Imagine this: You’ve just completed a critical, multi-day heat treatment process in your vacuum furnace. The parameters were set perfectly. The safety checklist was followed to the letter. Yet, when you finally open the chamber, the result is a failure—a cracked sample, an oxidized surface, or inconsistent material properties. The project is set back, and you're left wondering: "I did everything by the book, so what went wrong?"

This scenario is far too common in advanced material science and R&D labs. It's a frustrating experience that undermines confidence and consumes valuable resources.

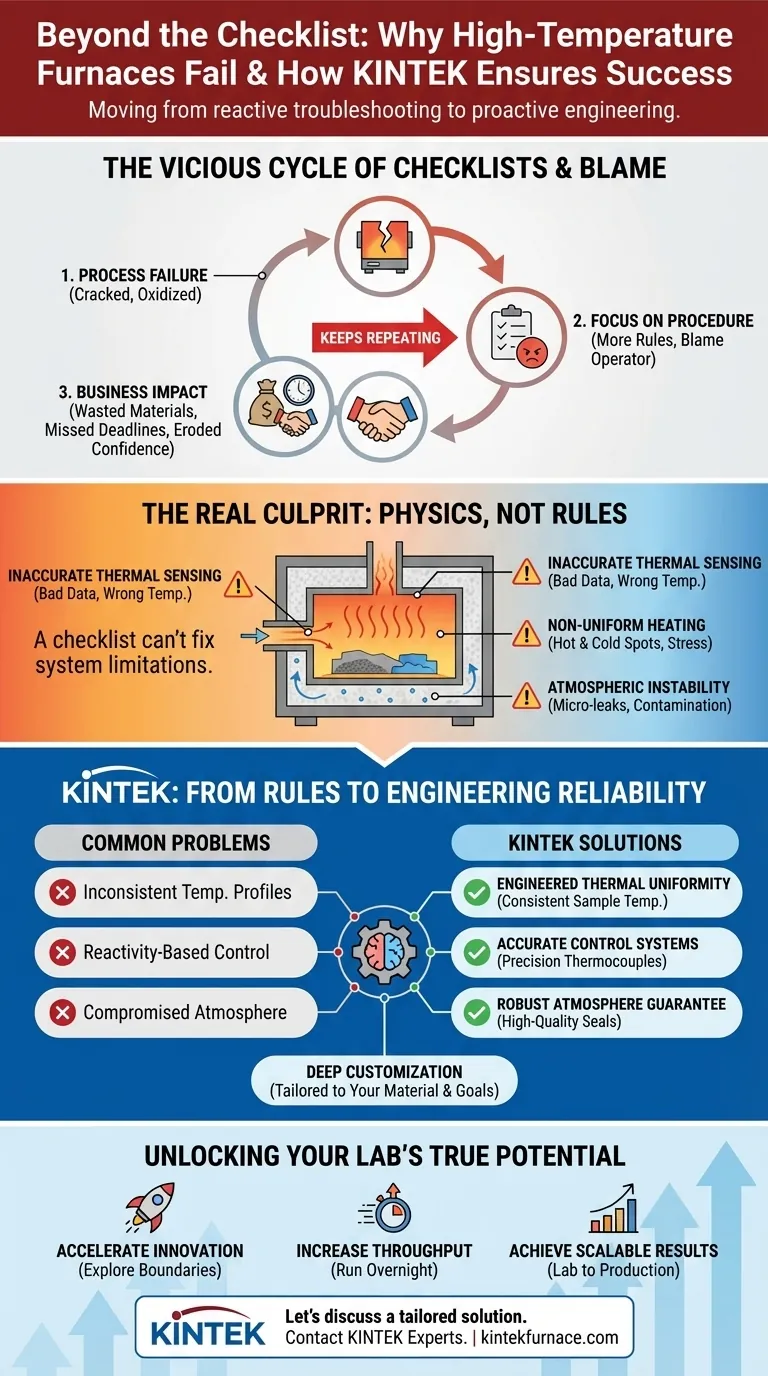

The Vicious Cycle of Checklists and Blame

When a high-temperature process fails unexpectedly, the typical response is to focus on operator procedure. We create more detailed checklists, add more manual monitoring points, and re-emphasize the importance of following the safety manual. We might try to solve the problem by:

- Adding more steps: Insisting on double-checking temperature readings every 15 minutes.

- Creating stricter rules: Forbidding anyone from even touching the control panel during a critical ramp-up.

- Blaming "operator error": Assuming someone must have missed a step, even when there's no evidence.

While well-intentioned, these efforts rarely solve the underlying problem. Instead, they create a culture of anxiety. The real business consequences are significant:

- Wasted High-Value Materials: Every failed run means scrapping expensive, custom-synthesized materials or precision-engineered components.

- Missed Project Deadlines: Unpredictable results make it impossible to stick to R&D timelines, delaying product launches and new discoveries.

- Eroded Confidence: When you can't trust your equipment to produce repeatable results, you can't confidently scale a process from the lab to production.

The cycle continues because these "solutions" are focused on the symptoms, not the root cause.

The Real Culprit: It's Not the Rules, It's the Physics

The frustration stems from a common misconception. We often treat a vacuum furnace like a simple kitchen oven: set the temperature, wait, and you're done. But in reality, a high-temperature furnace is a dynamic environment where extreme heat, low pressure, and material chemistry are in a delicate, constant interplay.

The safety rules—like not exceeding max temperature or opening the door while hot—are critical, but they are designed to prevent catastrophic failure, not guarantee process success. Relying on them alone is like driving a car with an inaccurate speedometer and a loose steering wheel; you can follow the traffic laws perfectly and still end up in a ditch.

The true reason for process failure is often embedded in the furnace's design itself:

- Inaccurate Thermal Sensing: A single thermocouple in the wrong place might tell the controller the chamber is at 1200°C, while your sample is actually experiencing 1250°C. A longer checklist can't fix bad data.

- Non-Uniform Heating: Poorly designed heating elements can create hot and cold spots within the chamber. This thermal gradient induces stress in your material, leading to cracks and warping during the cooldown phase, no matter how slowly you think you're cooling it.

- Atmospheric Instability: A microscopic leak in a seal, imperceptible at room temperature, can introduce just enough oxygen at high temperatures to ruin an oxygen-sensitive material, even if the vacuum gauge reads "normal."

The common solutions fail because they ask the operator to manually compensate for a system that is not inherently stable or precise. You can't solve a physics problem with a checklist.

From Following Rules to Engineering Reliability

To truly solve this, you don’t need more rules; you need a tool built on a deeper understanding of the problem. You need a furnace where precision, uniformity, and safety are not afterthoughts but core design principles.

This is where intelligent furnace design moves beyond a simple safety manual. It's about creating a system that makes the correct outcome the most likely outcome.

How KINTEK Furnaces Embody This Principle

At KINTEK, our foundation in R&D and in-house manufacturing allows us to address these core physical challenges directly. Our furnaces are not just assembled parts; they are integrated systems designed for process integrity.

- Tackling Thermal Uniformity: We don't just put heating elements in a box. We engineer their placement and power distribution to ensure your entire sample experiences a consistent, uniform temperature. This minimizes internal stresses and is the first step to a successful, repeatable process.

- Ensuring Accurate Control: Our Vacuum & Atmosphere Furnaces and CVD/PECVD Systems utilize advanced control systems with strategically placed, high-accuracy thermocouples. The system isn't just reacting to a single data point; it's managing a stable thermal environment based on a true understanding of the chamber's condition.

- Guaranteeing Process Atmosphere: We build robust chambers and use high-quality seals because we know that maintaining vacuum integrity or a pure inert atmosphere is non-negotiable for modern materials. Our systems are designed to be trusted.

Most importantly, our deep customization capability means we don't force your unique process into a generic furnace. We work with you to understand your material and goals, then engineer a solution that is perfectly matched to your application, ensuring the physics are working for you, not against you.

Beyond Troubleshooting: Unlocking Your Lab's True Potential

What happens when you no longer have to fight your equipment? When process reliability becomes the default, your lab's potential is unlocked.

- Accelerate Innovation: Researchers can confidently run more ambitious, complex thermal profiles to explore the true boundaries of new materials, knowing the furnace will execute the plan precisely.

- Increase Throughput: Teams can run processes overnight with confidence, freeing up skilled personnel for higher-value work instead of babysitting a machine.

- Achieve Scalable Results: The consistency achieved in an R&D furnace can be reliably replicated, creating a smooth and predictable path from laboratory discovery to full-scale production.

You move from a reactive state of constant troubleshooting to a proactive state of discovery and development.

Your work is too important to be derailed by equipment you can't trust. Instead of adding another page to your safety checklist, consider whether you have the right tool for the job. Our team of experts understands the complex interplay of heat, atmosphere, and materials that defines a successful thermal process. Let's discuss how a furnace tailored to your specific project can eliminate variability and transform your results. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

Related Articles

- The Invisible Saboteur: Why Your High-Temp Furnace Fails (And How to Stop It)

- Cracked Crucibles, Inconsistent Data? The Post-Heating Step You're Missing

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube

- Beyond the Program: Why Your Sintering Fails and How to Guarantee Uniformity

- Why Your High-Temperature Experiments Fail—And How to Fix Them for Good