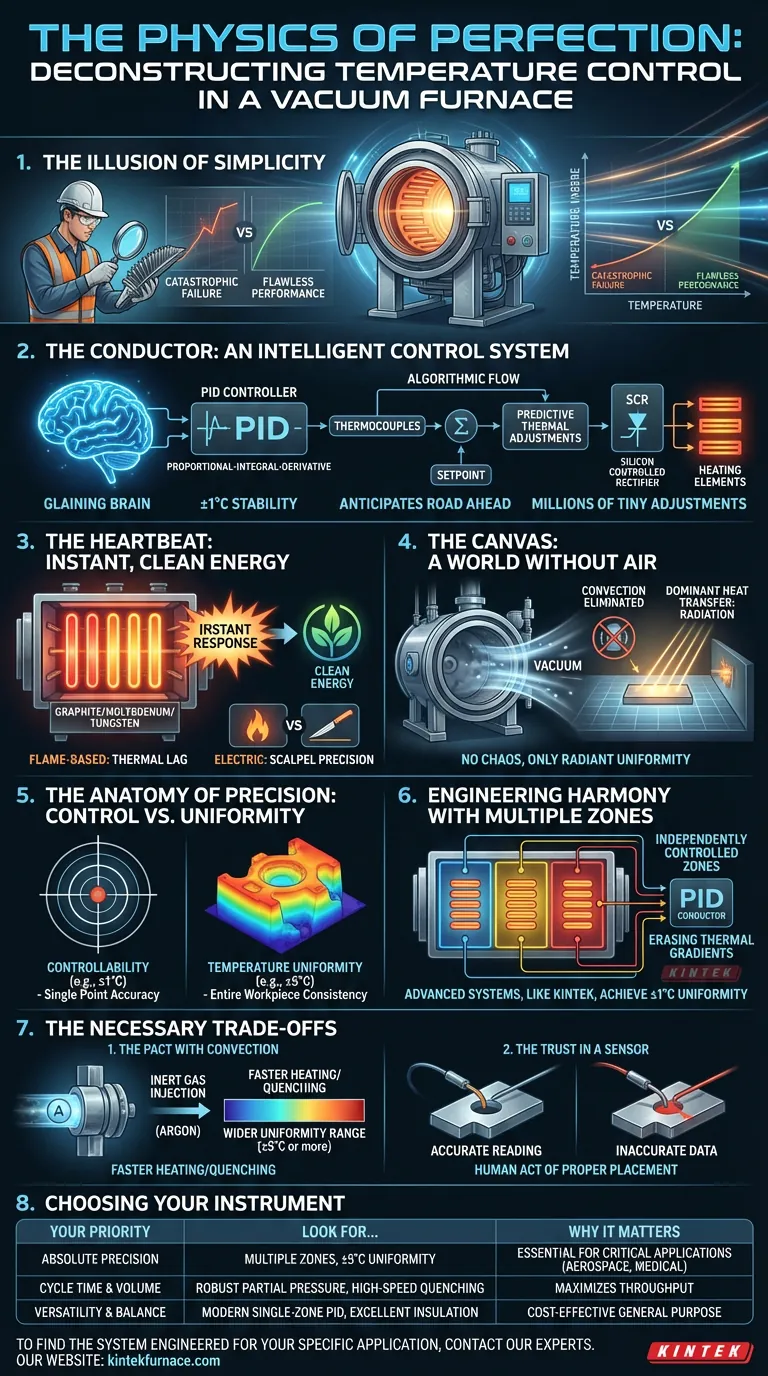

The Illusion of Simplicity

An engineer inspects a turbine blade just out of the furnace. To the untrained eye, it’s just a piece of metal. But to the engineer, it’s a component where a few degrees Celsius during the brazing process separates flawless performance from catastrophic failure at 30,000 feet.

Achieving this level of certainty isn’t about a better thermostat. It’s about mastering a complex physical environment. Precise temperature control in a vacuum furnace is not the result of a single component, but a three-part symphony between a digital brain, an electric heart, and the physics of empty space.

The Conductor: An Intelligent Control System

At the center of the system is the PID (Proportional-Integral-Derivative) controller. Thinking of it as a simple cruise control system doesn't do it justice. It's more like an expert driver, not just maintaining speed but anticipating the road ahead.

The PID controller constantly measures the temperature with thermocouples and compares it to the desired setpoint. But instead of just turning the heat on or off, its algorithm predicts thermal overshoot and undershoot. It then delicately modulates power to the heating elements through an SCR (Silicon Controlled Rectifier), making millions of tiny adjustments to keep the temperature locked in, often with a stability of ±1°C. It’s a constant, vigilant feedback loop.

The Heartbeat: Instant, Clean Energy

Unlike flame-based systems with their thermal lag and impurities, a vacuum furnace’s heart is electric. The heating elements, typically crafted from graphite, molybdenum, or tungsten to withstand temperatures up to 3,000°C, provide power that is both immense and incredibly responsive.

When the PID conductor demands a change, the response is instantaneous. There is no thermal inertia from burning fuel. This gives the system a level of finesse that is simply impossible with combustion. It’s the difference between a sledgehammer and a scalpel—pure, clean, and precisely delivered energy.

The Canvas: A World Without Air

The most profound element of control is the vacuum itself. By evacuating the chamber, we remove the chaotic variable of air.

In a normal atmosphere, heat transfer is dominated by convection—unpredictable currents that create hot and cold spots, like turbulence in water. In a vacuum, convection is eliminated. Heat moves almost exclusively through radiation, a direct, line-of-sight path from the heating element to the part. This creates an incredibly stable and uniform heating environment, a perfect canvas on which to perform a precise thermal process.

The Anatomy of Precision: Control vs. Uniformity

In the world of thermal processing, "control" and "uniformity" are two different, and often misunderstood, concepts.

-

Controllability is how well the furnace holds the temperature at a single point (where the sensor is). Think of it as a sniper hitting the exact center of a target. Modern systems can achieve a controllability of ±1°C.

-

Temperature Uniformity is how consistent the temperature is across the entire workpiece. This is the true challenge. It's about ensuring every edge, curve, and internal section of the part sees the same temperature, accounting for natural hot and cold spots in the chamber. A typical specification might be ±5°C.

Engineering Harmony with Multiple Zones

Achieving exceptional uniformity—the kind required for medical implants or aerospace components—requires a more sophisticated approach. High-performance furnaces divide the heating chamber into multiple, independently controlled zones.

Each zone has its own power supply and thermocouple, allowing the PID controller to act like a conductor leading different sections of an orchestra. It can intelligently send more energy to a cooler zone near the door and less to a hotter zone in the rear, actively erasing thermal gradients across the workload. This level of granular management is a hallmark of advanced systems, like the customizable vacuum furnaces engineered by KINTEK, where achieving uniformity down to ±1°C is a core design principle for critical applications.

The Necessary Trade-offs

Perfection is always balanced against practicality. Two key trade-offs define the operational reality of a vacuum furnace.

1. The Pact with Convection

For faster heating or cooling (quenching), an inert gas like argon is introduced at a low pressure. This reintroduces convection, dramatically speeding up the thermal cycle. The trade-off is a loss of absolute uniformity, which might widen to ±5°C or more. This isn't a flaw; it's a strategic choice, prioritizing throughput when absolute uniformity is less critical.

2. The Trust in a Sensor

The entire system is only as good as the data it receives. A furnace's controller may read a temperature with pinpoint accuracy (e.g., ±1.5°C of the thermocouple's actual reading), but if that thermocouple isn't placed correctly on or near the part, the controller is mastering a temperature the part isn't actually experiencing. Process integrity relies on the simple, human act of proper sensor placement.

Choosing Your Instrument

The right furnace is defined by the demands of the application. The choice is a reflection of your process philosophy.

| Your Priority | Look For... | Why It Matters |

|---|---|---|

| Absolute Precision | Multiple, independently controlled heat zones and a uniformity spec of ±5°C or better. | Essential for aerospace, medical, and advanced R&D where material properties are paramount. |

| Cycle Time & Volume | Robust partial pressure and high-speed gas quenching systems. | Maximizes throughput for production environments by reducing heating/cooling times. |

| Versatility & Balance | A well-built single-zone furnace with a modern PID controller and excellent insulation. | Offers a cost-effective solution for general-purpose heat treating and lab work. |

Understanding this system—the conductor, the heartbeat, and the canvas—is the key to unlocking true material potential. For processes that leave no room for error, the right furnace is not just equipment; it's a partner in innovation. To find the system engineered for your specific application, Contact Our Experts.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

Related Articles

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Architecture of Purity: Deconstructing the Vacuum Furnace System

- Beyond the Void: A Framework for Choosing Your Vacuum Furnace

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection

- The Physics of Perfection: How Vacuum Furnaces Redefine Material Integrity