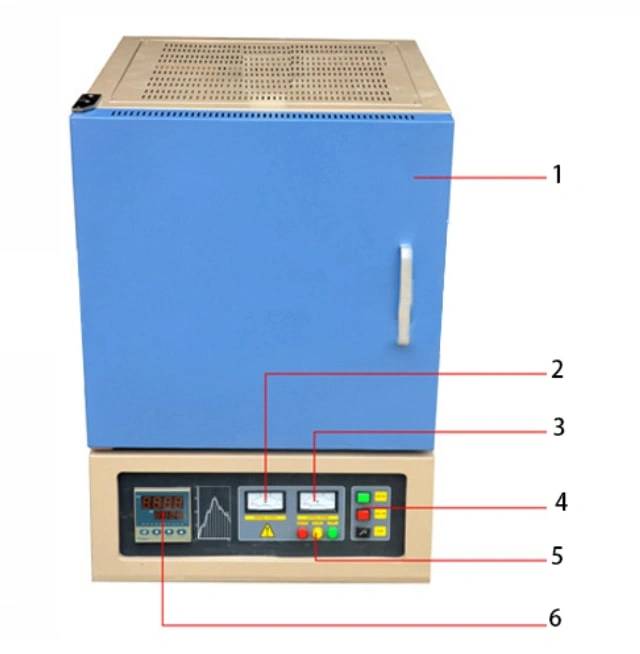

Detail & Parts

Key Features & Advantages

- High-Temperature Capability: Reaches a maximum temperature of 1400°C, with a constant working temperature of 1300°C. Ideal for processes requiring precise high-heat applications.

- Superior Temperature Control & Uniformity: PID intelligent temperature microprocessor ensures high temperature control accuracy (±1℃) and excellent temperature uniformity (±5℃).

- Advanced Insulation & Energy Efficiency: Features high-quality Japan alumina polycrystalline fiber insulation, ensuring minimal heat loss and superior energy saving. The double furnace shell design with forced air cooling maintains a low surface temperature.

- Durable Heating Elements: Utilizes Silicon Carbide (SiC) heating elements, professionally configured to optimize heat radiation properties and ensure a long service life.

- Enhanced User Interface (KT-14M Pro): The Pro model includes a 7-inch TFT smart touch screen controller for more user-friendly program setting, operation, and historical data analysis.

- Robust Safety Features: Equipped with a safety interlock system that shuts off power if the furnace door is opened, or in case of over-temperature or sensor malfunction.

- Efficient and Compact Design: Offers a compact design with a small footprint, making it a versatile addition to any laboratory.

- Contamination-Free Environment: The muffle design isolates materials from direct heat sources, ensuring a clean heating process crucial for sensitive applications.

Technical Specifications

| Furnace model | KT-14M | ||

|---|---|---|---|

| Max. temperature | 1400℃ | ||

| Constant work temperature | 1300℃ | ||

| Chamber material | Japan alumina fiber | ||

| Heating element | Silicon Carbide | ||

| Heating rate | 0-20℃/min | ||

| Temperature sensor | S type thermal couple | ||

| Temperature controller | Digital PID controller/Touch screen PID controller (KT-14M Pro) | ||

| Temperature control accuracy | ±1℃ | ||

| Temperature uniformity | ±5℃ | ||

| Electric power supply | AC110-220V,50/60HZ | ||

| Standard Chamber Sizes Stocks | |||

| Chamber size (mm) | Effective volume (L) | Chamber size (mm) | Effective volume (L) |

| 100x100x100 | 1 | 300x300x400 | 36 |

| 150x150x150 | 3.4 | 400x400x400 | 64 |

| 150x150x200 | 4.5 | 500x500x500 | 125 |

| 200x200x200 | 8 | 600x600x600 | 216 |

| 200x200x300 | 12 | 800x800x800 | 512 |

| Customer design sizes and volume is accepted | |||

Applications

Muffle furnaces are versatile high-temperature heating devices used in various industrial and laboratory settings. They are designed to provide precise temperature control and isolation from combustion contaminants, making them ideal for a range of applications:

- Ashing Samples: Crucial for determining the residue content in organic and inorganic materials.

- Heat Treatment: Essential for processes like annealing, hardening, and tempering of metals and alloys.

- Materials Research: Used to study material behavior at high temperatures and synthesize new materials.

- Melting Glass: Ideal for melting and fusing glass for technical ceramics and enamel coatings.

