The Invisible Thief in Heat Treatment

In any thermal process, energy is the primary currency. Yet, we spend much of it fighting an invisible thief: heat loss. It escapes through conduction, radiates away into the environment, and—most significantly—is carried away by the very air inside a conventional furnace.

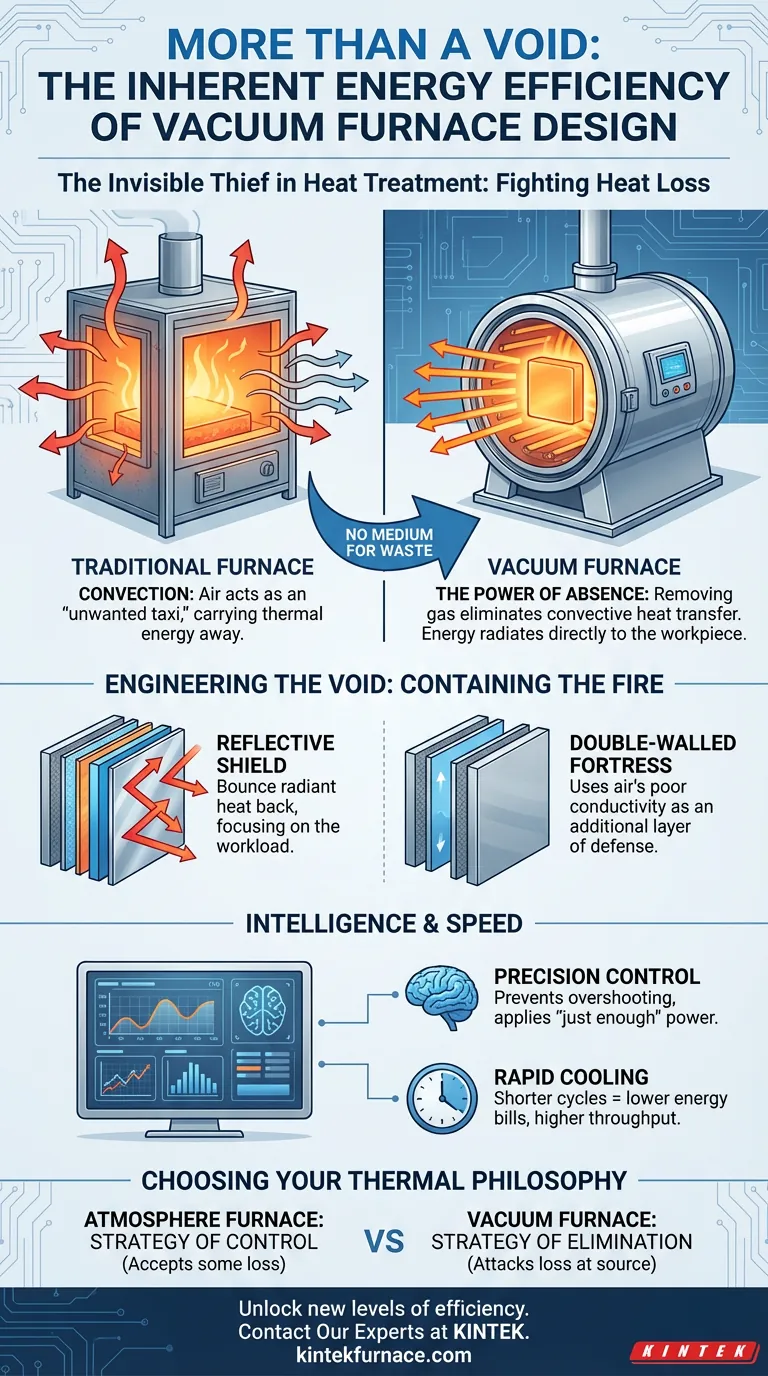

We have a psychological tendency to focus on what we add to a system, like pouring more power into heating elements. But the most elegant engineering solutions often come from what we remove. A vacuum furnace doesn't just heat things in a box; it fundamentally changes the rules of thermal physics by removing the medium for waste.

