You’ve spent weeks preparing a novel material. The precursors are pure, the calculations are perfect, and the process is meticulously planned. You place the sample in the tube furnace, set the temperature to 1150°C, and begin the hours-long synthesis cycle. The next morning, you retrieve the sample, only to find it’s cracked, incompletely reacted, or has wildly different properties than the last batch. The experiment is a failure, and you're back at square one, unsure what went wrong.

If this scenario feels painfully familiar, you are not alone.

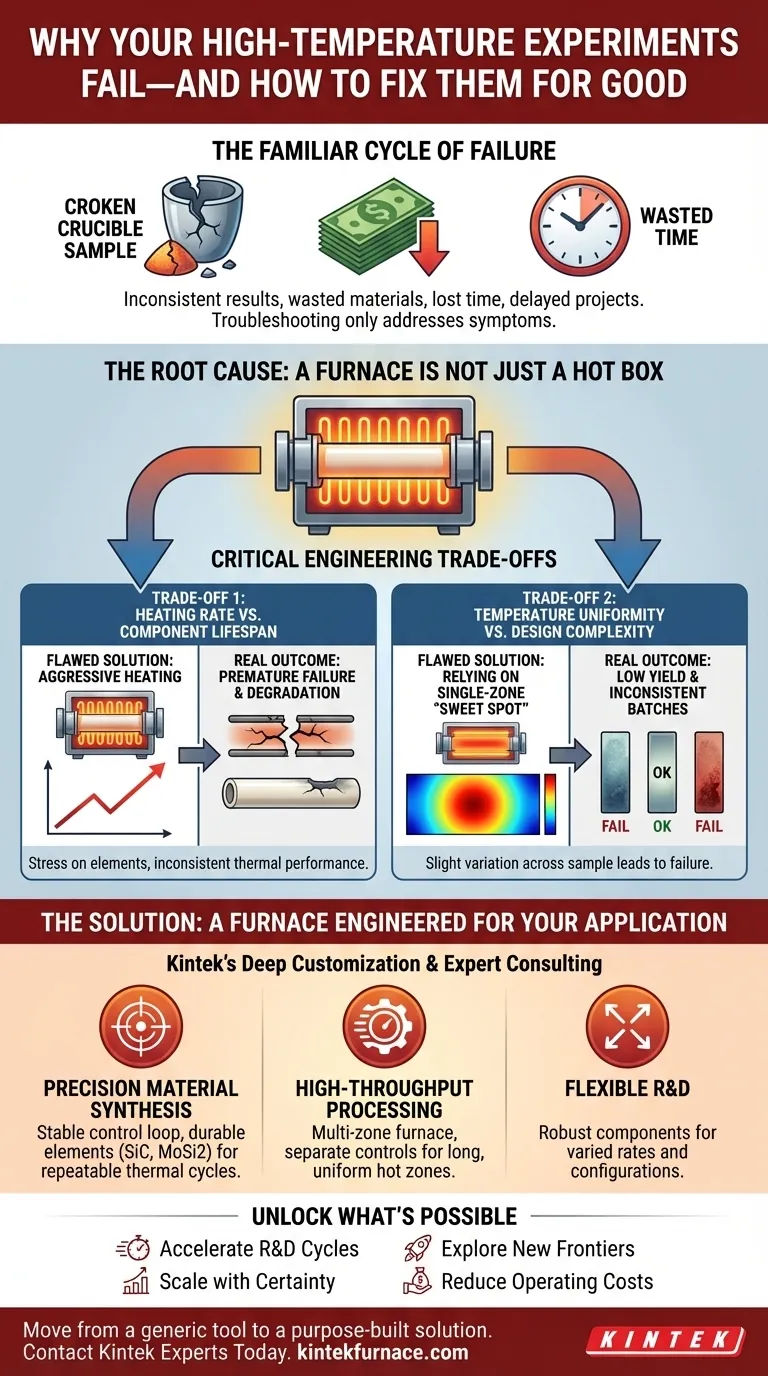

The Familiar Cycle of Trial, Error, and Wasted Resources

In laboratories worldwide, researchers often find themselves trapped in a frustrating loop. When a high-temperature experiment yields inconsistent or failed results, the typical response is to start troubleshooting the most obvious variables:

- "Maybe the precursor ratios were off." So you meticulously re-measure and try again.

- "Perhaps there was a contaminant." You clean everything and repeat the process.

- "This furnace must be unreliable." You blame the equipment and hope the next run is simply "luckier."

Each failed attempt isn't just a scientific setback; it has serious business consequences. It means wasted high-purity materials, lost weeks of valuable R&D time, and delayed project timelines. For a company, this translates directly into higher operational costs, a slower time-to-market for new products, and a growing uncertainty in your research data.

