It’s a scenario every lab manager dreads. A critical, long-duration heating process is running smoothly. Then, abruptly, it fails. The heating elements have gone cold, the high-value samples are compromised, and the project timeline is shattered. The immediate suspect? A faulty heating element or a power supply glitch. But after a costly replacement and careful restart, it happens again a few weeks later. You’re trapped in a cycle of expensive downtime with no clear cause.

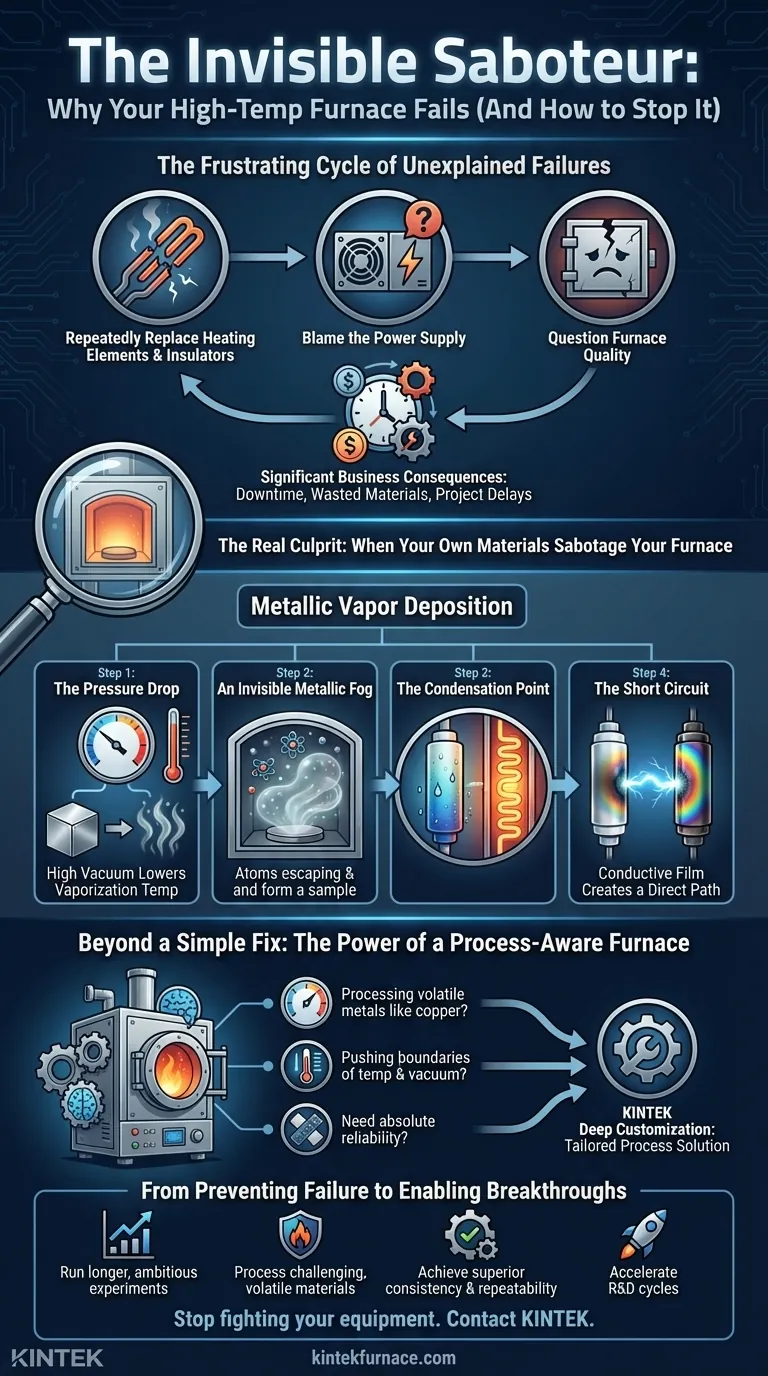

The Frustrating Cycle of Unexplained Failures

This isn't an isolated incident; it's a common and deeply frustrating struggle in materials science and processing. Teams often find themselves troubleshooting the symptoms, not the disease. They might:

- Repeatedly replace heating elements and insulators, treating each failure as a simple case of component wear and tear.

- Blame the power supply, investing time and resources in electrical diagnostics that lead nowhere.

- Question the quality of their furnace, losing confidence in a critical piece of laboratory infrastructure.

Each cycle of failure carries significant business consequences. It’s not just the cost of replacement parts. It’s the hours of lost productivity, the wasted high-purity materials, and the critical project delays that can postpone product launches or invalidate entire research phases. The root of the problem remains hidden, ready to strike again.

The Real Culprit: When Your Own Materials Sabotage Your Furnace

The reason this problem is so difficult to diagnose is that the furnace isn't failing on its own. It's being actively, yet invisibly, sabotaged by the very materials you are processing. The cause isn't a faulty component; it's a fundamental principle of physics that is often overlooked.

The core issue is metallic vapor deposition, driven by an imbalance between your furnace's operating pressure, temperature, and your process load.

From Solid Metal to a Conductive Film: A Four-Step Breakdown

Think of how water vapor condenses on a cold glass on a humid day. A similar, but far more destructive, process is happening inside your furnace.

-

The Pressure Drop: Operating at a high vacuum significantly lowers the temperature at which materials turn from a solid into a gas (vaporization). For metals like copper or chromium, a standard high-temperature, high-vacuum process creates the perfect conditions for them to "boil" off the surface of your parts.

-

An Invisible Metallic Fog: Atoms of metal escape your process load, creating an invisible, metallic vapor that fills the furnace chamber.

-

The Condensation Point: By design, the ceramic insulators that separate your heating elements are slightly cooler than the elements themselves. Just like the cold glass, these cooler surfaces become a perfect condensation point for the hot metallic vapor.

-

The Short Circuit: Over time, this condensed metal builds up into an ultra-thin, conductive film on the insulators. Sometimes it’s visible as a tell-tale "rainbow sheen" or a blackish discoloration. This metallic coating effectively turns a non-conductive insulator into a wire, creating a direct path for electricity—a short circuit that leads to catastrophic failure.

This is why simply replacing the insulators is a temporary fix. You are placing a fresh component into the exact same hostile environment that destroyed the last one. You haven't solved the problem; you've only reset the clock on the next failure.

Beyond a Simple Fix: The Power of a Process-Aware Furnace

To permanently defeat this invisible saboteur, you don't need a stronger insulator; you need a smarter furnace environment—one engineered with a deep understanding of your specific process. The solution lies in creating a system where the temperature, pressure, and materials exist in harmony, not in conflict.

This is where furnace design moves from generic hardware to a tailored process solution. At KINTEK, our approach is built on this principle. We recognize that a furnace is not just a box that gets hot. It is a precisely controlled environment.

Our deep customization capability is the key. Instead of selling you a standard model and hoping it works, our engineers start with your materials and process goals.

- Processing volatile metals like copper? We design a vacuum and atmosphere system that maintains the highest possible pressure your process allows, actively suppressing vaporization and protecting your insulators.

- Pushing the boundaries of temperature and vacuum? We select and position components to minimize temperature differentials and eliminate condensation points.

- Need absolute reliability? We build a furnace—from the chamber materials to the control logic—that is precisely matched to the chemical and physical properties of your load. Our Vacuum & Atmosphere Furnaces and CVD/PECVD Systems are not just products; they are outcomes of this problem-solving philosophy.

From Preventing Failure to Enabling Breakthroughs

When you stop fighting your equipment, you can finally focus on your true objectives. A furnace designed to prevent this fundamental failure mode doesn't just increase uptime; it unlocks new potential.

Suddenly, you can:

- Run longer, more ambitious experiments with confidence, knowing your equipment is stable.

- Process challenging, volatile materials that were previously considered too risky for your equipment.

- Achieve superior process consistency and repeatability, leading to higher-quality results and higher production yields.

- Accelerate your R&D cycles by eliminating weeks of downtime and failed runs from your project plans.

This principle of matching the furnace to the process extends beyond preventing short circuits; it's the foundation of reliable and innovative thermal processing. If you are tired of unexplained failures and want to build a process you can trust, our team is ready to help you design an environment where your work can thrive. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

Related Articles

- Beyond the Program: Why Your Sintering Fails and How to Guarantee Uniformity

- The Hidden Saboteur in Your High-Temperature Furnace: Why Your Melts Are Inconsistent—And How to Fix It

- Why Your Thermal Processing Fails: The Hidden Mismatch in Your Furnace

- Why Your High-Temperature Furnace Fails: It’s Not the Heating Element, It’s the Physics

- Beyond the Checklist: Why Your High-Temperature Furnace Fails (And How to Ensure It Won't)