The Unseen Architecture of Our World

Every smartphone, electric vehicle, and data center is built upon a foundation of near-perfect materials. Their performance isn't just a matter of design; it's a matter of atomic-level purity and structural integrity.

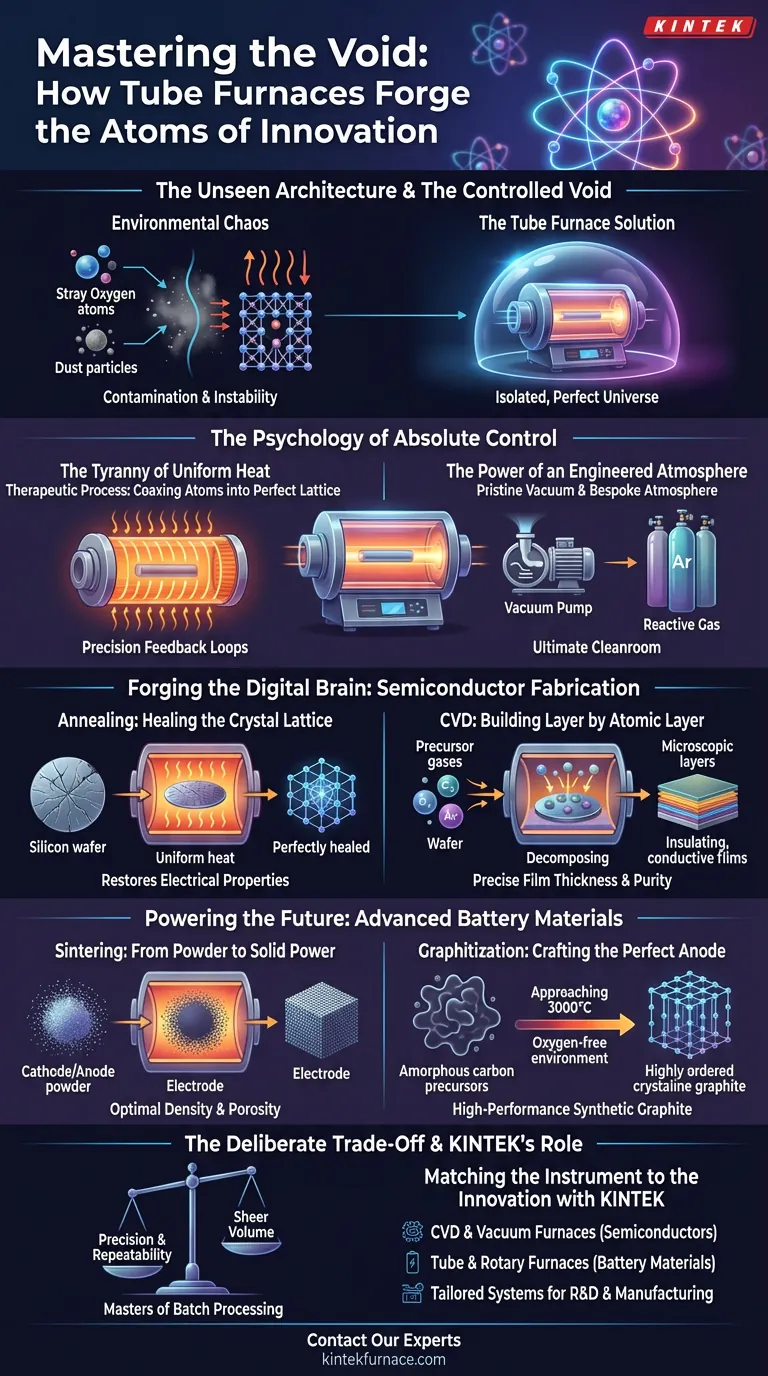

The silent, relentless enemy in creating these materials is the environment itself. A single stray oxygen atom or a microscopic temperature fluctuation can corrupt a silicon wafer or cripple a battery electrode, rendering it useless. The pursuit of modern technology is, in many ways, a psychological battle against this environmental chaos.

The solution isn't to fight the chaos, but to eliminate it. This requires creating a small, perfect, and isolated universe—a controlled void where materials can be forged without interference. This is the profound role of the tube furnace.

The Psychology of Absolute Control

At its heart, a tube furnace is not just a tool for generating heat. It is an instrument for imposing order. It masters two fundamental variables that dictate the fate of high-performance materials: temperature and atmosphere.

The Tyranny of Uniform Heat

In processes like crystal growth or wafer annealing, non-uniform heating is catastrophic. It creates thermal stress, defects, and inconsistencies. The cylindrical geometry of a tube furnace is elegant in its simplicity, delivering exceptionally uniform radiant heat to the material within.

