Vacuum Furnace

Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Item Number : KT-VF

Price varies based on specs and customizations

- Max. temperature

- 1200°C / 1700℃

- Temperature control accuracy

- ±1℃

- Temperature uniformity

- ±5℃

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD/MPCVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

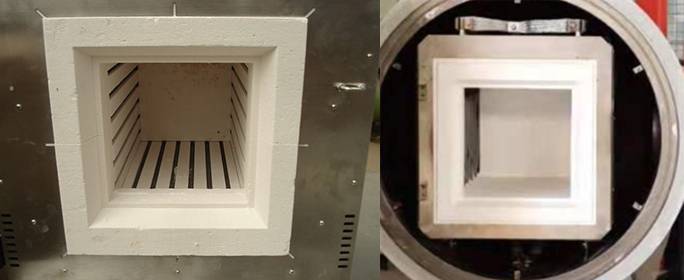

KINTEK Vacuum Furnace with Ceramic Fiber Lining: Precision High-Temperature Processing

[Original Image Would Be Here - I will place a placeholder comment as I cannot embed the actual image, but the provided image should be at the top of the product content, below this heading]

KINTEK's Vacuum Furnace with Ceramic Fiber Lining is engineered for superior performance in demanding laboratory and small-scale production environments. Utilizing advanced ceramic fiber insulation, this furnace ensures excellent thermal efficiency, precise temperature control, and uniform heat distribution for a variety of high-temperature processes.

Key Performance Highlights

- Two Working Temperature Ranges:

- 1200°C Max: Employs Cr2Al2Mo2 resistance wire coil heating elements and polycrystalline ceramic fiber liners. Ideal for a wide range of heat treatment processes.

- 1700°C Max: Features Molybdenum Disilicide (MoSi2) heating elements and high-purity polycrystalline ceramic fiber liners for ultra-high temperature applications.

- Superior Insulation: Lightweight, porous ceramic fiber lining offers excellent thermal insulation, significantly reducing heat loss, improving energy efficiency by over 50% compared to traditional furnaces, and ensuring faster heat-up and cool-down times.

- Precise Temperature Control: Equipped with a touch screen PID controller and PLC, offering temperature accuracy of ±1℃ and uniformity of ±5℃.

- High Vacuum Performance: Achieves vacuum levels up to 6*10-3Pa, with an excellent vacuum pressure maintaining performance (low pressure rise rate of 0.67Pa/h).

Explore the Design and Construction

The furnace chamber adopts high-density light alumina ceramic fiber, ensuring a stable structure, excellent thermal shock performance, and thermal stability. This advanced material provides good insulation performance, low heat capacity, and low thermal conductivity, leading to energy savings of more than 50% compared with traditional silicon carbide furnaces.

Core Advantages & Features

Our vacuum furnaces are designed to deliver consistent, high-quality results with operational efficiency:

- Enhanced Material Integrity: The vacuum environment prevents surface oxidation and discoloration, ensuring pristine workpiece finishes.

- Minimal Distortion: Uniform heating and controlled cooling rates minimize thermal stresses, significantly reducing material distortion.

- Flux-Free Brazing: Enables high-purity brazing without the need for flux, eliminating post-brazing cleaning processes.

- Repeatable Quality: Precise control over temperature and atmosphere ensures consistent and reproducible outcomes for every cycle.

- Energy Efficiency: Advanced ceramic fiber insulation minimizes heat loss, contributing to lower energy consumption and operational costs.

- Clean, Safe, and Quiet Operation: Operates within a closed system, minimizing emissions and noise for a better laboratory environment.

- User-Friendly Controls: Features a PID programmable microprocessor temperature control system for precise and reliable heating cycles.

Versatile Applications

KINTEK vacuum furnaces with ceramic fiber lining are indispensable tools across various industries and research fields, including:

- Vacuum Heat Treatment: Hardening, tempering, annealing, and stress relieving of metals and alloys.

- Vacuum Brazing: Joining of metal components, creating strong and clean bonds.

- Sintering: Compacting and forming solid masses of material by heat and pressure, widely used for ceramics, metals, and composites.

- Degassing: Removing trapped gases from materials such as metals and ceramics to improve their properties and performance.

- High-Temperature Processing: Providing a controlled, clean, and safe environment for various material processing tasks at elevated temperatures.

Working Principle

The KINTEK vacuum furnace operates by utilizing robust heating elements (Cr2Al2Mo2 resistance wire or Molybdenum Disilicide, depending on the model) to heat the furnace chamber. The high-efficiency ceramic fiber lining insulates the chamber, minimizing heat loss and ensuring temperature uniformity. A powerful vacuum pump evacuates air from the chamber, creating the necessary vacuum environment. This vacuum prevents oxidation of the materials being processed and allows for highly precise temperature control, regulated by an advanced temperature controller.

Technical Specifications

| Furnace model | KT-VF12 / KT-VF17 |

|---|---|

| Max. temperature | 1200°C / 1700℃ |

| Constant work temperature | 1100°C / 1600℃ |

| Chamber material | Ceramic polycrystalline fiber |

| Heating element | Cr2Al2Mo2 wire coil / Molybdenum Disilicide (MoSi2) |

| Heating rate | 0-20℃/min (Adjustable) |

| Temperature sensor | Built-in K-type / B-type thermocouple |

| Temperature controller | Touch screen PID controller with PLC |

| Temperature control accuracy | ±1℃ |

| Temperature uniformity | ±5℃ |

| Electric power supply | AC110-440V, 50/60HZ (Customizable) |

Standard Chamber Sizes

| Standard Chamber Sizes Available (Customization Welcomed) | |||

|---|---|---|---|

| Chamber size (mm) (D x W x H) | Effective volume (L) | Chamber size (mm) (D x W x H) | Effective volume (L) |

| 100x100x100 | 1 | 400x400x500 | 80 |

| 150x150x200 | 4.5 | 500x500x600 | 125 |

| 200x200x300 | 12 | 600x600x700 | 253 |

| 300x300x400 | 36 | 800x800x800 | 512 |

| Custom-designed sizes and volumes are accepted to meet your specific research needs. | |||

Need a specific chamber size or configuration? We specialize in tailoring furnaces to your exact requirements. Contact us to discuss your custom design.

Optional Setup & Advanced Customizations

Enhance your vacuum furnace with a range of optional features:

- Independent furnace temperature monitoring and recording system.

- RS 485 communication port for PC remote control and data exporting.

- Optional pneumatic vacuum valve linkage integrated with the temperature controller.

- Advanced touch screen temperature controller with versatile, operator-friendly functions.

- Cold water circulation cooling machine for efficient furnace shell jacket cooling.

Advanced Safety Systems

Safety is paramount in KINTEK furnace designs:

- Over-Current and Over-Temperature Protection: The furnace automatically shuts off power and alarms if over-current or over-temperature conditions are detected.

- Thermocouple Failure Detection: The system continuously monitors the thermocouple. If a break or failure is detected, heating will stop, and an alarm will activate.

- Power Failure Restart Function: In the event of a power outage, the furnace can be programmed to automatically resume the heating program once power is restored.

- Door Safety Interlock: Automatic power shut-off if the door is opened during operation.

Your Partner for Advanced Thermal Processing

At KINTEK, we understand that every research project and production process has unique demands. Our expertise in high-temperature furnace technology, combined with our commitment to in-house R&D and manufacturing, allows us to offer not just standard products but deeply customized solutions.

Ready to elevate your high-temperature experiments? Whether you require a standard model or a fully customized vacuum furnace, our team is here to assist. Contact us today to discuss your specific requirements, request a quote, or learn more about how KINTEK can be your solution for researching.

Trusted by Industry Leaders

FAQ

What Are The Main Applications Of A Vacuum Furnace?

What Is An Atmosphere Furnace Used For?

What Are The Key Features Of A Vacuum Furnace?

What Are The Key Features Of An Atmosphere Furnace?

How Does A Vacuum Furnace Work?

How Does An Atmosphere Furnace Work?

What Are The Advantages Of Using A Vacuum Furnace?

What Are The Advantages Of Using An Atmosphere Furnace?

What Types Of Materials Can Be Processed In A Vacuum Furnace?

What Types Of Gases Can Be Used In An Atmosphere Furnace?

What Is The Difference Between Hot Wall And Cold Wall Vacuum Furnaces?

What Safety Features Are Available In Advanced Atmosphere Furnaces?

Can Vacuum Furnaces Be Customized For Specific Applications?

4.8 / 5

Incredible durability and efficiency! This furnace outperforms competitors effortlessly.

4.7 / 5

Fast delivery and top-notch quality. A game-changer for our lab!

4.9 / 5

The ceramic fiber liner is a brilliant innovation. Worth every penny!

4.6 / 5

Reliable and advanced tech. Perfect for high-precision heat treatments.

4.9 / 5

Exceptional value for money. The furnace’s performance is unmatched!

4.7 / 5

Superb build quality and energy efficiency. Highly recommended!

4.8 / 5

The vacuum seal is flawless. A must-have for serious metallurgists.

4.7 / 5

Quick setup and outstanding performance. Exceeded all expectations!

4.9 / 5

Cutting-edge technology with robust durability. Simply outstanding!

4.8 / 5

Precision and speed combined. This furnace is a masterpiece.

4.7 / 5

The ceramic liner ensures consistent results. A fantastic investment!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Molybdenum Vacuum Heat Treat Furnace

High-performance molybdenum vacuum furnace for precise 1400°C heat treatment. Ideal for sintering, brazing, and crystal growth. Durable, efficient, and customizable.

600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

600T Vacuum Induction Hot Press Furnace for precise sintering. Advanced 600T pressure, 2200°C heating, vacuum/atmosphere control. Ideal for research & production.

Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

KINTEK's Vacuum Molybdenum Wire Sintering Furnace excels in high-temperature, high-vacuum processes for sintering, annealing, and material research. Achieve precise 1700°C heating with uniform results. Custom solutions available.

Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

Compact vacuum tungsten wire sintering furnace for labs. Precise, mobile design with superior vacuum integrity. Ideal for advanced material research. Contact us!

9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

Achieve superior ceramic densification with KINTEK's advanced air pressure sintering furnace. High-pressure up to 9MPa, precise 2200℃ control.

Vacuum Heat Treat Sintering and Brazing Furnace

KINTEK Vacuum Brazing Furnaces deliver precision, clean joints with superior temperature control. Customizable for diverse metals, ideal for aerospace, medical, and thermal applications. Get a quote!

Vacuum Hot Press Furnace Machine for Lamination and Heating

KINTEK Vacuum Lamination Press: Precision bonding for wafer, thin-film & LCP applications. 500°C max temp, 20-ton pressure, CE certified. Custom solutions available.

Vacuum Hot Press Furnace Machine Heated Vacuum Press

KINTEK Vacuum Hot Pressing Furnace: Precision heating & pressing for superior material density. Customizable up to 2800°C, ideal for metals, ceramics, and composites. Explore advanced features now!

Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

KINTEK's Vacuum Pressure Sintering Furnace offers 2100℃ precision for ceramics, metals, and composites. Customizable, high-performance, and contamination-free. Get a quote now!

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

Precision Vacuum Press Furnace for labs: ±1°C accuracy, 1200°C max, customizable solutions. Boost research efficiency today!

High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

KF ultra-high vacuum observation window with high borosilicate glass for clear viewing in demanding 10^-9 Torr environments. Durable 304 stainless steel flange.

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Reliable CF/KF flange vacuum electrode feedthrough for high-performance vacuum systems. Ensures superior sealing, conductivity & durability. Customizable options available.

304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

KINTEK's 304/316 stainless steel vacuum ball valves and stop valves ensure high-performance sealing for industrial and scientific applications. Explore durable, corrosion-resistant solutions.

Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

KF/ISO/CF ultra-high vacuum stainless steel flange pipe systems for precision applications. Customizable, durable, and leak-tight. Get expert solutions now!

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

KINTEK RF PECVD System: Precision thin-film deposition for semiconductors, optics & MEMS. Automated, low-temperature process with superior film quality. Custom solutions available.

Related Articles

More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

A vacuum furnace is efficient by design. It eliminates convective heat loss, uses advanced insulation, and employs precision controls for direct energy use.

Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation

Mastering a vacuum furnace isn't about temperature; it's about controlling an invisible environment and overcoming the psychological pitfalls of automation.

The Unseen Enemy: Why Vacuum Furnaces Are a Bet on Perfection

Vacuum heat treatment isn't just a process; it's a strategy for eliminating the atmospheric variables that compromise material integrity and finish.

The Pursuit of Purity: Why a Vacuum Furnace Is a System for Creating Certainty

A vacuum furnace isn't just for heating; it's a controlled system for eliminating atmospheric variables, ensuring material purity and repeatability.

The Real Reason Your High-Performance Materials Are Failing (And It’s Not the Alloy)

Tired of inconsistent heat treatment? Discover the two invisible culprits sabotaging your materials and how a vacuum furnace provides the control to fix it for good.

The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection

Vacuum furnaces are not just for heat; they create a controlled void to eliminate oxidation and achieve material properties unattainable in air.

From Brute Force to Perfect Control: The Physics and Psychology of Vacuum Furnaces

Discover how vacuum furnaces transform heat treatment from an unpredictable art into a precise science, offering unparalleled control and material purity.

The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

Discover how vacuum pressing transcends mechanical force, creating a controlled environment to eliminate defects and unlock the full potential of advanced composites.

The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

Discover how vacuum furnaces eliminate atmospheric contamination to achieve superior material quality, consistency, and throughput in modern manufacturing.

The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

Vacuum furnaces aren't just for preventing rust; they create a controlled void to achieve unparalleled material purity, properties, and consistency.

The Physics of Perfection: How a Vacuum Furnace Creates Order from Chaos

Discover how vacuum furnaces achieve material perfection by removing atmospheric chaos, ensuring unparalleled purity, control, and repeatability in heat treatment.

The Physics of Perfection: How Vacuum Furnaces Redefine Material Integrity

Discover how vacuum furnaces achieve ultimate process control by removing atmospheric variables, ensuring superior material properties and part quality.