You’ve been here before. Weeks of work have gone into developing a new advanced material. Your chemical formula is sound, the substrate is perfect, and the temperature profile programmed into your furnace is exact. Yet, the result is another failure. The thin film is patchy and brittle. The synthesized powder lacks the required crystalline structure. The data from this run is completely different from the last.

It feels less like science and more like a game of chance. Welcome to one of the most frustrating, and common, challenges in materials science.

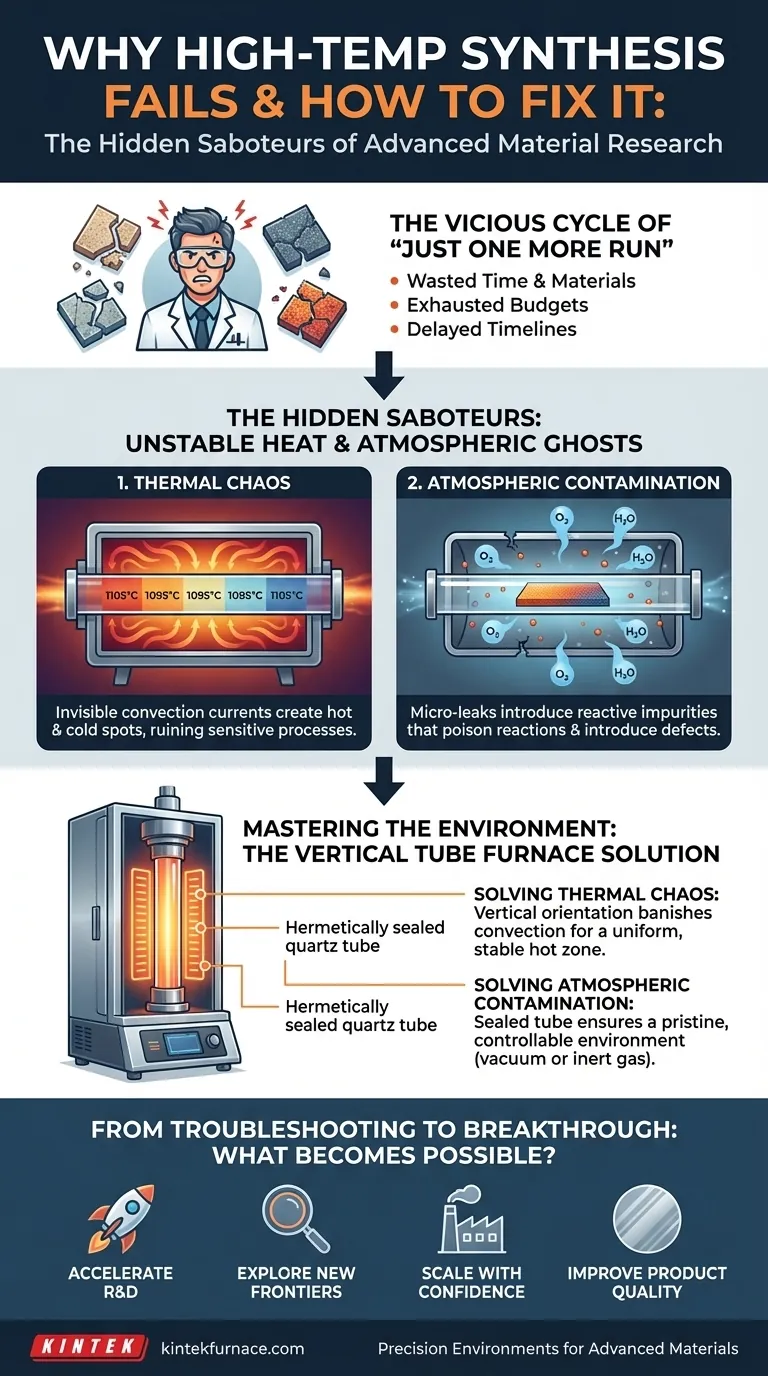

The Vicious Cycle of "Just One More Run"

This inconsistency is a silent project killer in laboratories and R&D centers worldwide. When a high-temperature process fails, we instinctively blame the most visible variables. The troubleshooting checklist begins:

- "Let's tweak the temperature ramp rate."

- "Maybe the precursor gas flow was off by a fraction."

- "Did we calibrate the thermocouple correctly?"

- "Let's just try one more run."

Each attempt consumes expensive precursor materials, precious samples, and even more valuable time. This cycle of trial-and-error doesn't just delay research—it has serious business consequences. Project timelines stretch, R&D budgets are exhausted chasing phantom problems, and the launch of a potentially game-changing product is pushed back, eroding your competitive advantage.

You're trying to fix the recipe, but you're ignoring the oven.

The Hidden Saboteurs: Unstable Heat and Atmospheric Ghosts

The frustrating truth is that in many cases, the problem isn't your process parameters. The problem is that your furnace is physically incapable of creating the stable environment your process demands. Two hidden saboteurs are constantly at work inside a general-purpose furnace:

1. Thermal Chaos

In a standard box furnace or even many horizontal tube designs, heat is not a calm, uniform sea. It’s a turbulent storm of convection currents. This creates invisible hot and cold spots throughout the chamber. While your controller may read a steady 1100°C, one part of your delicate wafer could be experiencing 1105°C while another sits at 1095°C. For sensitive processes like annealing or growing semiconductor layers, this tiny gradient is the difference between a uniform, functional material and a defective, useless one.

2. Atmospheric Contamination

Advanced material synthesis often requires an absolutely pure atmosphere—either a hard vacuum or a specific inert gas. However, many furnaces aren't truly sealed systems. Micro-leaks or the outgassing from chamber walls at high temperatures can introduce trace amounts of oxygen or water vapor. At 1100°C, these contaminants become highly reactive "ghosts" that poison your chemical reactions, introduce defects into your material's crystal lattice, and ruin your results.

This is why your troubleshooting fails. You’re meticulously calibrating your instruments while the fundamental environment—the physics of the heating chamber itself—is actively working against you.

Mastering the Environment: The Physics of a Purpose-Built Furnace

To achieve reproducible, breakthrough results, you don’t just need heat; you need absolute control over the heating environment. This requires a tool designed from the ground up to tame thermal chaos and banish atmospheric ghosts.

This is the core engineering principle behind the vertical tube furnace.

Its design is not an accident; it's a direct solution to these fundamental physical challenges.

-

Solving Thermal Chaos: By orienting the heating chamber vertically, the natural convection currents become stable and predictable. This allows engineers to create an exceptionally uniform, symmetrical "hot zone" that envelops your sample. Every surface, top to bottom, experiences the exact same thermal profile, eliminating the temperature gradients that cause inconsistent results.

-

Solving Atmospheric Contamination: The heart of the furnace is a sealed ceramic or quartz tube. This creates a pristine, hermetically sealed chamber, completely isolated from the outside world. It allows you to pull a deep vacuum to remove contaminants or introduce a continuous flow of ultra-pure process gas with confidence. You gain absolute command over the chemical environment, ensuring your reaction proceeds exactly as designed.

From Troubleshooting to Breakthrough: What Becomes Possible?

When you stop fighting your equipment and start working with a tool designed for environmental control, your focus shifts. The hours once spent on frustrating reruns are now dedicated to genuine innovation.

With a reliable and reproducible process, you can:

- Accelerate R&D: Move confidently from one successful experiment to the next, drastically shortening your development cycle.

- Explore New Frontiers: Work with more sensitive or complex materials that were previously impossible to synthesize reliably.

- Scale with Confidence: Develop a process that can be scaled from the lab to production, knowing that the results will be consistent.

- Improve Product Quality: Create flawless, high-purity thin films for next-generation optics, higher-efficiency semiconductor wafers, or stronger advanced ceramics.

Ultimately, mastering the process environment is the key to unlocking the next generation of materials.

At KINTEK, we don't just sell furnaces; we engineer precision environments. Our vertical tube furnaces are built on a deep understanding of the physical challenges you face, delivering the exceptional uniformity and atmospheric purity required for advanced applications. We know your research is unique, which is why our in-house R&D and manufacturing teams excel at deep customization, tailoring a solution to the precise demands of your project. Stop letting your equipment dictate your results and start achieving the breakthroughs you've been working towards. Contact Our Experts.

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

Related Articles

- Beyond the Checklist: Why Your High-Temperature Furnace Fails (And How to Ensure It Won't)

- Cracked Crucibles, Inconsistent Data? The Post-Heating Step You're Missing

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube

- The Alchemy of Control: Mastering Material Properties with High-Temperature Tube Furnaces

- Beyond the Program: Why Your Sintering Fails and How to Guarantee Uniformity