This isn't just warming something up; it's a therapeutic process, like gently coaxing atoms back into a perfect crystal lattice. Sophisticated feedback loops maintain this thermal stability with a precision that borders on obsession, because at the atomic scale, perfection is the only acceptable standard.

The Power of an Engineered Atmosphere

The most critical function is the ability to create a bespoke atmosphere. By first evacuating the chamber to a high vacuum, the furnace removes the reactive, contaminating gases of our natural environment.

From this pristine vacuum, a new world can be built. The chamber can be backfilled with a specific inert gas like argon to prevent reactions, or a precise reactive gas to initiate a process like Chemical Vapor Deposition (CVD) . It's the ultimate cleanroom, scaled down to a few cubic centimeters.

Forging the Digital Brain: Semiconductor Fabrication

In semiconductor manufacturing, the goal is to manipulate silicon at the atomic level. The tube furnace provides the sterile, stable operating theater required for such delicate surgery.

Annealing: Healing the Crystal Lattice

Processes like ion implantation are brutal, scarring the silicon wafer's crystal structure. Annealing is the healing process. Inside a tube furnace, the wafer is bathed in uniform heat within a vacuum or inert atmosphere. This allows the displaced atoms to relax and reorganize, repairing the damage and restoring the wafer's vital electrical properties.

Chemical Vapor Deposition (CVD): Building Layer by Atomic Layer

Microchips are built like microscopic skyscrapers, with layers of insulating and conductive films. CVD is the process that deposits these films. A reactive precursor gas is introduced into the hot furnace, where it decomposes on the wafer's surface, leaving behind a perfectly thin, solid film. The furnace's absolute control over temperature and gas composition dictates the film's thickness, purity, and quality.

Powering the Future: Advanced Battery Materials

A battery's performance—its capacity, lifespan, and safety—is dictated by the chemistry and structure of its electrode materials. Tube furnaces are the crucibles where these next-generation materials are born.

Sintering: From Powder to Solid Power

Cathode and anode materials often start as fine powders. Sintering uses high heat—below the melting point—to fuse these particles into a solid, dense mass. Performing this in a tube furnace's controlled atmosphere prevents oxidation, ensuring the final electrode has the optimal density and porosity. This structure is what allows lithium ions to move efficiently, directly impacting the battery's performance.

Graphitization: Crafting the Perfect Anode

The high-performance synthetic graphite in many lithium-ion battery anodes doesn't exist in nature. It's created through graphitization, an extreme-heat process (often approaching 3000°C) that transforms amorphous carbon precursors into a highly ordered crystalline structure. This must be done in an oxygen-free environment to prevent the carbon from simply burning away, making the tube furnace an indispensable tool.

The Deliberate Trade-Off: Precision Over Volume

Tube furnaces are masters of batch processing. This isn't a limitation; it's a feature. They are designed for the high-stakes world of research, development, and high-value production where absolute precision and repeatability are more important than sheer throughput.

Achieving this level of control requires a holistic system. It's not just the furnace, but the network of vacuum pumps, mass flow controllers, and safety interlocks working in concert. This complexity is the price of admission for manufacturing the materials of the future.

Matching the Instrument to the Innovation

Your choice of furnace depends entirely on the problem you're trying to solve.

- For semiconductor purity, the focus is on high-vacuum capability and ultra-pure gas delivery to eliminate all sources of contamination.

- For battery performance, the priority is achieving large, uniform temperature zones and maintaining a stable inert atmosphere for complete material conversion.

- For fundamental research, versatility is key—a system that can handle different tube sizes, temperatures, and atmospheres to explore the unknown.

This level of specificity is why one-size-fits-all solutions fall short. True innovation requires an instrument engineered for the task. At KINTEK, we specialize in developing these tailored systems, from advanced CVD and Vacuum Furnaces for semiconductor research to robust Tube and Rotary Furnaces for battery material synthesis. By integrating R&D with manufacturing, we build the precise environment your work demands.

Whether refining semiconductor wafers or pioneering new battery chemistries, achieving this level of control requires a furnace tailored to your exact process. Contact Our Experts

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

Related Articles

- The Physics of Control: Mastering the Three-Stage Journey of Heat in a Tube Furnace

- Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

- The Geometry of Control: Why Tube Furnaces Define Modern Materials

- A War Against Chaos: The Elegant Engineering of the Modern Tube Furnace

- Mastering the Micro-Environment: The Art and Science of the Laboratory Tube Furnace