The All-Too-Familiar Story of a Failed Experiment

You’ve spent weeks, maybe months, developing a protocol for a new temperature-sensitive material. The precursors are pure, the calculations are sound, and the procedure is followed to the letter. You carefully load the sample into your tube furnace, initiate the complex heating program, and wait.

Hours later, you retrieve the result, only to find it’s a failure. Perhaps the crystal didn’t grow correctly, the thin film is contaminated, or the alloy’s properties are wildly inconsistent. It’s a baffling and costly setback. What went wrong?

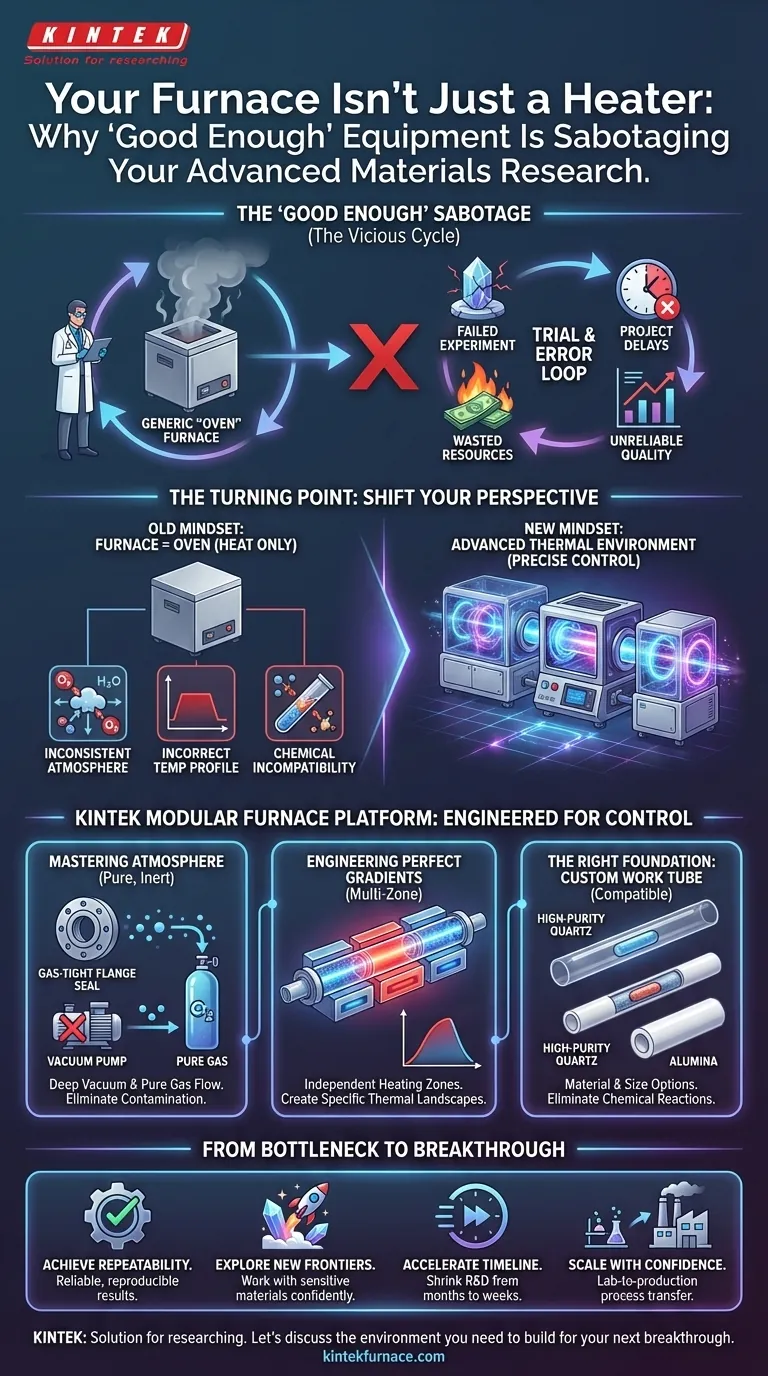

The Vicious Cycle of "Trial and Error" and Its Hidden Costs

If this scenario sounds familiar, you are not alone. Across countless advanced research and production labs, teams find themselves stuck in a frustrating loop. They blame the raw materials. They tweak the temperature ramps by a few degrees. They adjust gas flow rates, hoping for a different outcome. They run the same experiment again and again, burning through time, expensive materials, and team morale.

This isn't just an academic inconvenience; it has severe business consequences:

- Project Delays: R&D timelines are pushed back, delaying publications and slowing down the product development pipeline.

- Wasted Resources: Every failed run consumes costly, high-purity materials and valuable energy.

- Unreliable Quality: For production environments, this inconsistency leads to lower yields and questions about product reliability.

Many labs eventually conclude their standard furnace just isn't "good enough" and look for another off-the-shelf model. But often, the new equipment produces the same old problems, because the issue isn't a lack of quality—it's a fundamental misunderstanding of the tool's role.

The Real Culprit: Treating Your Furnace Like an Oven

Here is the turning point: The problem isn’t your process. It’s your perspective. We are conditioned to think of a furnace as a simple box that gets hot—an oven. But for advanced materials science, this is a dangerous oversimplification.

A standard furnace provides heat. An advanced thermal process, however, requires a meticulously engineered environment. You are not just baking a sample; you are orchestrating a delicate reaction where temperature, atmosphere, and physical space must work in perfect harmony.

Why Common Fixes Fail

This is why the "trial and error" approach rarely works. You're adjusting the symptoms without diagnosing the disease.

- Inconsistent Atmosphere: You tweak gas flow, but your system isn't truly gas-tight. Trace amounts of oxygen or moisture leak in, contaminating your oxygen-sensitive sample.

- Incorrect Temperature Profile: You program a precise temperature, but a single heating zone can't create the stable, specific temperature gradient your crystal growth or CVD process requires along the length of the tube.

- Chemical Incompatibility: The standard quartz tube you're using may be subtly reacting with your material at high temperatures, introducing impurities and skewing your results.

You have been trying to force a highly specific, sensitive process into a generic, one-size-fits-all box. The real solution is to stop forcing the fit and start building the perfect environment from the ground up.

Designing Your Solution: The Modular Furnace Platform

To gain absolute control, you need to stop thinking of a furnace as a single product and start seeing it as a modular platform. You need a tool designed not just to get hot, but to give you precise, independent control over every critical variable. This is the philosophy behind our engineering at KINTEK.

Our furnaces are designed as a system of solutions that directly address the root causes of experimental failure.

Mastering the Atmosphere

The first step for many processes is removing the uncontrolled variable of ambient air. A truly effective system must allow you to achieve a deep vacuum, purging reactive gases, and then introduce a specific, ultra-pure atmosphere. With our precision-engineered, gas-tight flange seals and integrated vacuum systems, you move from "mostly inert" to a truly controlled environment, eliminating oxidation and contamination as a source of failure.

Engineering the Perfect Temperature Gradient

For processes like CVD or crystal growth, uniform heat isn't enough. You need specific temperature zones. Our multi-zone tube furnaces feature independently controlled heating segments. This allows you to build a precise thermal landscape along the tube—a stable hot zone in the middle with cooler ends, for example—giving you the exact gradient your process demands for repeatable success.

The Right Foundation: The Work Tube

The tube itself is an active component of your experiment. We offer deep customization of the work tube's material (e.g., high-purity quartz, alumina), diameter, and length. By matching the tube to your specific chemical and physical requirements, you eliminate reactions and ensure the physical space is perfectly suited to your sample size and process needs.

From Bottleneck to Breakthrough: What's Possible with the Right Tool?

When you stop fighting your equipment and start with a tool designed for your process, the entire dynamic of your work changes. The furnace is no longer a bottleneck; it becomes an accelerator for innovation.

- Achieve Repeatability: Move from frustrating inconsistency to reliable, reproducible results you can trust, experiment after experiment.

- Explore New Frontiers: Confidently work with highly sensitive or reactive materials that were previously impossible to handle in your old setup.

- Accelerate Your Timeline: Drastically reduce the "trial and error" phase. When your first run works, your entire project timeline shrinks from months to weeks.

- Scale with Confidence: Develop a process on a lab-scale system, knowing that the same environmental principles can be scaled up for pilot or full-scale production.

Your research is unique and your standards are high. Don't let a generic tool dictate the limits of your ambition. By engineering the right thermal environment, you unlock the full potential of your materials and your team.

We understand that your challenges are specific. Our strength lies not just in our diverse product line, but in our ability to work with you to configure a furnace solution that precisely matches your application's unique demands. Let's discuss the environment you need to build for your next breakthrough. Contact Our Experts.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

Related Articles

- Mastering the Void: How Tube Furnaces Engineer Predictable Outcomes

- The Physics of Mismatched Tools: Why a Tube Furnace Isn't for Wastewater

- Mastering the Micro-Environment: The Art and Science of the Laboratory Tube Furnace

- Mastering the Void: How Tube Furnaces Forge the Atoms of Innovation

- The Controlled Universe: Why Tube Furnaces Prioritize Precision Over Scale