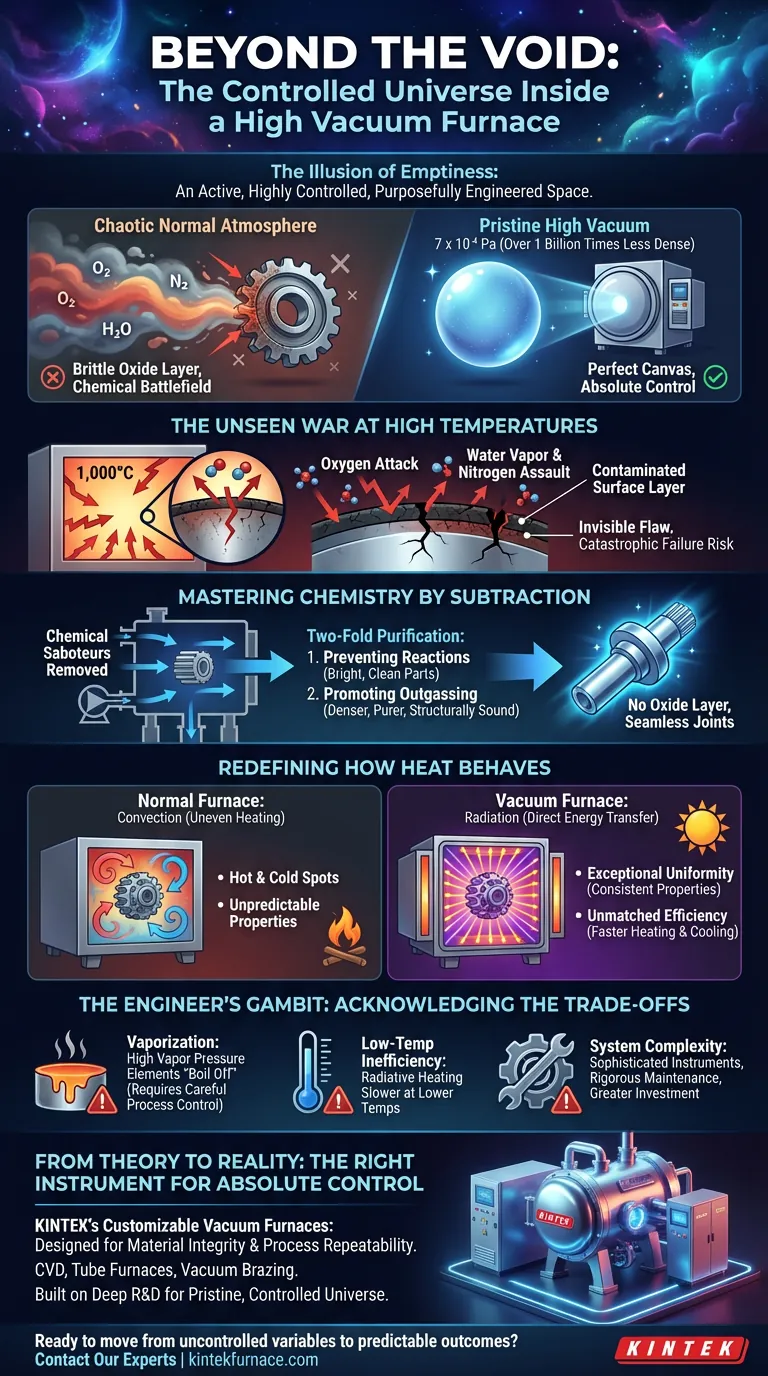

The Illusion of Emptiness

We tend to think of a vacuum as nothing—an empty, passive space. This is a profound misunderstanding.

The environment inside a high vacuum furnace is one of the most active, highly controlled, and purposefully engineered spaces in modern materials science. Its purpose is not to create nothing, but to create a perfect canvas, free from the chaotic, reactive variables of our normal atmosphere.

It's about gaining absolute control.

The Unseen War at High Temperatures

Imagine designing a critical component for a jet engine. Every curve is optimized, every gram of its advanced alloy is specified for strength under extreme stress. Now, you place it in a conventional furnace for heat treatment.

At 1,000°C, the atmosphere becomes a chemical battlefield. Oxygen molecules, harmless at room temperature, aggressively attack the component's surface, forming a brittle oxide layer—an invisible flaw that could seed a catastrophic failure. Water vapor and nitrogen join the assault, altering the material's surface chemistry in unpredictable ways.

You didn’t just heat the part; you contaminated it. This is the fundamental problem a vacuum furnace solves.

Mastering Chemistry by Subtraction

A high vacuum furnace's primary function is to systematically remove these chemical saboteurs. By pumping the chamber down to pressures as low as 7 x 10⁻⁴ Pascals (Pa)—over a billion times less dense than the air we breathe—it creates an environment so pure that these reactions simply cannot happen.

The Two-Fold Purification

This extreme environment does more than just prevent contamination. It actively purifies.

- Preventing Reactions: With virtually no oxygen or water vapor, parts emerge from the furnace bright and clean. This is essential for processes like high-purity brazing, where even a microscopic oxide layer can prevent a strong, seamless joint from forming.

- Promoting Outgassing: The low pressure creates a powerful incentive for trapped impurities within the material—like dissolved hydrogen or other gases—to escape. The vacuum literally pulls them out, leading to a denser, purer, and more structurally sound final product.

It’s the art of achieving perfection by taking things away.

Redefining How Heat Behaves

Removing the atmosphere doesn't just change the chemistry; it fundamentally rewrites the rules of thermal physics.

In a normal furnace, air currents (convection) create hot and cold spots, leading to uneven heating. Think of the swirling, unpredictable heat from a campfire.

In a vacuum, heat transfer occurs almost entirely through radiation, the same way the sun warms the Earth. It's a direct, line-of-sight transfer of energy.

The Power of Radiative Heating

- Exceptional Uniformity: Every surface of a complex part, from its thick core to its delicate edges, receives the same amount of energy. This ensures consistent, predictable metallurgical properties across the entire component.

- Unmatched Efficiency: With no air to heat up first, energy is focused directly on the workpiece. This allows for faster heating cycles and, when complete, rapid and uniform cooling through controlled backfilling with an inert gas (gas quenching).

This level of thermal control is impossible to achieve in a standard atmosphere.

The Engineer's Gambit: Acknowledging the Trade-offs

This pursuit of perfection comes with its own set of challenges, which any serious engineer must manage. A high vacuum environment is a powerful tool, not a magic bullet.

- Vaporization: At very high temperatures and low pressures, certain elements with high vapor pressures (like chromium in some steels) can "boil" off and be removed by the vacuum pump, altering the alloy's composition. This requires careful process control.

- Low-Temp Inefficiency: Radiative heating is less effective at lower temperatures (below ~600°C). This can sometimes slow the initial phase of a cycle compared to a convection furnace.

- System Complexity: High vacuum systems are sophisticated instruments. They demand rigorous maintenance and operational expertise, representing a greater investment in both capital and knowledge.

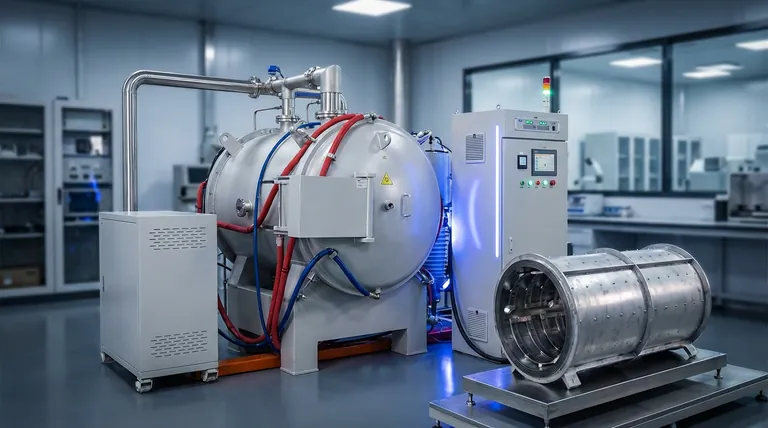

From Theory to Reality: The Right Instrument for Absolute Control

Choosing a vacuum furnace is a declaration that you prioritize material integrity and process repeatability above all else. It's a decision to eliminate variables, not just accommodate them.

Achieving this requires more than just a steel box and a pump. It requires a system engineered for your specific application—one that can maintain a deep vacuum, deliver uniform radiative heat, and manage the inherent trade-offs of the process.

This is where expert engineering and manufacturing become critical. KINTEK's customizable vacuum furnaces are designed precisely for this level of control. Whether for CVD systems, tube furnaces, or specialized vacuum brazing applications, our systems are built on a foundation of deep R&D to provide the pristine, controlled universe your most demanding materials require.

If you're ready to move from uncontrolled variables to predictable, superior outcomes, we can help you design the precise environment your materials demand. Contact Our Experts

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- Mastering the Void: How Custom Vacuum Furnaces Forge the Future of Materials

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design