But what if the problem isn't your chemistry or a faulty machine? What if the root cause is a fundamental misunderstanding of the tool itself?

The Root Cause: A Furnace Isn't Just a Box That Gets Hot

The common perception of a furnace is that it’s like a kitchen oven: you set a temperature, and it reliably holds it. This assumption is the source of countless failures. The reality is that a high-temperature furnace is a precision instrument built on a series of critical engineering trade-offs. Treating it like a simple "hot box" means you're unknowingly working against its design.

Here are the two most critical trade-offs that determine the success or failure of your work:

Trade-off 1: Heating Rate vs. Component Lifespan

It’s tempting to ramp up the temperature as fast as possible to save time. However, an aggressive heating rate puts immense thermal stress on the core components—the heating elements and the ceramic process tube. Pushing the furnace too hard is like constantly redlining a car's engine; you might get there faster in the short term, but you guarantee premature failure. The coiled heating elements can degrade, and the ceramic tube can develop micro-cracks, leading to catastrophic failure and inconsistent thermal performance long before then.

- The flawed solution: Running faster cycles to make up for lost time.

- The real outcome: You accelerate the degradation of your furnace, leading to even more unpredictable results and costly repairs.

Trade-off 2: Temperature Uniformity vs. Design Complexity

In a standard, single-zone tube furnace, it's a law of physics that the temperature at the very center of the tube will be slightly hotter than at the ends. For many applications, this is acceptable. But for processes that require exceptional consistency across a larger sample—like growing a crystal or annealing a long component—this slight variation can be the difference between success and failure. Expecting perfect uniformity from a furnace not explicitly designed for it is a recipe for inconsistent batches.

- The flawed solution: Repeatedly running tests and hoping the sample lands in the "sweet spot."

- The real outcome: You get a low yield of usable material, with most of your sample being processed at the wrong temperature.

These common "solutions" fail because they only address the symptoms. To truly solve the problem, you need a tool that is correctly aligned with the demands of your specific task from the very beginning.

The Solution: A Furnace Engineered for Your Application, Not Just a Temperature

The key to repeatable, reliable high-temperature results is to stop fighting the inherent trade-offs of a generic furnace. Instead, you need a furnace where those trade-offs have been intentionally balanced to meet your exact experimental needs.

This is where understanding the core design becomes paramount. The solution isn't just a "better" furnace; it's the right furnace.

- For precision material synthesis: You need a system with an exceptionally stable control loop and heating elements (like advanced SiC or MoSi2) that can handle precise, repeatable thermal cycles without degrading.

- For high-throughput processing: You need a multi-zone furnace explicitly designed with separate heating coils and controls to create a long, exceptionally uniform hot zone, ensuring every sample in the batch is processed identically.

- For flexible R&D: You need a system designed with robust components that can handle varied heating rates without compromising lifespan, perhaps with versatile configurations for horizontal or vertical operation.

At KINTEK, we operate as expert consultants first and manufacturers second. Our deep customization capability isn't just an add-on; it's our core philosophy. We don't start with a product; we start with your goal. By understanding whether you need to prioritize speed, uniformity, or flexibility, we engineer a furnace solution that builds your success into its very design.

Beyond Consistency: What's Possible When Your Furnace is a Partner, Not a Problem?

When you no longer have to second-guess your equipment, a profound shift happens. Your team's energy is liberated from troubleshooting and redirected toward innovation.

With a furnace precisely tailored to your application, you can:

- Accelerate R&D Cycles: Trustworthy, repeatable data means you can make decisions faster and move projects forward with confidence.

- Scale with Certainty: Seamlessly move from small-scale lab synthesis to pilot-scale production, knowing your results will remain consistent.

- Explore New Frontiers: Tackle more ambitious projects involving sensitive materials that require an uncompromising level of thermal stability and control.

- Reduce Operating Costs: An efficient, durable furnace designed for its task consumes less energy and requires fewer repairs, lowering its total cost of ownership.

Your furnace should be an enabler of your research, not an obstacle. The difference lies in moving from a generic tool to a purpose-built solution. If you're ready to break the cycle of failed experiments and unlock the full potential of your lab's high-temperature processes, our team is here to help design the precise instrument you need. Let's discuss the unique demands of your project and engineer a solution that makes consistency the standard. Contact Our Experts.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

Related Articles

- Beyond the Checklist: Why Your High-Temperature Furnace Fails (And How to Ensure It Won't)

- Why Your High-Temperature Synthesis Results Are Unreliable—And How to Fix It

- Gravity and Heat: The Elegant Engineering of the Drop Tube Furnace

- Mastering the Void: How Tube Furnaces Forge the Atoms of Innovation

- Cracked Crucibles, Inconsistent Data? The Post-Heating Step You're Missing