A metallurgist develops a new turbine blade alloy. The goal is impossible strength at impossible temperatures. In the final stage of processing, the alloy enters a vacuum furnace. The success of the entire project—millions in research, years of work—doesn't depend on how hot the furnace gets, but on how perfectly empty it can be.

This isn't just a story about heating metal. It's a story about the pursuit of absolute control over an environment. The psychology of high-stakes material science reveals a fundamental truth: a vacuum furnace isn't a simple oven. It's a precision instrument for manipulating nothingness.

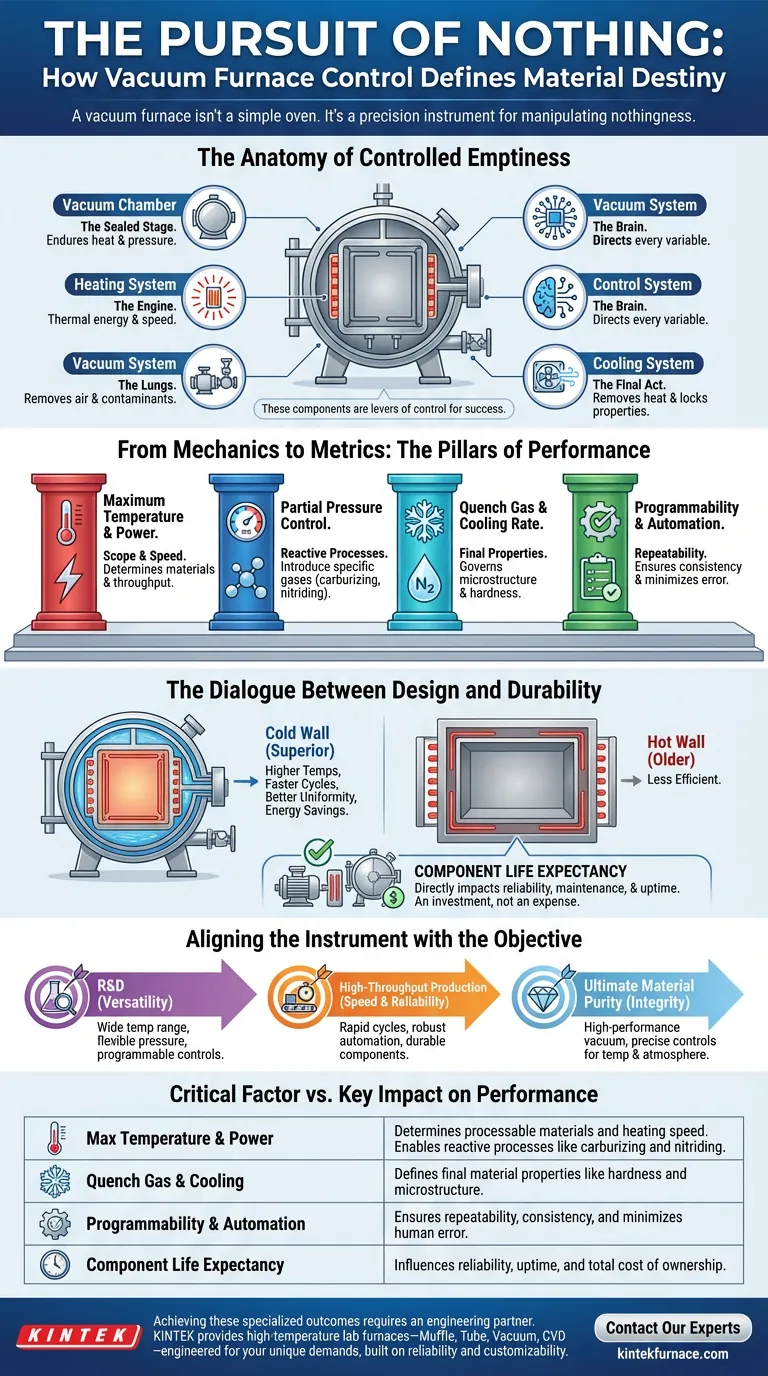

The Anatomy of Controlled Emptiness

To command the void, you must first understand its architecture. A vacuum furnace is an orchestra of integrated systems, each performing a critical function to create a pristine, reactive environment.

- The Vacuum Chamber: The sealed stage where the process unfolds. It must endure immense heat from within and the crushing pressure of the atmosphere from without.

- The Heating System: The engine of transformation. Its elements deliver thermal energy, and their design dictates the speed, uniformity, and upper limit of the heat treatment.

- The Vacuum System: A series of pumps that act as the lungs, methodically removing air and contaminants to create the vacuum—the foundation of the entire process.

- The Control System: The brain of the operation. It directs every variable with digital precision, ensuring the complex thermal recipe is followed flawlessly every single time.

- The Cooling System: The final act. It removes heat at a controlled rate, often using inert gases, to lock in the material's desired final properties.

These components aren't just parts. They are levers of control. Their performance translates directly into the factors that determine success or failure.

From Mechanics to Metrics: The Pillars of Performance

The quality of a vacuum process hinges on a handful of critical operational factors. Mastering them is the difference between creating a standard metal and engineering a superalloy.

Pillar 1: Maximum Temperature & Power

This is the most fundamental metric. The furnace's maximum operating temperature determines its scope—the types of materials it can process and the metallurgical transformations it can induce. The power load dictates how quickly it can reach that temperature, a key factor in throughput and efficiency.

Pillar 2: Partial Pressure Control

A truly advanced system does more than just remove air. It allows for the precise introduction of specific gases at a controlled partial pressure. This capability is essential for reactive processes like vacuum carburizing or nitriding, where the atmosphere itself becomes an ingredient in the material's final composition. It's the art of adding a little something back into the nothingness.

Pillar 3: Quench Gas & Cooling Rate

Heating is only half the battle. The final microstructure, hardness, and strength of a material are set during cooling. The choice of quench gas (like nitrogen or argon) and the pressure at which it floods the chamber governs the cooling rate. This is the rapid, controlled finale that freezes the desired atomic structure in place.

Pillar 4: Programmability & Automation

Human intuition is valuable, but consistency belongs to machines. A sophisticated control system that allows for the programming and automation of the entire cycle—from pump-down to heating ramps to quenching—is the cornerstone of repeatability. It eliminates variability and ensures that the 100th batch is identical to the first.

The Dialogue Between Design and Durability

Not all furnaces are created equal. The underlying design philosophy has profound implications for performance and long-term reliability.

Cold wall furnaces, where heating elements reside inside a water-cooled chamber, offer superior performance. They can achieve higher temperatures, faster thermal cycles, and better temperature uniformity compared to older hot wall designs. This efficiency isn't just about speed; it's about energy savings and greater process control.

But the most overlooked factor is the life expectancy of core components. The quality of the heating elements, vacuum pumps, and chamber integrity directly impacts reliability, maintenance costs, and operational uptime. Investing in durability isn't an expense; it's a strategic decision to ensure the instrument is always ready.

Aligning the Instrument with the Objective

The "best" furnace is the one that aligns perfectly with your primary goal. The choice is a reflection of your priorities.

- For pure research & development, you need maximum versatility: a wide temperature range, flexible partial pressure options, and a highly programmable control system.

- For high-throughput production, you need speed and rock-solid reliability: rapid heating/cooling cycles, robust automation, and durable components built for continuous operation.

- For achieving ultimate material purity, you need vacuum integrity above all else: a high-performance vacuum system and precise controls for both temperature and atmosphere.

| Critical Factor | Key Impact on Performance |

|---|---|

| Max Temperature & Power | Determines processable materials and heating speed. |

| Partial Pressure Control | Enables reactive processes like carburizing and nitriding. |

| Quench Gas & Cooling | Defines final material properties like hardness and microstructure. |

| Programmability & Automation | Ensures repeatability, consistency, and minimizes human error. |

| Component Life Expectancy | Influences reliability, uptime, and total cost of ownership. |

Achieving these specialized outcomes requires more than an off-the-shelf product. It requires an engineering partner.

Backed by expert R&D and manufacturing, KINTEK provides high-temperature lab furnaces—including Muffle, Tube, Vacuum, and CVD systems—engineered for precisely these challenges. Our systems are built on a foundation of reliability and precision, but their true strength lies in their customizability. We tailor each furnace to the unique demands of your process, ensuring your instrument is perfectly aligned with your objective.

When your work depends on the absolute control of a thermal environment, you need a system built for that purpose. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection