You’ve done everything by the book. The material preparation was meticulous, the temperature profile was programmed perfectly, and the process was run exactly like last time. Yet, when you open the furnace door, the results are a frustrating mix: some samples are perfect, others are unusable. You’re left wondering, "What went wrong this time?"

This scenario is all too common in labs and production facilities. It kicks off a costly and time-consuming cycle of troubleshooting that stalls innovation and drives up costs.

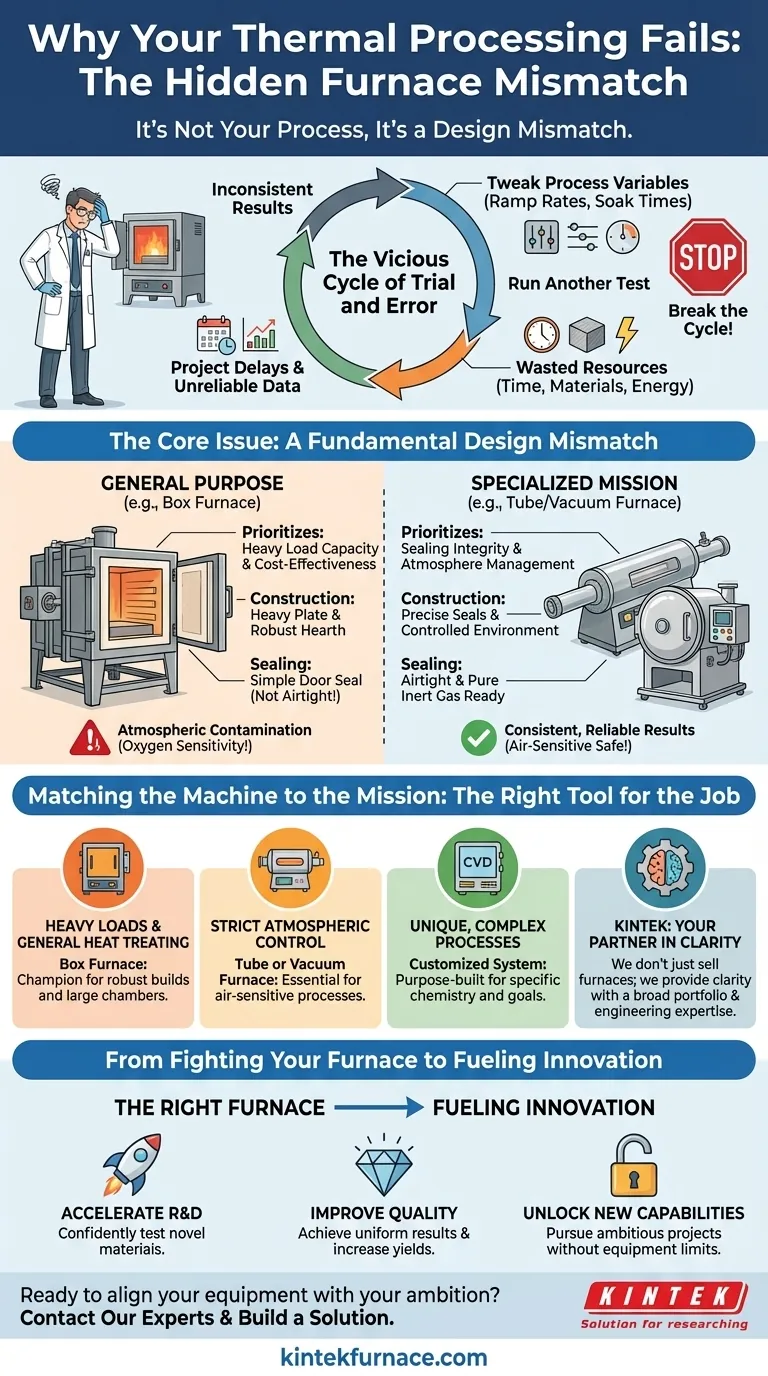

The Vicious Cycle of 'Trial and Error'

When faced with inconsistent outcomes, the natural reaction is to blame the process variables. We tweak the ramp rates, extend the soak times, or meticulously re-calibrate the controllers. We might even question the quality of our raw materials. Each adjustment leads to another test run, consuming more time, more energy, and more valuable materials.

This isn't just a scientific frustration; it's a significant business problem.

- Project Delays: An R&D project that should take weeks can stretch into months, delaying new product launches.

- Wasted Resources: Every failed run scraps expensive materials and consumes significant energy and labor.

- Unreliable Data: Inconsistent results erode confidence in your findings, whether for a peer-reviewed paper or a critical quality control report.

But what if the problem isn't in your process parameters at all? What if the root cause is a fundamental misunderstanding of the tool you're using?

It’s Not Your Process, It’s a Design Mismatch

The common mistake is to think of a furnace as a simple "hot box." As long as it reaches the target temperature, it should work. The reality is that every furnace is a piece of specialized equipment, engineered with specific design trade-offs that make it exceptional for some tasks and entirely unsuitable for others.

The classic example is the Box Furnace.

As a general-purpose workhorse, its design prioritizes two things: heavy load capacity and cost-effectiveness. To achieve this, it's built with heavy plate construction, a robust hearth for massive parts, and a large, simple swing-out or vertical lift door for easy access.

Herein lies the hidden trade-off: its sealing mechanism. To keep costs down and simplify operation, the door seal is straightforward and functional, but it is not designed to be perfectly airtight.

This is the critical detail. If your process involves materials sensitive to oxygen or requires a pure inert gas atmosphere, this "good enough" seal becomes a constant, invisible source of contamination. No amount of process tweaking can overcome this fundamental design limitation. You are trying to achieve a specialized result with a generalized tool. Your "fixes" are treating the symptoms (inconsistent results) while ignoring the disease (an atmospheric mismatch).

Matching the Machine to the Mission

The solution isn't to work harder; it's to select a tool whose core design philosophy matches the non-negotiable requirements of your application. To get repeatable, reliable results, you need a furnace engineered specifically for the challenges you face.

This is where understanding the full spectrum of furnace technology becomes crucial.

- For Heavy Loads & General Heat Treating: The Box Furnace is, and remains, the undisputed champion. Its robust build and large chamber are perfectly matched to the mission.

- For Strict Atmospheric Control: A Tube Furnace or Vacuum & Atmosphere Furnace is the correct choice. Their designs prioritize sealing integrity and atmosphere management above all else, providing the controlled environment that air-sensitive processes demand.

- For Unique, Complex Processes: Sometimes, an off-the-shelf solution doesn't exist. This is where a partner with deep engineering expertise is needed to create a customized system (like a CVD/PECVD unit) that is purpose-built for your specific chemistry and goals.

At KINTEK, we don't just sell furnaces; we provide clarity. Our broad portfolio of Muffle, Tube, Rotary, and Vacuum furnaces exists because we know there is no one-size-fits-all solution. Our in-house manufacturing and R&D teams are obsessed with these fundamental design principles, ensuring the furnace we recommend is the one that will actually solve your problem.

From Fighting Your Furnace to Fueling Innovation

When you finally have the right tool for the job, the entire dynamic of your work changes. The constant struggle against unpredictable results disappears, replaced by the confidence to push boundaries.

Instead of spending weeks troubleshooting, your team can:

- Accelerate R&D: Confidently test novel air-sensitive materials without fear of oxidation.

- Improve Quality: Achieve uniform results batch after batch, drastically increasing production yields.

- Unlock New Capabilities: Pursue more ambitious projects that were previously deemed too risky or difficult due to equipment limitations.

Ultimately, matching the furnace to the mission stops you from fighting your equipment and frees you to focus on innovation.

The right furnace doesn't just get hot—it eliminates critical variables so you can get reliable answers, faster. If you're tired of gambling on your results and are ready to align your equipment with your ambition, our team of experts is here to help analyze the specific demands of your project. Let's build a solution that delivers predictability and performance. Contact Our Experts.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

Related Articles

- Why Your High-Temperature Experiments Fail—And How to Fix Them for Good

- Cracked Crucibles, Inconsistent Data? The Post-Heating Step You're Missing

- Why Your High-Temperature Furnace Fails: It’s Not the Heating Element, It’s the Physics

- Beyond the Program: Why Your Sintering Fails and How to Guarantee Uniformity

- Gravity and Heat: The Elegant Engineering of the Drop Tube Furnace