The Power of Absence

The single greatest source of inefficiency in a traditional furnace is convection. Air or atmosphere gas heats up, circulates, and carries thermal energy away from your workpiece. It's an unwanted taxi service for the BTUs you paid for.

A vacuum furnace fires this taxi service.

By removing nearly all gas molecules, it creates an environment where convective heat transfer is virtually impossible. There is no medium to carry heat away. This simple act of removal has a profound consequence: energy is no longer wasted heating a circulating gas. Instead, it travels from the heating elements to the workpiece through direct radiation—a clean, efficient, line-of-sight transfer.

It's a solution of profound simplicity. The energy goes where you want it, because there's nowhere else for it to go.

Engineering the Void: Containing the Fire

Creating a vacuum is only half the battle. The physical structure of the furnace must be engineered to capitalize on this advantage. The goal is to build a perfect thermal fortress.

A Reflective Shield

With convection gone, radiation and conduction are the remaining paths for heat loss. To combat this, modern vacuum furnaces are lined with multi-layered insulation packages, often made from advanced materials like polycrystalline mullite fiber.

This isn't just insulation; it's a reflective shield. It's designed to bounce radiant heat back into the chamber, keeping it focused on the workload and preventing it from bleeding through the furnace walls.

The Double-Walled Fortress

Some designs go a step further, incorporating double-layer furnace shells. By creating an air gap between an inner and outer wall, they use the poor thermal conductivity of air itself as another layer of defense against heat loss. It's a clever use of simple physics to maximize containment.

Intelligence in Isolation

Efficiency isn't just about preventing loss; it's about intelligent application. Brute force heating is wasteful. Precision is efficient.

This is the role of the furnace's control system. Modern systems act like the furnace's brain, constantly monitoring the temperature and making micro-adjustments to the power output.

This prevents the most common source of energy waste: overshooting the target temperature. The system applies just enough power, at just the right time, to achieve and maintain the perfect thermal profile. This discipline of "just enough" not only saves energy but also improves the quality and consistency of the final product.

The Efficiency of Speed

A final, often overlooked, aspect of efficiency is time. Energy consumption isn't just about kilowatts per hour; it's about total kilowatts per cycle.

Many vacuum furnaces incorporate high-pressure gas quenching systems for rapid cooling. By dramatically shortening the cooling phase, the entire cycle time—from loading to unloading—is reduced.

Running fewer hours per day to process the same number of parts directly translates to lower energy bills and higher operational throughput. Efficiency, in this context, is as much about speed as it is about thermal containment.

Choosing Your Thermal Philosophy

The choice between a vacuum furnace and a traditional atmosphere furnace is a choice of thermal philosophy.

-

Atmosphere Furnace: Manages the environment by filling it with a specific gas. This is a strategy of control. It's a valid and effective approach, but it inherently accepts some level of convective heat loss.

-

Vacuum Furnace: Manages the environment by removing the gas. This is a strategy of elimination. It attacks heat loss at its source, offering a fundamental thermodynamic advantage.

The right choice depends on your goals. For processes demanding the highest levels of part cleanliness and maximum energy efficiency, the vacuum furnace is the superior technical solution. For labs and industries where every second counts, its rapid cycling capabilities offer a compelling operational advantage.

At KINTEK, we specialize in translating these principles into practice. Our deep R&D and manufacturing expertise allow us to build highly efficient Muffle, Tube, Rotary, and advanced Vacuum Furnace systems. Because every process is unique, we provide deep customization to ensure your furnace isn't just a piece of equipment, but a tailored solution designed around your specific thermal philosophy.

To explore how the right furnace design can unlock new levels of efficiency in your work, Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- From Brute Force to Perfect Control: The Physics and Psychology of Vacuum Furnaces

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection

- The Real Reason Your High-Performance Materials Are Failing (And It’s Not the Alloy)

- The Physics of Perfection: How a Vacuum Furnace Creates Order from Chaos