The Hidden Battle Inside Every Component

Imagine a single turbine blade inside a jet engine. At 30,000 feet, it spins thousands of times per minute while enduring temperatures that would melt steel. Its survival isn't a matter of chance; it's the result of microscopic perfection engineered deep within its crystalline structure.

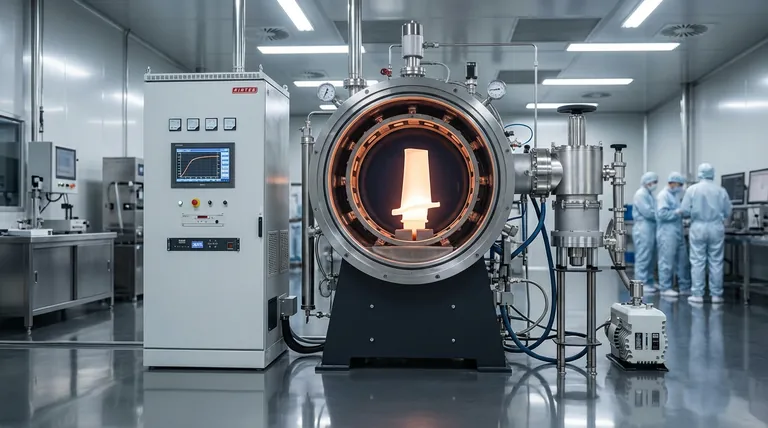

This perfection is forged in a controlled environment of extreme heat and pristine vacuum. But for engineers pushing the boundaries of what's possible, a standard, off-the-shelf furnace often represents a compromise. It's a versatile tool, but it's not a master instrument.

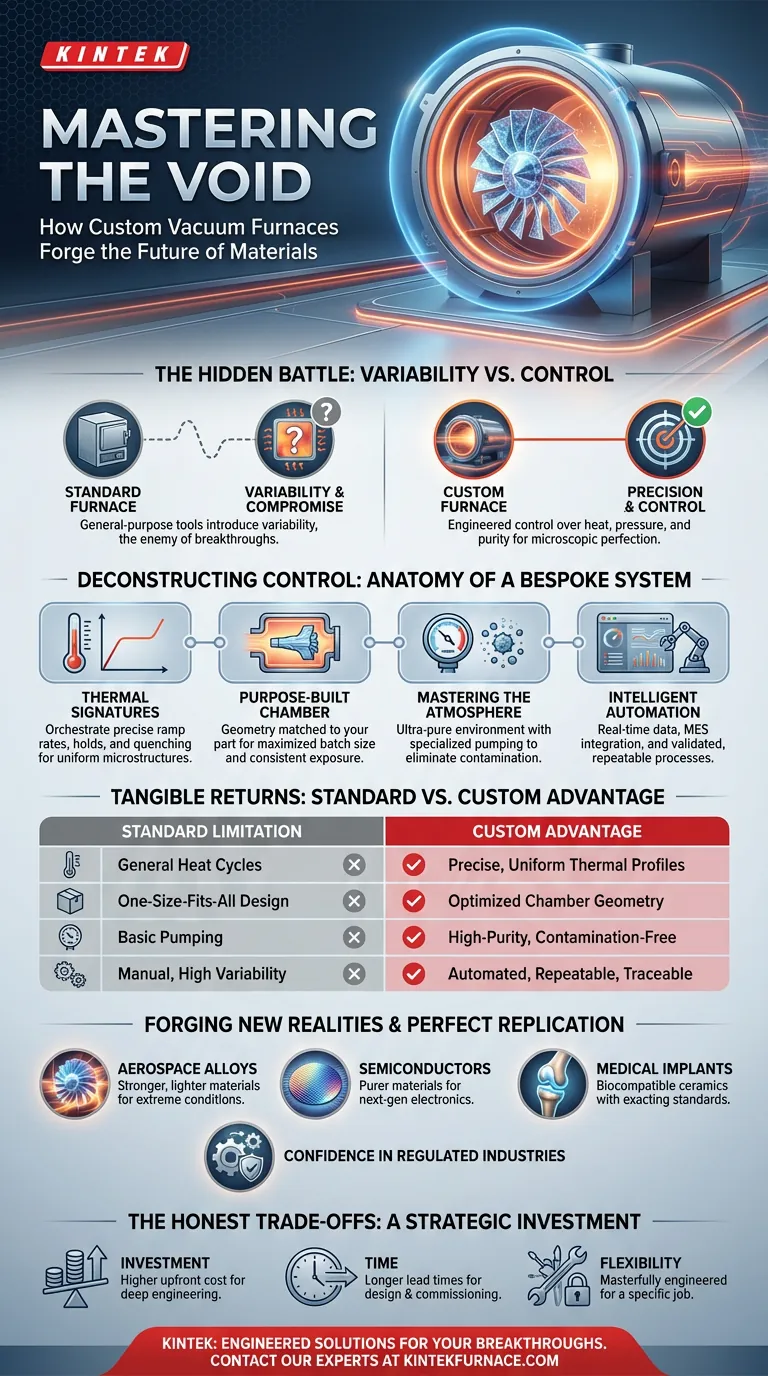

The pursuit of next-generation materials is fundamentally a battle for control—control over heat, pressure, and purity. Settling for a "good enough" tool in this battle introduces variability, and variability is the enemy of breakthroughs.

Deconstructing Control: The Anatomy of a Bespoke Furnace

A custom-designed furnace isn't just a bigger or hotter box. It’s a purpose-built system where every component is a deliberate answer to a specific manufacturing challenge. It's about replacing approximation with intention.

Beyond Temperature: Engineering Thermal Signatures

A standard furnace gives you a temperature. A custom furnace allows you to orchestrate a thermal signature.

This means defining the precise ramp rates, holds, and quenching profiles needed to achieve a specific microstructure. For complex geometries, it means engineering heating elements and insulation for absolute thermal uniformity, ensuring one side of a component isn't living in a different thermal reality than the other.

The Chamber as a Purpose-Built Universe

Why force a unique component into a generic chamber?

Customization rethinks the chamber's very geometry to match your part, maximizing batch size and ensuring consistent exposure. The materials themselves are chosen to eliminate contamination risks—a critical factor in processes like vacuum arc melting where parts-per-million impurities can lead to catastrophic failure.

Mastering the Atmosphere (Or Its Absence)

In advanced processes like vacuum sintering, the real work isn't just about adding heat; it's about what you remove. The invisible enemy is atmosphere—oxygen, nitrogen, and water vapor.

A custom furnace provides mastery over this void. It’s designed with the specific pumping systems, gas management, and partial pressure controls needed to create an ultra-pure environment. This isn't just a feature; it's the foundation for achieving near-theoretical density and strength in the final product.

From Manual Tweaks to Intelligent Systems

Human variability is the final frontier of process control. Customization addresses this by integrating intelligent automation directly into the workflow.

This goes far beyond simple temperature programs. It includes automated loading, real-time data logging for traceability, and seamless integration with a facility's Manufacturing Execution System (MES). The system doesn't just run a cycle; it executes a validated, repeatable process, removing the guesswork and ensuring every run is identical.

The Tangible Returns on Precision

This obsession with control isn't just an academic exercise. It translates directly into measurable gains in performance, reliability, and efficiency.

| Feature | Standard Furnace Limitation | Custom Furnace Advantage |

|---|---|---|

| Thermal Profile | General-purpose heating cycles | Precise, uniform heat for targeted microstructures |

| Chamber Design | One-size-fits-all | Optimized for part geometry and batch efficiency |

| Vacuum Control | Basic pumping capabilities | High-purity environment, eliminating contamination |

| Process Control | Manual operation, high variability | Automated, fully repeatable, and traceable runs |

Forging New Material Realities

By fine-tuning heat, vacuum, and even mechanical pressure (as in vacuum hot pressing), custom furnaces create materials with properties that were once only theoretical. This is how we get stronger, lighter alloys for aerospace, purer silicon for next-generation semiconductors, and biocompatible ceramics for medical implants.

The Psychology of Perfect Replication

In regulated industries, repeatability isn't just about quality; it's about confidence. When every component must meet exacting standards, the certainty provided by a fully automated, custom-tuned process is invaluable. It transforms manufacturing from a series of discrete events into a continuous, predictable, and validated system.

The Honest Trade-Offs: A Calculated Investment

A custom furnace is a scalpel, not a multi-tool. Its power lies in its specificity, which comes with clear trade-offs.

- Investment: The upfront cost is significantly higher due to the deep engineering and specialized fabrication involved.

- Time: Lead times are longer, requiring close collaboration from design through commissioning.

- Flexibility: It is masterfully engineered for one job, making it less adaptable if your production needs pivot dramatically.

The decision is not about buying a piece of equipment. It's a strategic investment in mastering a critical process. It's a declaration that for your most important work, "good enough" is no longer good enough.

At KINTEK, we specialize in translating these complex challenges into engineered solutions. Backed by expert R&D and manufacturing, we offer a range of customizable high-temperature systems, including Muffle, Tube, Vacuum, and CVD furnaces, designed to provide the unparalleled control your process demands. We build the master instruments that enable your breakthroughs.

To discuss how a tailored thermal solution can solve your most advanced manufacturing challenges, Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

Related Articles

- The Most Important Number in a Vacuum Furnace Isn't Its Temperature

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Architecture of Purity: Deconstructing the Vacuum Furnace System

- In Pursuit of Purity: The Silent Power of the Vacuum Furnace

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection