The Illusion of Efficiency in Batch Processing

In manufacturing, we often mistake activity for progress. A traditional batch furnace feels productive. The door opens, a new load goes in, the cycle runs, the parts come out. It’s a tangible, observable loop of work.

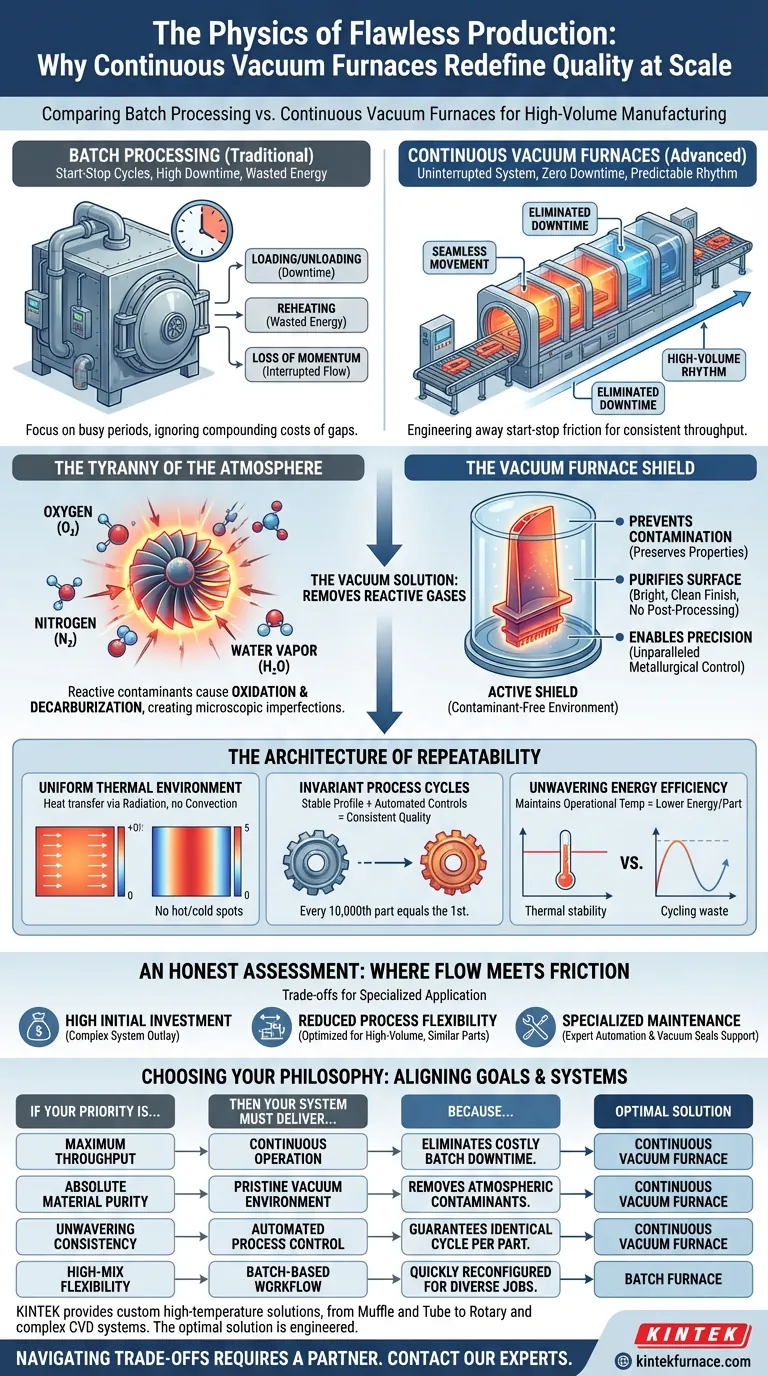

But the true cost of this model lies in the silence between cycles. The downtime for loading and unloading. The massive energy wasted reheating the furnace from a cooled state. The loss of production momentum. This is the psychological trap of batch work: we focus on the busy periods and ignore the compounding cost of the gaps.

Manufacturing as a Continuous Flow

A continuous vacuum furnace operates on a different philosophy. It isn't a series of discrete jobs; it is an uninterrupted, flowing system.

Parts move seamlessly through dedicated heating and cooling zones on an automated conveyor. This design doesn't just reduce downtime—it eliminates it. By engineering away the start-stop friction inherent in batch processing, it establishes a predictable, high-volume rhythm. This makes it the backbone of industries like automotive and electronics, where consistent throughput is not just a goal, but a necessity.

The Tyranny of the Atmosphere

Imagine a critical aerospace component, like a turbine blade spinning thousands of times per minute. Its structural integrity is absolute. Yet, when heated in the presence of normal air, its very surface is under attack.

Oxygen, nitrogen, and water vapor are not inert; they are reactive contaminants. At high temperatures, they cause oxidation and decarburization, creating microscopic imperfections that can become catastrophic failure points. The atmosphere becomes a source of invisible, uncontrolled variables.

A vacuum furnace conquers this problem. It doesn't just create empty space; it creates an active shield. By removing reactive gases, it ensures the material's surface and internal structure remain pristine.

- It Prevents Contamination: The material's chemical composition and mechanical properties are perfectly preserved.

- It Purifies the Surface: Processes like degassing pull trapped impurities out of the metal, resulting in a bright, clean finish that often requires no post-processing.

- It Enables Precision: With atmospheric interference gone, metallurgical properties like strength, hardness, and ductility can be developed with unparalleled precision.

The Architecture of Repeatability

Beyond purity, the system is an architecture of control. It turns the art of heat treatment into a repeatable science.

Uniform Thermal Environment

In a vacuum, heat transfer occurs primarily through radiation, not convection. This promotes exceptionally uniform temperature distribution across the entire workpiece, eliminating the hot and cold spots that can plague conventional furnaces.

Invariant Process Cycles

The stable thermal profile and automated controls guarantee that the ten-thousandth part undergoes the exact same process as the first. This high level of invariance is critical for quality assurance and meeting the stringent certification requirements of the aerospace and medical industries.

Unwavering Energy Efficiency

While a batch furnace repeatedly wastes energy on thermal cycling, a continuous furnace maintains its operational temperature. This thermal stability results in significantly lower energy consumption per part, a crucial economic advantage at scale.

An Honest Assessment: Where Flow Meets Friction

This technology is a specialized instrument, not a universal solution. Its power comes with clear trade-offs.

- High Initial Investment: Continuous vacuum systems are complex and require a significant capital outlay compared to batch furnaces. It is an investment in a manufacturing system, not just a machine.

- Reduced Process Flexibility: They are optimized for high-volume runs of similar parts. They are ill-suited for high-mix, low-volume job shops that need to change temperature profiles and cycle times frequently.

- Specialized Maintenance: The sophisticated automation and vacuum seals demand a higher level of expert maintenance to ensure reliability and uptime.

Choosing Your Philosophy: Throughput, Purity, or Flexibility?

The right furnace is the one that aligns with your core operational goals. The decision isn't just technical; it's strategic.

| If Your Priority Is... | Then Your System Must Deliver... | Because... |

|---|---|---|

| Maximum Throughput | Continuous Operation | It completely eliminates costly batch downtime. |

| Absolute Material Purity | A Pristine Vacuum Environment | It removes atmospheric contaminants that cause defects. |

| Unwavering Consistency | Automated Process Control | It guarantees every part sees an identical cycle. |

| High-Mix Flexibility | A Batch-Based Workflow | It can be quickly reconfigured for diverse jobs. |

This decision requires matching the physics of the furnace to your specific material, process, and business objectives. As a provider of advanced, customizable high-temperature solutions—from Muffle and Tube to Rotary and complex CVD systems—KINTEK was founded on this principle. The optimal solution is rarely off-the-shelf; it is engineered.

Navigating these trade-offs requires a partner who understands both the metallurgy and the manufacturing system. To design a process that delivers flawless quality at scale, Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- Gravity as an Ally: The Counterintuitive Genius of Vertical Vacuum Furnaces

- Mastering the Void: How Custom Vacuum Furnaces Forge the Future of Materials

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- The Physics of Absence: How Vacuum Furnaces Defy the Limits of Heat

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites