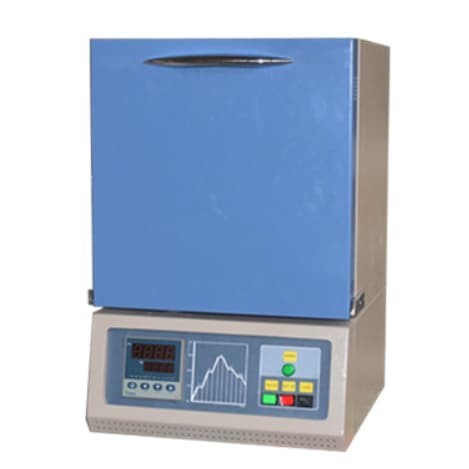

Muffle Furnace

1200℃ Muffle Oven Furnace for Laboratory

Item Number : KT-12M

Price varies based on specs and customizations

- Max. temperature

- 1200℃

- Heating rate

- 0-30℃/min

- Temperature control accuracy

- ±1℃

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

KINTEK KT-12M Series Muffle Furnaces: Precision High-Temperature Performance

The KINTEK KT-12M series muffle furnace is engineered for exceptional performance in demanding laboratory environments. It utilizes high-purity Japanese polycrystalline alumina fiber insulation and embedded Molybdenum-doped resistant heating wire coils, achieving rapid heating speeds up to 30°C per minute and a maximum working temperature of 1200°C. Precise temperature management is ensured by a PID intelligent microprocessor, delivering high accuracy (±1°C) and excellent temperature uniformity (±5°C).

For advanced control and data logging, the KT-12M Pro model features a versatile 7-inch TFT smart touchscreen controller. This allows users to easily set, save, and analyze multiple heating programs, significantly simplifying operation compared to traditional digital controllers and aiding in historical data analysis.

Need a reliable high-temperature solution for your lab? Discuss your requirements with our experts today!

Key Features & Benefits

- Rapid & Precise Heating: Reaches up to 1200°C with a heating rate of up to 30°C/min, controlled by a PID microprocessor for high accuracy and excellent temperature uniformity. Ideal for time-sensitive experiments.

- Superior Insulation & Energy Efficiency: Features Japanese high-purity polycrystalline alumina fiber insulation and a double-shell design with forced air cooling. This minimizes heat loss, ensures a cooler furnace surface for operator safety, and reduces energy consumption.

- Durable & Long-Lasting Construction: Molybdenum-doped resistant heating wire coils are professionally configured to optimize heat radiation properties, ensuring a long service life even under rigorous use.

- Compact & Versatile Design: A small footprint makes it suitable for various lab spaces without compromising on functionality or performance.

- Enhanced User Experience (KT-12M Pro): The 7-inch TFT smart touchscreen controller offers intuitive programming, storage of multiple heating profiles, and easy access to historical data for streamlined workflow and analysis.

- Integrated Safety Interlocks: Ensures operator and equipment safety by automatically shutting off power if the furnace door is opened, an over-temperature condition occurs, or a sensor breaks.

- Contamination-Free Environment: The muffle design isolates materials from direct heat sources and combustion byproducts, crucial for maintaining sample purity.

Technical Specifications

| Furnace model | KT-12M / KT-12M Pro | ||

|---|---|---|---|

| Max. temperature | 1200℃ | ||

| Constant work temperature | 1100℃ | ||

| Furnace tube material (if applicable, typically for tube furnaces) | High purity quartz (confirm if relevant for this muffle) | ||

| Chamber material | Japan alumina fiber | ||

| Heating element | Cr2Al2Mo2 wire coil | ||

| Heating rate | 0-30℃/min | ||

| Temperature sensor | Build in K type thermal couple | ||

| Temperature controller | Digital PID controller (KT-12M) / 7" Touch screen PID controller (KT-12M Pro) | ||

| Temperature control accuracy | ±1℃ | ||

| Temperature uniformity | ±5℃ | ||

| Electric power supply | AC110-220V, 50/60HZ | ||

| Standard Chamber Sizes In Stock | |||

| Chamber size (mm) WxDxH | Effective volume (L) | Chamber size (mm) WxDxH | Effective volume (L) |

| 100x100x100 | 1 | 300x300x400 | 36 |

| 150x150x150 | 3.4 | 400x400x400 | 64 |

| 150x150x200 | 4.5 | 500x500x500 | 125 |

| 200x200x200 | 8 | 600x600x600 | 216 |

| 200x200x300 | 12 | 800x800x800 | 512 |

| Custom designed sizes and volumes are accepted. Inquire for details. | |||

Versatile Applications

KINTEK muffle furnaces are indispensable high-temperature heating devices, providing precise temperature control and isolation from combustion contaminants. This makes them ideal for a wide range of applications across various industrial and laboratory settings:

- Ashing Samples: Crucial for determining residue content in organic and inorganic materials.

- Heat Treatment: Essential for annealing, hardening, and tempering metals and alloys to achieve desired material properties.

- Materials Research: Used to study material behavior at high temperatures and for synthesizing new materials.

- Glass Melting & Fusing: Ideal for applications including technical ceramics and enamel coatings.

- Soldering and Brazing: Provides the necessary high temperatures for creating strong, reliable joints.

- Technical Ceramics: Used in the production and testing of ceramics requiring precise thermal processing.

- Enamel Coatings: Creates durable and aesthetically pleasing enamel coatings on various substrates.

Standard Package

| No. | Description | Quantity |

|---|---|---|

| 1 | Muffle Furnace (KT-12M or KT-12M Pro) | 1 |

| 2 | Thermal block/hearth plate | 1 |

| 3 | Crucible tong | 1 |

| 4 | Heat resistant gloves | 1 pair |

| 5 | Operation manual | 1 |

Optional Setups & Customization

Enhance your furnace's capabilities to meet specific experimental needs:

- Independent furnace temperature monitoring and recording system.

- RS 485 communication port for PC remote control and data exporting.

- Ports for inert gas inlet, exhaust outlet, or observation window.

- Upgrade to touch screen temperature controller (for KT-12M standard model).

We understand that unique experiments require specific solutions. Beyond these standard options, KINTEK excels in deep customization. Contact us to discuss your specific chamber sizes, port configurations, or other specialized requirements.

Advanced Safety Systems

- Over-Current & Over-Temperature Protection: The furnace automatically shuts off power and triggers an alarm if over-current or over-temperature conditions are detected, protecting both the sample and the equipment.

- Thermocouple Failure Detection: A built-in function detects thermocouple breakage or failure; heating stops and an alarm sounds if an issue is identified, preventing uncontrolled heating.

- Power Failure Restart (KT-12M Pro): The furnace can be configured to automatically resume its heating program once power is restored after an outage, ensuring process continuity.

Operating Principle

KINTEK muffle furnaces operate on the principle of indirect heating. Heating elements located outside a sealed ceramic muffle chamber heat the muffle, which in turn radiates heat uniformly to the contents inside. This design ensures precise temperature control and protects samples from direct exposure to heating elements and potential contaminants from combustion, vital for maintaining material purity and integrity.

Ready to Elevate Your Research or Production?

KINTEK's KT-12M series muffle furnaces offer the reliability, precision, and safety your laboratory demands. Whether you need a standard model for routine applications or a fully customized solution for unique experimental challenges, our team is ready to assist.

FAQ

What Are The Main Applications Of A Muffle Furnace?

What Is A Rotating Furnace Used For?

What Are The Key Features Of A Muffle Furnace?

What Are The Main Types Of Rotating Furnaces Available?

How Does A Muffle Furnace Work?

How Does A Rotating Furnace Work?

What Are The Advantages Of Using A Muffle Furnace?

What Are The Advantages Of Using A Rotating Furnace?

What Types Of Muffle Furnaces Are Available?

What Safety Features Are Included In Rotating Furnaces?

Can Rotating Furnaces Be Customized For Specific Applications?

4.8 / 5

This furnace heats up incredibly fast! Perfect for urgent lab work. Highly recommend!

4.9 / 5

The build quality is outstanding. It feels like it will last for years. Worth every penny!

4.7 / 5

Delivery was lightning fast! The furnace works like a dream. So impressed!

4.9 / 5

Precision and performance are top-notch. A must-have for any serious lab.

4.8 / 5

The temperature control is so accurate. Makes my experiments a breeze!

4.7 / 5

Durable and reliable. It’s been a game-changer for our research team.

4.9 / 5

The design is sleek and modern. It’s also surprisingly energy-efficient!

4.8 / 5

Arrived in perfect condition. The furnace exceeds all expectations. Love it!

4.9 / 5

Incredible value for the price. It’s like having a premium tool without the premium cost.

4.7 / 5

The customer service was excellent, and the product is even better. 10/10!

4.8 / 5

So easy to use! The interface is intuitive, and the results are consistent.

4.9 / 5

This furnace is a beast! Handles high temperatures with ease. Super reliable.

4.7 / 5

The packaging was secure, and setup was a breeze. Very happy with my purchase!

4.8 / 5

The thermal uniformity is impressive. Perfect for precise lab applications.

4.9 / 5

A fantastic investment. It’s made our lab work so much more efficient.

4.7 / 5

The furnace arrived ahead of schedule. Performance is flawless. Highly satisfied!

4.8 / 5

The craftsmanship is exceptional. It’s clear this was made with care and expertise.

4.9 / 5

The advanced features are a huge plus. It’s like having a lab assistant!

4.8 / 5

Perfect for high-temperature applications. It’s reliable and efficient. Love it!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory Muffle Oven Furnace with Bottom Lifting

Boost lab efficiency with KT-BL Bottom Lifting Furnace: precise 1600℃ control, superior uniformity, and enhanced productivity for material science and R&D.

1400℃ Muffle Oven Furnace for Laboratory

KT-14M Muffle Furnace: Precision 1400°C heating with SiC elements, PID control, and energy-efficient design. Ideal for labs.

1800℃ High Temperature Muffle Oven Furnace for Laboratory

KINTEK Muffle Furnaces: Precision 1800°C heating for labs. Energy-efficient, customizable, with PID control. Ideal for sintering, annealing, and research.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Vacuum Induction Melting Furnace

Explore KINTEK's Vacuum Induction Melting Furnace for high-purity metal processing up to 2000℃. Customizable solutions for aerospace, alloys, and more. Contact us today!

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!

600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

600T Vacuum Induction Hot Press Furnace for precise sintering. Advanced 600T pressure, 2200°C heating, vacuum/atmosphere control. Ideal for research & production.

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

Vacuum Heat Treat Sintering and Brazing Furnace

KINTEK Vacuum Brazing Furnaces deliver precision, clean joints with superior temperature control. Customizable for diverse metals, ideal for aerospace, medical, and thermal applications. Get a quote!

Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

Compact vacuum tungsten wire sintering furnace for labs. Precise, mobile design with superior vacuum integrity. Ideal for advanced material research. Contact us!

Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

KINTEK's Vacuum Molybdenum Wire Sintering Furnace excels in high-temperature, high-vacuum processes for sintering, annealing, and material research. Achieve precise 1700°C heating with uniform results. Custom solutions available.

Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

KINTEK's Vacuum Pressure Sintering Furnace offers 2100℃ precision for ceramics, metals, and composites. Customizable, high-performance, and contamination-free. Get a quote now!

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

1700℃ High Temperature Muffle Oven Furnace for Laboratory

KT-17M Muffle Furnace: High-precision 1700°C lab furnace with PID control, energy efficiency, and customizable sizes for industrial & research applications.

Vacuum Heat Treat Furnace with Ceramic Fiber Liner

KINTEK's Vacuum Furnace with Ceramic Fiber Lining offers precise high-temperature processing up to 1700°C, ensuring uniform heat distribution and energy efficiency. Ideal for labs and production.

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

KINTEK RF PECVD System: Precision thin-film deposition for semiconductors, optics & MEMS. Automated, low-temperature process with superior film quality. Custom solutions available.

Vertical Laboratory Quartz Tube Furnace Tubular Furnace

Precision KINTEK Vertical Tube Furnace: 1800℃ heating, PID control, customizable for labs. Ideal for CVD, crystal growth & materials testing.

Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

Ultra-High Vacuum Flange Aviation Plug Connector for aerospace & labs. KF/ISO/CF compatible, 10⁻⁹ mbar airtight, MIL-STD certified. Durable & customizable.

Related Articles

The Microwave Sintering Trap: Why the 'Best' Furnace Might Be the Wrong Choice for Your Lab

Is microwave sintering always the best choice? Discover the hidden costs and learn a smarter way to select the right high-temperature furnace for your lab.

Beyond the Void: The Controlled Universe Inside a High Vacuum Furnace

A high vacuum furnace isn't empty; it's a controlled universe. Learn how it masters chemistry and thermal physics for superior materials.

The Controlled Void: Mastering Material Purity with Vacuum Furnaces

Vacuum furnaces achieve material purity not just with heat, but by removing the reactive atmosphere that causes oxidation and contamination.

Purity Under Pressure: The Materials Science of a Vacuum Furnace Hot Zone

Explore the engineering trade-offs between molybdenum and graphite in a vacuum furnace's hot zone, revealing how material choices dictate process purity and performance.

The Unseen Battle: Containing Molten Magnesium and the Quest for Purity

Discover why corundum's inertness and thermal stability make it the only choice for preventing contamination in high-temperature metal experiments.

Why Your High-Purity Metal Distillation Fails: The Crucible Contamination You Can’t See

Frustrated by inconsistent metal purity? Discover the hidden chemical reaction in your crucible that's sabotaging your results and how to solve it.