It’s a dreaded moment for any researcher or engineer: a faint flash, a muffled pop, and the glow from your high-temperature furnace vanishes. The internal temperature begins to plummet, taking a critical experiment or a valuable production batch with it. The diagnosis is all too familiar: another heating element has burned out. Your project timeline is now in jeopardy, and the frustrating cycle is about to begin again.

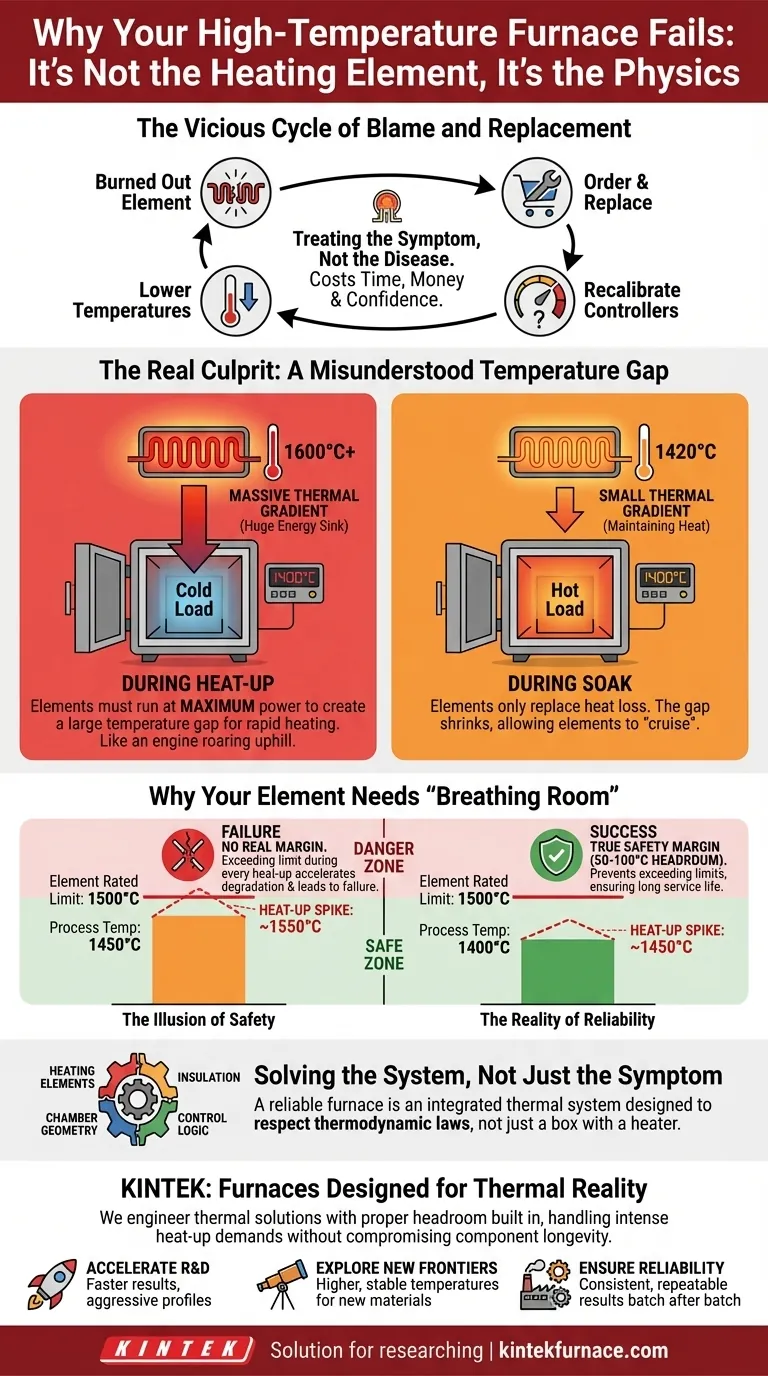

The Vicious Cycle of Blame and Replacement

If this scenario sounds familiar, you are not alone. When a furnace fails, the immediate reaction is often to blame the components. "Did we get a bad batch of heating elements?" you might ask. "Is the temperature controller malfunctioning again?"

This leads to a frustrating and costly loop of troubleshooting:

- Ordering and replacing the expensive elements, hoping the new one lasts longer.

- Recalibrating controllers, spending hours chasing phantom electrical gremlins.

