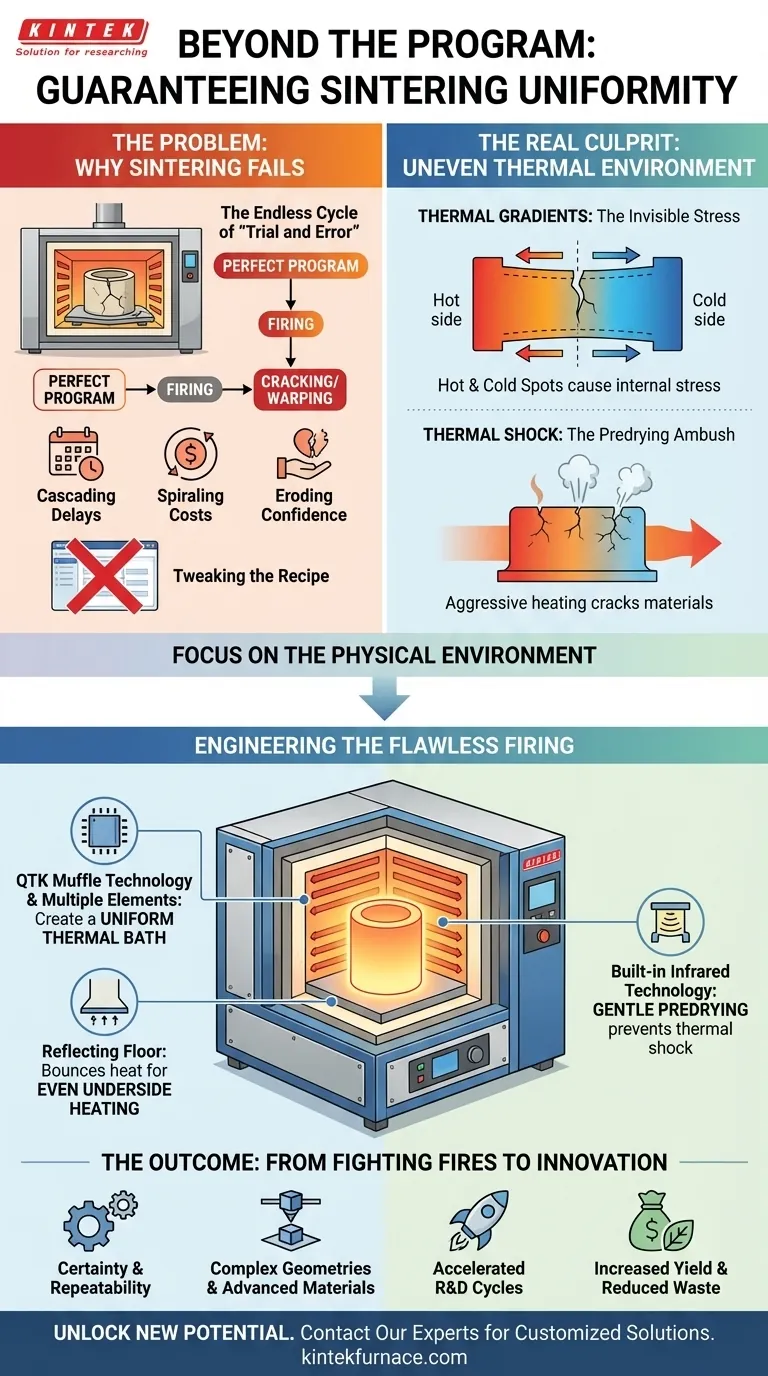

You know the feeling. After a meticulously planned, multi-hour firing cycle, you open the furnace door with anticipation, only to be met with disappointment. A hairline crack spiderwebs across a critical ceramic component. A high-value part has warped just enough to be useless. All that time, energy, and expensive material—wasted. You check the program logs, and everything looks perfect. The temperature ramped exactly as commanded. So, what went wrong?

The Endless Cycle of "Trial and Error"

If this scenario is familiar, you're not alone. In laboratories and production facilities worldwide, this is a chronic source of frustration. The common reaction is to blame the "recipe." Engineers and technicians spend countless hours tweaking the digital firing program: adjusting ramp rates, extending soak times, or lowering peak temperatures, hoping to stumble upon the magic formula.

