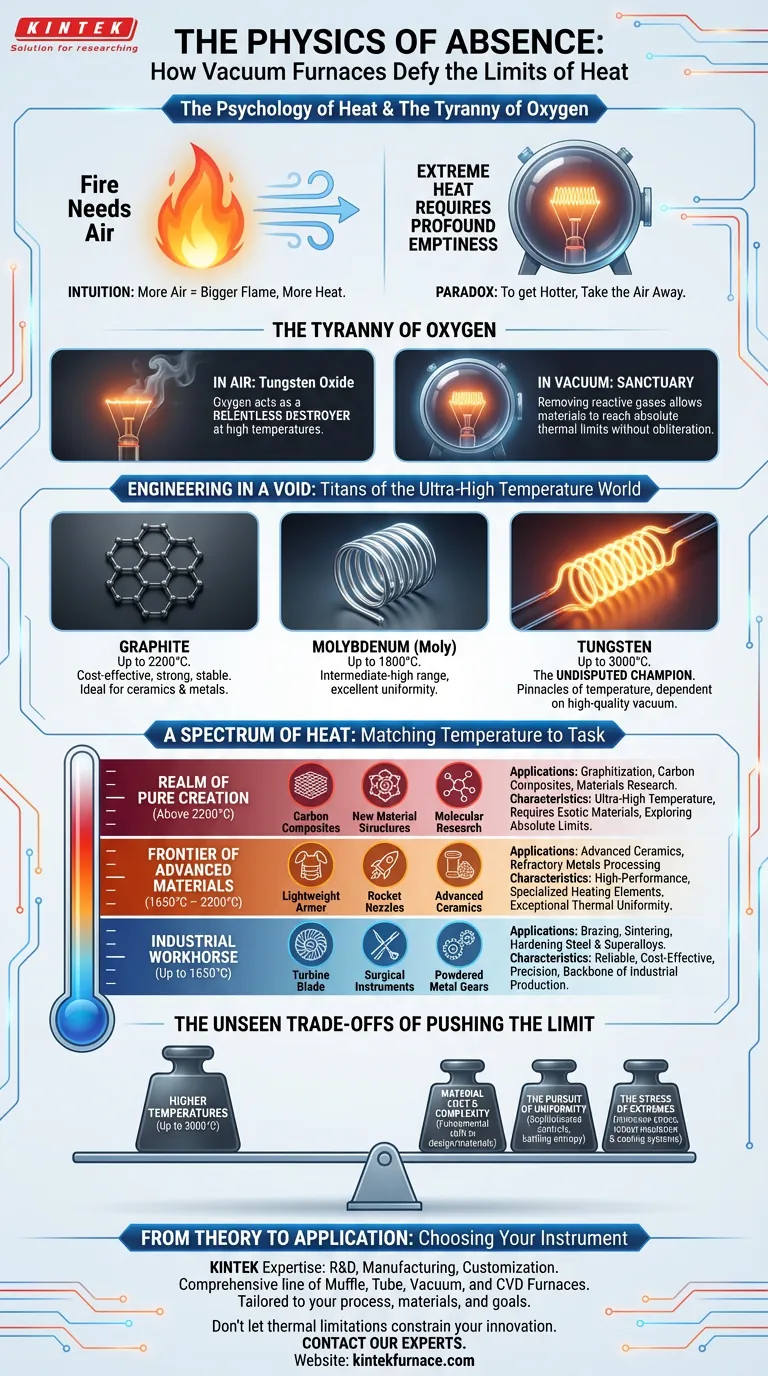

The Psychology of Heat

Our intuition about heat is tied to fire. From childhood, we learn that fire needs air to breathe. More air, bigger flame, more heat. It’s a simple, primal equation.

But to achieve the truly extreme temperatures required for modern materials science—temperatures that can forge next-generation alloys or grow flawless crystals—we must abandon this intuition.

To get hotter than the surface of many stars, you must first create a profound emptiness. You have to take the air away. This paradox is the heart of high-temperature vacuum furnace technology.

The Tyranny of Oxygen

Imagine an engineer trying to heat a filament of pure tungsten in the open air. For a fleeting moment, it would incandesce with a light so brilliant it rivals the sun. In the next moment, it would vanish in a wisp of yellow smoke—tungsten oxide.

At ambient temperatures, oxygen is a life-giving gas. At 2000°C, it becomes a relentless destroyer. It aggressively seeks to react with, corrode, and consume nearly any material it touches, including the very elements designed to generate the heat.

This is the fundamental physical barrier that standard furnaces can't cross. They are trapped by the chemistry of the atmosphere they operate in. A vacuum furnace solves this problem not by adding more power, but by changing the rules of the environment itself. By removing reactive gases, it creates a sanctuary where materials can be pushed to their absolute thermal limits without being chemically obliterated.

Engineering in a Void

Once the destructive influence of oxygen is removed, a new class of materials can be used to generate heat. These are the workhorses of the ultra-high temperature world, elements that would be useless in open air but become titans in a vacuum.

- Graphite: The cost-effective standard for temperatures up to 2200°C. In a vacuum, its strength and stability make it ideal for heating elements in furnaces processing ceramics and metals.

- Molybdenum: This refractory metal, often called "Moly," serves the intermediate-high range, pushing capabilities towards 1800°C and offering excellent uniformity.

- Tungsten: When the goal is to reach the pinnacle of temperature, up to 3000°C, tungsten is the undisputed champion. Its incredibly high melting point makes it perfect for the most demanding research and production applications, but it is utterly dependent on a high-quality vacuum for survival.

A Spectrum of Heat: Matching Temperature to Task

"High temperature" isn't a single destination. It is a spectrum of carefully controlled environments, each engineered for a specific purpose.

The Industrial Workhorse (Up to 1650°C)

This is where the aerospace, medical, and manufacturing industries thrive. Processes like brazing turbine blades, hardening surgical steel, and sintering powdered metals all occur in this range. These furnaces are defined by reliability and precision, forming the backbone of modern industrial production.

The Frontier of Advanced Materials (1650°C – 2200°C)

Entering this realm enables the creation of materials that didn't exist a generation ago. Here, advanced ceramics are fired to become lightweight armor, and refractory metals are processed for rocket nozzles. The applications demand not just heat, but exceptional thermal uniformity to create parts with flawless structural integrity.

The Realm of Pure Creation (Above 2200°C)

Operating from 2200°C to 3000°C is less about processing existing materials and more about creating new ones. This is the domain of graphitization, carbon composite development, and fundamental materials research. It is where scientists explore the absolute limits of matter, demanding furnaces that represent the pinnacle of engineering.

| Temperature Range | Typical Applications | Key Characteristics |

|---|---|---|

| 1000°C – 1650°C | Brazing, sintering, hardening of steel & superalloys | Industrial workhorse, cost-effective, reliable |

| 1650°C – 2200°C | Advanced ceramics, refractory metals processing | High-performance, specialized heating elements |

| Above 2200°C | Graphitization, carbon composites, materials research | Ultra-high temperature, requires exotic materials |

The Unseen Trade-offs of Pushing the Limit

Achieving higher temperatures is a battle against physics, and every degree comes with engineering trade-offs.

- Material Cost & Complexity: Moving from a graphite-based 2200°C system to a tungsten-based 3000°C system isn't a simple upgrade. It represents a fundamental shift in design, materials sourcing, and cost.

- The Pursuit of Uniformity: It is one thing to reach 2500°C at a single point; it is another entirely to hold an entire workspace at 2500°C with a variance of only ±5°C. This requires sophisticated multi-zone controls and advanced insulation, battling the forces of entropy.

- The Stress of Extremes: Extreme heat puts immense stress on every component. The insulation, the chamber walls, and the cooling systems of a 3000°C furnace must be far more robust than those of a 1300°C furnace, making them more complex to build and maintain.

From Theory to Application: Choosing Your Instrument

Selecting a vacuum furnace is about more than just picking the highest number on a spec sheet. It's about matching a precisely engineered tool to a specific scientific or industrial problem. Whether you are annealing standard alloys or exploring the frontiers of carbon science, the furnace is your primary instrument.

At KINTEK, our expertise in R&D and manufacturing is dedicated to building these precise instruments. With a comprehensive line of Muffle, Tube, Vacuum, and CVD furnaces, we provide the foundational technology for labs in aerospace, medicine, and advanced materials. Because every application is unique, our engineering capability is focused on customization—ensuring your furnace is perfectly tailored to your process, your materials, and your goals.

Don't let thermal limitations constrain your innovation. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

Related Articles

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection

- The Three-Axis Logic: How to Choose a Vacuum Furnace That Works

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection