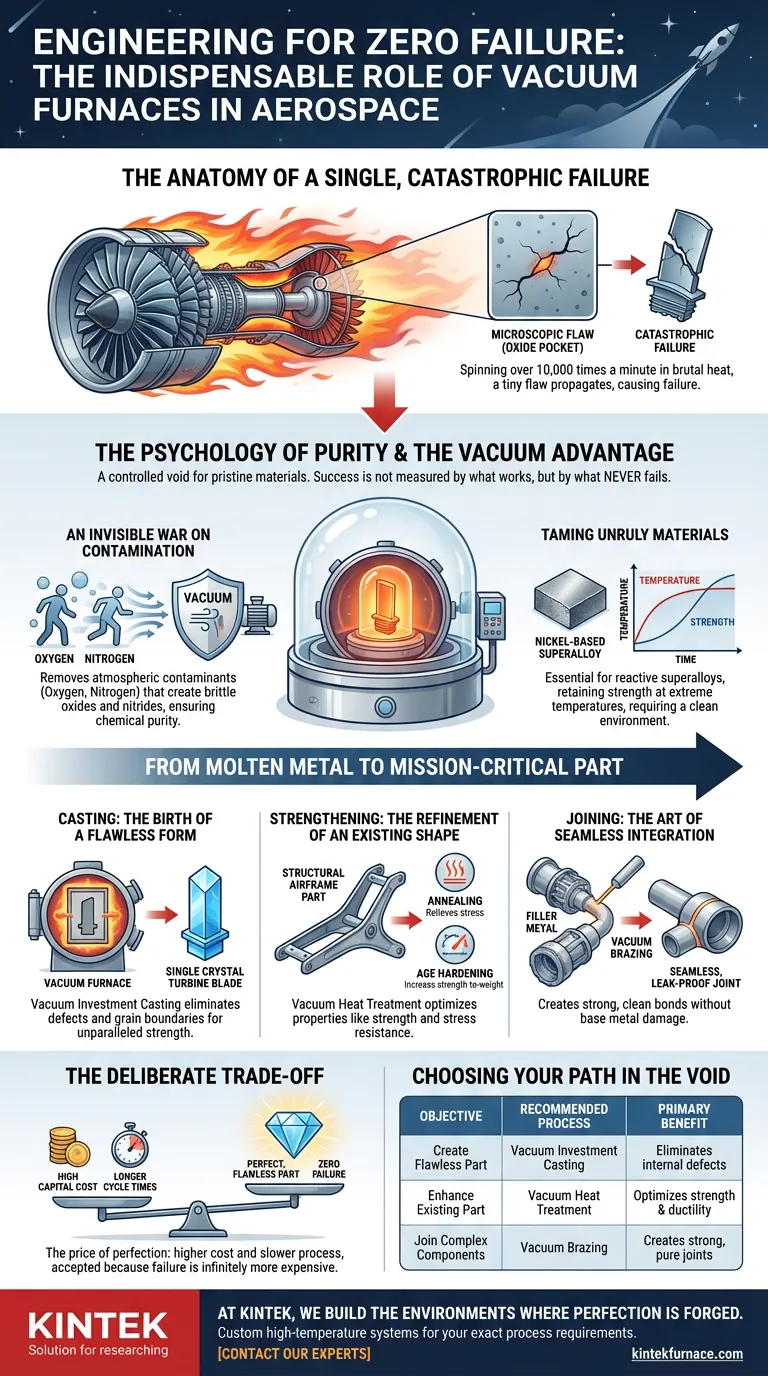

The Anatomy of a Single, Catastrophic Failure

Imagine a jet engine turbine blade, spinning over 10,000 times a minute while bathed in gases hotter than volcanic lava. The forces are immense. The environment is brutal. A single microscopic flaw—a tiny pocket of oxide, an invisible structural weakness—can propagate into a crack, leading to catastrophic failure.

In aerospace engineering, success is not measured by what works, but by what never fails. This relentless pursuit of perfection leads us away from the open air and into a controlled void. The vacuum furnace is not just a piece of equipment; it is the pristine environment where the world's most advanced materials are born.

The Psychology of Purity

The decision to use a vacuum furnace is not a matter of preference. It's a strategic necessity driven by an understanding of risk. At the temperatures needed to cast or treat superalloys, the air we breathe becomes a potent contaminant.

An Invisible War on Contamination

Oxygen and nitrogen are the invisible enemies of metallurgical integrity. At high temperatures, they aggressively bond with reactive metals, creating oxides and nitrides that act like structural poison. They introduce brittleness and weakness.

A vacuum is the only battlefield where this war can be won decisively. By removing the atmosphere, we remove the threat, ensuring the final alloy is chemically pure and behaves exactly as our models predict.

Forging Predictable Strength

Aerospace components demand properties that feel almost contradictory: immense strength, yet resistance to fatigue; rigidity, but not brittleness. These characteristics are not inherent to the metal alone; they are sculpted through precise thermal processes.

Processes like annealing, hardening, and tempering refine a metal's grain structure. Performing them in a vacuum ensures this refinement happens without introducing impurities. It is the difference between building a structure with perfectly cut stones versus using rocks mixed with sand and dirt.

Taming Unruly Materials

Nickel-based superalloys are the bedrock of modern jet engines, retaining their strength at temperatures that would turn lesser metals to liquid. But this strength comes with a volatile, reactive nature.

These alloys can only be processed correctly in a vacuum. The controlled environment is essential for both shaping the part through casting and later optimizing its properties through heat treatment.

From Molten Metal to Mission-Critical Part

A vacuum furnace is a versatile theater for metallurgical transformation, enabling several critical processes.

Casting: The Birth of a Flawless Form

The most demanding application is for parts like turbine blades. Using vacuum investment casting, engineers can create components as single crystals, entirely eliminating grain boundaries—the natural fault lines within a metal. This produces a component with unparalleled strength and heat resistance, born flawless from a molten state.

Strengthening: The Refinement of an Existing Shape

For structural airframe parts, the goal is often to enhance an existing form. Vacuum annealing relieves internal stresses from manufacturing, preventing premature cracks. Vacuum age hardening can dramatically increase the strength-to-weight ratio of titanium and aluminum alloys, allowing for lighter and more robust designs.

Joining: The Art of Seamless Integration

Aerospace systems are networks of complex assemblies. Joining them is a challenge. Vacuum brazing uses a filler metal to create a bond in an immaculate environment. The resulting joint is incredibly strong, leak-proof, and clean, without the collateral thermal damage that welding can cause to the base metals.

The Deliberate Trade-Off

The path to perfection is never the easiest one. Opting for vacuum furnace technology is a conscious choice that accepts certain trade-offs for an uncompromising result.

The Price of Perfection

Vacuum furnaces represent a significant capital investment. They are complex systems requiring specialized operational knowledge, which adds to the overhead. This cost is accepted because the cost of failure is infinitely higher.

Patience as a Virtue

Achieving a deep vacuum and running a precise thermal cycle is inherently slow. Cycle times are much longer than in atmospheric furnaces. This is the deliberate exchange of speed for certainty. In aerospace, there is no prize for being the fastest to produce a flawed part.

Choosing Your Path in the Void

The specific vacuum process is dictated entirely by the engineering goal.

| Objective | Recommended Process | Primary Benefit |

|---|---|---|

| Create a Flawless Part | Vacuum Investment Casting | Eliminates internal defects and grain boundaries. |

| Enhance an Existing Part | Vacuum Heat Treatment | Optimizes strength, ductility, and stress resistance. |

| Join Complex Components | Vacuum Brazing | Creates strong, pure joints without damaging base metals. |

Mastering these processes is fundamental to modern aerospace. It requires not only an understanding of metallurgy but also access to equipment capable of creating and holding a perfect, controlled environment time and time again. This is where precision-engineered furnace technology becomes the critical enabler for innovation.

At KINTEK, we build the environments where perfection is forged. Our deep R&D and manufacturing expertise allow us to provide a full range of customizable high-temperature systems, including Muffle, Tube, Vacuum, and CVD furnaces, tailored to your exact process requirements. When your mission depends on metallurgical purity and uncompromising performance, you need a partner who understands the engineering of certainty. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

Related Articles

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection

- The Real Reason Your High-Performance Materials Are Failing (And It’s Not the Alloy)

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- From Brute Force to Perfect Control: The Physics and Psychology of Vacuum Furnaces