- Conservatively lowering your process temperatures, sacrificing performance to gain a little more uptime.

Each failure doesn't just cost money in replacement parts and technician time. It erodes confidence in your equipment, delays critical research, creates production bottlenecks, and can even force you to abandon ambitious projects that require demanding thermal profiles. You're stuck treating the symptom, while the real disease goes undiagnosed.

The Real Culprit: A Misunderstood Temperature Gap

The reason these common fixes fail is that they ignore a fundamental law of thermodynamics. The problem isn't a faulty component; it's a misunderstanding of how your furnace actually works.

Heat must flow from a hotter region to a colder one.

For your furnace chamber and its workload to reach 1400°C, the heating elements must be significantly hotter than 1400°C. This temperature difference, or "thermal gradient," is the driving force that pushes energy into the chamber.

The size of this gap is not constant; it changes dramatically depending on the heating stage:

- During Heat-Up: When the furnace is cold, it's a massive energy sink. To heat it quickly, the elements must run at maximum power, creating a huge temperature gap—often hundreds of degrees hotter than the current chamber temperature. Think of it like a car engine roaring to climb a steep hill.

- During Soak: Once at the target temperature, the elements only need to replace the heat lost through insulation. The temperature gap shrinks dramatically, and the elements can "cruise" at a temperature only slightly higher than the chamber.

Why Your Element Needs "Breathing Room" to Work

Herein lies the hidden cause of failure. Every heating element has a maximum safe operating temperature. If you choose an element rated for 1500°C to run a process at 1450°C, it seems like you have a 50°C safety margin.

You don't.

To achieve the rapid heat-up required to reach 1450°C, the element might need to temporarily spike to 1550°C. By running your process too close to the element's absolute limit, you force it to exceed that limit during every heat-up cycle. This accelerates degradation and leads to premature, inevitable failure. The "safety margin" was an illusion. A reliable system requires a process temperature that is at least 50-100°C below the element's maximum rating to provide the necessary headroom for the heat-up phase.

Solving the System, Not Just the Symptom

This fundamental principle is where off-the-shelf solutions often fall short and where a system-level engineering approach becomes essential. A truly reliable high-temperature furnace isn't just a well-insulated box with a powerful heater. It's an integrated thermal system designed with this physical reality in mind.

To achieve both high performance and long service life, you need a furnace where the heating elements, insulation, chamber geometry, and control logic are all selected and configured to work in harmony. The solution isn't a "better" element; it's a furnace designed from the ground up to respect the laws of thermodynamics.

KINTEK: Furnaces Designed for Thermal Reality

This is precisely where KINTEK's expertise in R&D and in-house manufacturing makes a critical difference. We don't just sell furnaces; we engineer thermal solutions. Our deep customization capability means we start with your unique process requirements—your target temperatures, your ramp rates, your materials—and design a system that has the proper thermal headroom built in.

Whether it’s one of our Muffle, Tube, or Vacuum Furnaces, we select heating elements and design control strategies that ensure the system can handle the intense demands of the heat-up cycle without ever compromising the longevity of its core components.

From Preventing Failure to Enabling Innovation

When your furnace is no longer a source of constant anxiety, it becomes what it was always meant to be: a tool for discovery. With a properly engineered KINTEK system, you can stop worrying about equipment failure and start pushing the boundaries of what's possible.

- Accelerate R&D: Implement aggressive heating profiles to get results faster, without fear of burnout.

- Explore New Frontiers: Confidently run processes at higher, more stable temperatures to develop next-generation materials.

- Ensure Production Reliability: Achieve consistent, repeatable results batch after batch, ensuring quality and meeting deadlines.

Stop the cycle of costly repairs and unpredictable downtime. It's time to invest in a solution that addresses the root cause of furnace failure. Let us help you design a thermal system that transforms your furnace from a point of failure into a catalyst for discovery. Discuss your unique challenges with our application specialists to see how a furnace built on sound engineering principles can safeguard your process and unlock new potential. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

Related Articles

- Beyond the Checklist: Why Your High-Temperature Furnace Fails (And How to Ensure It Won't)

- The Hidden Saboteur in Your High-Temperature Furnace: Why Your Melts Are Inconsistent—And How to Fix It

- The Invisible Saboteur: Why Your High-Temp Furnace Fails (And How to Stop It)

- Why Your High-Temperature Experiments Fail—And How to Fix Them for Good

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube