The Psychology of Pressure

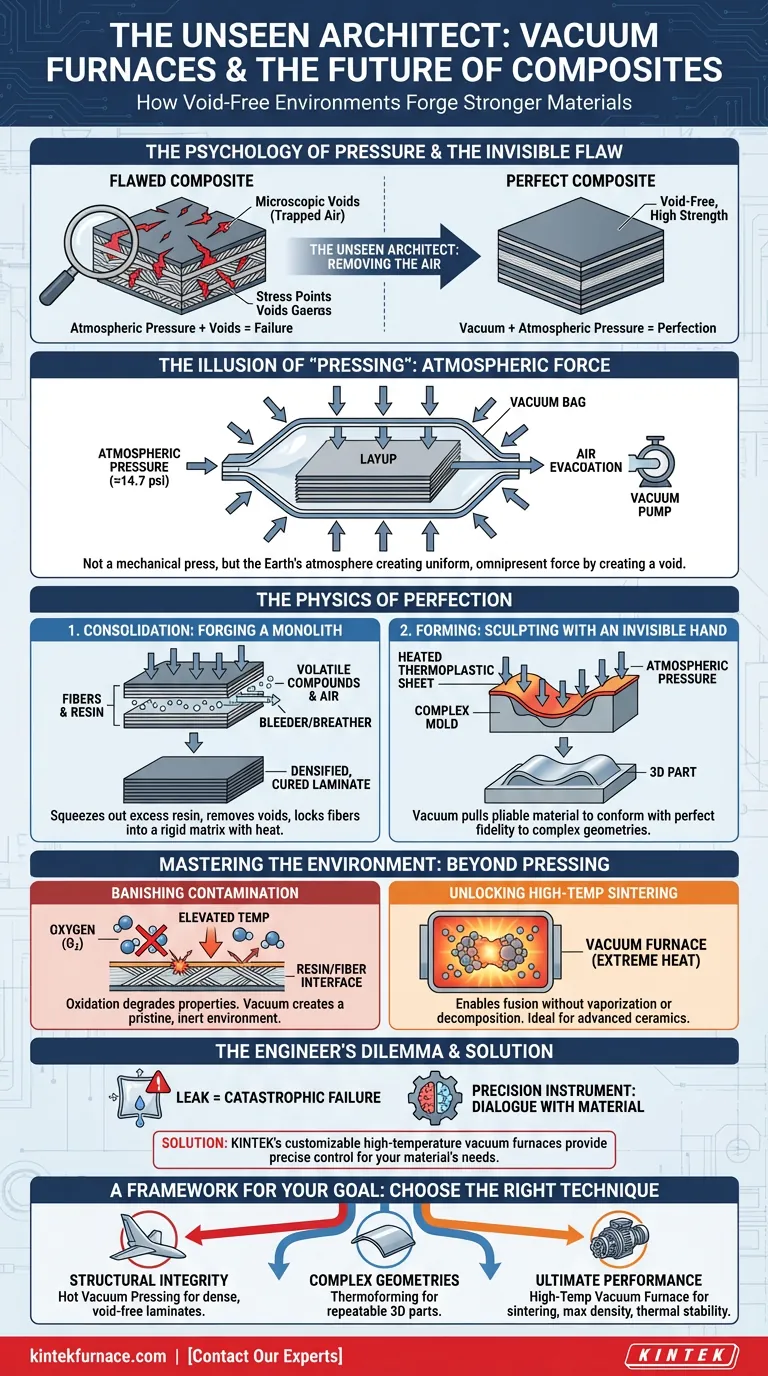

An engineer inspects a newly fabricated composite winglet. To the naked eye, it's perfect. But under load, it fails at 70% of its predicted strength. The culprit is not a design flaw but an invisible one: microscopic voids, tiny bubbles of trapped air that became stress points under pressure.

Our intuition for making things stronger is often to add more force—to press harder, clamp tighter. But in the world of advanced composites, the most powerful technique involves removing something instead: the air itself. This is the counterintuitive genius of vacuum pressing.

The Illusion of "Pressing"

The term "vacuum pressing" is a slight misnomer. We aren't actually pressing with a vacuum. We are creating a void, a sealed environment from which air has been evacuated.

In doing so, we unleash a force that is perfectly uniform, relentlessly consistent, and omnipresent: the Earth's atmosphere. At sea level, that’s about 14.7 pounds per square inch (or ~101 kPa) pressing down on every surface of our part. By removing the air from one side, we let the atmosphere do the work with a precision no mechanical press can match.

The Physics of Perfection: Consolidation and Forming

This principle is harnessed for two primary functions in composite manufacturing, each a delicate dance of heat, pressure, and chemistry.

Forging a Monolith from Layers

Creating a laminate involves stacking layers of fiber (like carbon or glass) impregnated with resin. This stack, or "layup," is then sealed in a vacuum bag.

When the vacuum is applied, atmospheric pressure compresses the stack from every direction. This seamless force:

- Squeezes out excess, weight-adding resin.

- Forces out trapped air and volatile compounds that cause voids.

- Consolidates the distinct layers into a single, dense, unified structure.

When combined with heat in a process called hot vacuum pressing, the resin cures simultaneously, locking the fibers into a rigid, high-strength matrix.

Sculpting with an Invisible Hand

For shaping thermoplastic sheets or pre-impregnated composites, the material is first heated until it becomes soft and pliable.

It is then draped over a mold, and a vacuum is pulled between the sheet and the mold's surface. The atmospheric pressure acts as an invisible hand, forcing the material to conform to every subtle contour of the mold with perfect fidelity. It’s an elegant and efficient method for creating complex, three-dimensional parts.

The Real Game: Mastering the Environment

The true power of vacuum processing isn't just mechanical. It's about taking absolute control of the material's environment at a chemical and physical level. This is where the process moves from simple pressing to high-fidelity fabrication.

Banishing the Contaminant

At elevated temperatures, the oxygen in the air becomes a highly reactive contaminant. It attacks the resin and fibers, causing oxidation that degrades mechanical properties and ruins the surface finish. A vacuum removes this threat, creating a pristine environment where materials can be cured and bonded without corruption.

Unlocking High-Temperature Sintering

For advanced ceramics and certain composites, achieving maximum density requires sintering—a process where material is heated to just below its melting point, causing its particles to fuse.

Many of these materials would simply vaporize or decompose at these temperatures under normal atmospheric pressure. A vacuum furnace creates an environment where extreme heat can be applied without destroying the material, allowing it to densify and sinter under uniform atmospheric pressure.

The Engineer's Dilemma: The Pursuit of Control

This level of control is not without its challenges. The process is a system where every component must work in perfect harmony.

- The Anatomy of a Leak: A microscopic leak in the vacuum bag is a catastrophic failure point. It introduces air, compromises pressure uniformity, and allows voids to form, undoing all the benefits of the process.

- The Material-Machine Dialogue: The resin's viscosity, its curing temperature profile, and the fiber's properties must be perfectly matched to the capabilities of the equipment. The heating rate of the furnace and the efficiency of the vacuum pump are not just settings; they are part of a dialogue with the material itself.

Solving this dilemma requires more than just technique; it requires instrumentation capable of imposing and maintaining a perfect, controlled environment. A vacuum furnace is not just a box that gets hot; it is a precision instrument.

This is where having a system designed for your specific material and process becomes a critical advantage. With expert R&D and manufacturing, KINTEK's customizable high-temperature vacuum furnaces provide engineers with the precise control needed to manage this complex dialogue. Whether it's a standard tube furnace for lab-scale tests or a highly customized CVD system, the goal is to create an environment where the material can achieve its full theoretical potential.

A Framework for Your Goal

The right technique depends entirely on the desired outcome:

- For Structural Integrity: Use hot vacuum pressing to create dense, void-free laminates with a high fiber-to-resin ratio.

- For Complex Geometries: Use thermoforming to cost-effectively shape thermoplastic sheets into repeatable 3D parts.

- For Ultimate Performance: Leverage a high-temperature vacuum furnace to enable sintering, prevent oxidation, and create materials with maximum density and thermal stability.

Ultimately, the art of modern composites lies not in the brute force you apply, but in the perfection of the void you create. For any process that demands absolute control over temperature and atmosphere, achieving a flawless material outcome is paramount. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- Engineering for Zero Failure: The Indispensable Role of Vacuum Furnaces in Aerospace

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation

- The Physics of Perfection: How a Vacuum Furnace Creates Order from Chaos

- The Real Reason Your High-Performance Materials Are Failing (And It’s Not the Alloy)