Each failed attempt is more than just a minor setback. It represents:

- Cascading Project Delays: A single failed run can push timelines back by days or weeks.

- Spiraling Material Costs: Wasting advanced or precious materials directly impacts your budget.

- Eroding Confidence: When results are unpredictable, it becomes impossible to guarantee quality or reliably scale a process. You start questioning your own methods.

This cycle of guesswork is exhausting and expensive. But its biggest flaw is that it’s focused on the wrong problem. You’re trying to solve a hardware problem with a software fix.

The Real Culprit: A War of Temperatures Inside Your Furnace

The hard truth is that your perfectly programmed firing cycle is often being undermined by a chaotic, uneven thermal environment. The temperature displayed on your controller is just one data point, not the reality experienced by your entire component. Inside a standard furnace, a hidden battle is raging.

Thermal Gradients: The Invisible Stress

Imagine your component sitting in the chamber. The heating elements cause one side to get hotter, faster than the other. This temperature difference, or "thermal gradient," creates immense internal stress. One part of the material expands while another lags behind. This invisible tug-of-war is what ultimately leads to warping and cracking. No amount of program tweaking can fix a furnace that fundamentally has hot and cold spots.

Thermal Shock: The Predrying Ambush

The most vulnerable stage for many materials, especially ceramics, is predrying. As the furnace heats up, any moisture must escape gently. However, if the heat is applied too aggressively or unevenly, the rapid temperature change creates a "thermal shock," which is often the root cause of those devastating initial cracks.

The "common solutions" of adjusting software fail because they don't change these physical realities. You're simply telling a flawed system to execute its flawed process differently, hoping for a better outcome.

Engineering the Environment: The Anatomy of a Flawless Firing

To truly solve the problem of inconsistent firing and sintering, you must stop focusing on the program and start focusing on the physical environment where the work happens. You need a furnace that isn't just a hot box, but a precisely engineered thermal system designed to eliminate the root causes of failure.

This is where a deep understanding of thermodynamics informs instrument design. An advanced furnace conquers these challenges with an integrated system of features:

-

To defeat thermal gradients: Technologies like QTK Muffle Technology and strategically placed multiple heating elements work in concert. They don't just blast heat into a chamber; they create a uniform thermal "bath" that surrounds the component. A reflecting floor bounces radiant heat to the underside of the part, ensuring it heats as evenly as the top. The result is a truly homogenous temperature environment, eliminating the internal stresses that cause warping.

-

To prevent thermal shock: Modern furnaces incorporate built-in infrared technology specifically for the predrying phase. Instead of relying on brute-force convective heat, IR gently and evenly warms the component from the inside out, allowing moisture to escape without creating stress, effectively preventing cracks before they can ever form.

This isn't just a collection of features; it's a holistic solution. KINTEK furnaces are designed on this principle—that by perfecting the physical heating environment, we empower your process to be perfectly repeatable. Our designs are the direct answer to the fundamental physics that cause failures.

From Fighting Fires to Fueling Innovation: What's Possible Now?

When you no longer have to constantly troubleshoot failed runs, your entire focus can shift. The energy once spent on damage control is now freed up for true progress.

With a furnace that delivers a guaranteed, uniform thermal environment, you can:

- Move from guesswork to certainty, achieving repeatable, reliable results every single time.

- Confidently work with more complex geometries and sensitive, advanced materials that were previously too risky or difficult to process.

- Drastically accelerate your R&D cycles by eliminating weeks of re-running failed experiments.

- Increase yield and slash material waste, delivering a direct, positive impact to your bottom line.

Ultimately, you can build a reputation for quality and innovation, because your foundational processes are finally stable, predictable, and in your complete control.

Your material challenges are unique, and your furnace solution should be too. Instead of trying to fit your complex process into a standard box, let's discuss how an engineered thermal environment can eliminate your most persistent failures and unlock new potential for your research or production. Contact Our Experts to explore a customized solution built for your specific application.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

Related Articles

- Why Your Thermal Processing Fails: The Hidden Mismatch in Your Furnace

- Why Your High-Temperature Furnace Fails: It’s Not the Heating Element, It’s the Physics

- Gravity and Heat: The Elegant Engineering of the Drop Tube Furnace

- Why Your High-Temperature Synthesis Results Are Unreliable—And How to Fix It

- Why Your High-Temperature Experiments Fail—And How to Fix Them for Good