- Soldering and Brazing: Provides necessary high temperatures for strong and reliable joints.

- Technical Ceramics: Used in the production and testing of technical ceramics requiring precise temperature control.

- Enamel Coatings: Essential for creating durable and aesthetically pleasing enamel coatings.

Comprehensive Safety Systems

- Over-Current and Over-Temperature Protection: The furnace is equipped with over-current protection and over-temperature alarming functions; power will be automatically shut off if thresholds are exceeded.

- Thermal Couple Malfunction Detection: A built-in thermal couple detecting function will stop heating and trigger an alarm if a break or failure is detected.

- Power Failure Restart (KT-14M Pro): The KT-14M Pro model supports a power failure restarting function, allowing the furnace to resume its heating program once power is restored.

Operating Principle

Muffle furnaces operate on the principle of indirect heating. Heating elements located outside a sealed muffle chamber heat the ceramic muffle. This muffle, in turn, radiates heat to the contents inside, ensuring uniform temperature distribution and preventing contamination from the heating elements or combustion byproducts.

Standard Package

| No. | Description | Quantity |

|---|---|---|

| 1 | Furnace | 1 |

| 2 | Thermal block | 1 |

| 3 | Crucible tong | 1 |

| 4 | Heat resistant glove | 1 |

| 5 | Operation manual | 1 |

Customization and Optional Enhancements

KINTEK understands that unique experimental requirements often demand tailored solutions. Beyond our standard configurations, we offer several optional setups for the KT-14M Muffle Furnace:

- Independent furnace temperature monitoring and recording systems.

- RS 485 communication port for PC remote control and data exporting.

- Ports for inert gases, exhaust output, and observation windows.

- Upgrade to the touch screen temperature controller (standard on KT-14M Pro) for versatile, operator-friendly functions.

Our strong deep customization capability allows us to precisely meet your specific needs.

Your Partner in Advanced High-Temperature Solutions: KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Request a Quote or Consultation

Ready to enhance your laboratory with the KT-14M Muffle Furnace? For detailed specifications, custom configurations to meet your unique experimental requirements, or to discuss how this furnace can benefit your research, please reach out to us. Fill out our Contact Form, and a KINTEK specialist will be in touch shortly to assist you.

FAQ

What Are The Main Applications Of A Muffle Furnace?

What Is A Rotating Furnace Used For?

What Are The Key Features Of A Muffle Furnace?

What Are The Main Types Of Rotating Furnaces Available?

How Does A Muffle Furnace Work?

How Does A Rotating Furnace Work?

What Are The Advantages Of Using A Muffle Furnace?

What Are The Advantages Of Using A Rotating Furnace?

What Types Of Muffle Furnaces Are Available?

What Safety Features Are Included In Rotating Furnaces?

Can Rotating Furnaces Be Customized For Specific Applications?

4.8 / 5

This furnace heats up incredibly fast! Perfect for our lab's tight schedules.

4.7 / 5

Solid build and precise temperature control. Worth every penny!

4.9 / 5

Delivered sooner than expected! Performance exceeds our high standards.

4.8 / 5

The durability is impressive. Handles daily use without a hitch.

4.9 / 5

Cutting-edge tech makes complex experiments a breeze. Love it!

4.7 / 5

Reliable and efficient. A fantastic investment for any serious lab.

4.8 / 5

Superb quality! The temperature uniformity is spot-on every time.

4.7 / 5

Easy to operate and maintain. A lab game-changer!

4.9 / 5

Fast shipping and flawless performance. Highly recommend!

4.8 / 5

Robust design meets advanced technology. Exceeds expectations.

4.7 / 5

Consistent results and user-friendly. Perfect for high-temperature applications.

4.9 / 5

Top-notch performance and durability. A must-have for precision work!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory Muffle Oven Furnace with Bottom Lifting

Boost lab efficiency with KT-BL Bottom Lifting Furnace: precise 1600℃ control, superior uniformity, and enhanced productivity for material science and R&D.

1200℃ Muffle Oven Furnace for Laboratory

KINTEK KT-12M Muffle Furnace: Precision 1200°C heating with PID control. Ideal for labs needing rapid, uniform heat. Explore models & customization options.

1800℃ High Temperature Muffle Oven Furnace for Laboratory

KINTEK Muffle Furnaces: Precision 1800°C heating for labs. Energy-efficient, customizable, with PID control. Ideal for sintering, annealing, and research.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Vacuum Induction Melting Furnace

Explore KINTEK's Vacuum Induction Melting Furnace for high-purity metal processing up to 2000℃. Customizable solutions for aerospace, alloys, and more. Contact us today!

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

1700℃ High Temperature Muffle Oven Furnace for Laboratory

KT-17M Muffle Furnace: High-precision 1700°C lab furnace with PID control, energy efficiency, and customizable sizes for industrial & research applications.

Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

KINTEK Mesh Belt Furnace: High-performance controlled atmosphere furnace for sintering, hardening & heat treatment. Customizable, energy-efficient, precise temperature control. Get a quote now!

Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

Discover KINTEK's Hydrogen Atmosphere Furnace for precise sintering & annealing in controlled environments. Up to 1600°C, safety features, customizable.

1700℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-17A Controlled Atmosphere Furnace: Precise 1700°C heating with vacuum & gas control. Ideal for sintering, research & material processing. Explore now!

1400℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-14A Controlled Atmosphere Furnace for labs & industry. 1400°C max temp, vacuum sealing, inert gas control. Customizable solutions available.

1200℃ Controlled Inert Nitrogen Atmosphere Furnace

KINTEK 1200℃ Controlled Atmosphere Furnace: Precision heating with gas control for labs. Ideal for sintering, annealing, and material research. Customizable sizes available.

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

KINTEK's electric rotary furnaces offer precision heating up to 1100°C for calcination, drying, and pyrolysis. Durable, efficient, and customizable for labs and production. Explore models now!

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Reliable CF/KF flange vacuum electrode feedthrough for high-performance vacuum systems. Ensures superior sealing, conductivity & durability. Customizable options available.

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.

Related Articles

Why Your Thermal Processing Fails: The Hidden Mismatch in Your Furnace

Struggling with inconsistent furnace results? Discover the hidden design mismatch sabotaging your experiments and learn how to choose the right furnace for success.

Cracked Crucibles, Inconsistent Data? The Post-Heating Step You're Missing

Stop blaming your furnace for inconsistent results. Discover how the critical post-heating cooling process sabotages your data and how to solve it for good.

Why Your High-Temperature Experiments Fail—And How to Fix Them for Good

Struggling with inconsistent furnace results? Discover the hidden design trade-offs causing failures and learn how to select a furnace engineered for success.

Beyond the Program: Why Your Sintering Fails and How to Guarantee Uniformity

Struggling with cracked or inconsistent parts? Discover why your furnace's thermal environment, not just your program, is the real culprit and how to fix it.

Why Your High-Temperature Synthesis Results Are Unreliable—And How to Fix It

Struggling with inconsistent results in material synthesis, CVD, or annealing? Discover the hidden cause of failure is your furnace's environment, not your process.

Beyond the Checklist: Why Your High-Temperature Furnace Fails (And How to Ensure It Won't)

Frustrated by failed heat treatments despite following safety rules? Discover the hidden physical reasons for failure and how intelligently designed furnaces ensure process reliability.

Gravity and Heat: The Elegant Engineering of the Drop Tube Furnace

Discover how drop tube furnaces leverage gravity and precise thermal control to study materials in freefall, enabling advanced research in combustion and synthesis.

Why Your High-Temperature Furnace Fails: It’s Not the Heating Element, It’s the Physics

Tired of replacing burnt-out furnace heating elements? Discover the hidden thermal physics that causes premature failure and learn how a systems approach ensures reliability.

The Physics of Mismatched Tools: Why a Tube Furnace Isn't for Wastewater

A tube furnace is for precise material synthesis, not bulk water treatment. Understand the physics of heat capacity to choose the right environmental tech.

Mastering the Void: How Tube Furnaces Forge the Atoms of Innovation

Explore how tube furnaces create pristine, controlled environments, essential for the atomic-level precision in semiconductor and battery manufacturing.

The Invisible Saboteur: Why Your High-Temp Furnace Fails (And How to Stop It)

Frustrated by recurring furnace failures and short circuits? Discover the hidden cause—metallic vapor deposition—and learn how a furnace truly designed for your process can end the cycle for good.

The Physics of Perfection: How Vacuum Furnaces Eliminate Metallurgical Uncertainty

Vacuum heat treatment offers more than a clean surface; it provides ultimate control by eliminating atmospheric variables, enhancing material integrity and process repeatability.