The Allure of the Void: Why We Remove the Air

We have an innate bias for what we can see and touch. We think of a furnace as a tool for adding heat. But a vacuum furnace is equally defined by what it takes away: air.

This act of removal is not trivial. It is a deliberate strategy to gain absolute control over a material's environment, solving problems that heat alone cannot.

-

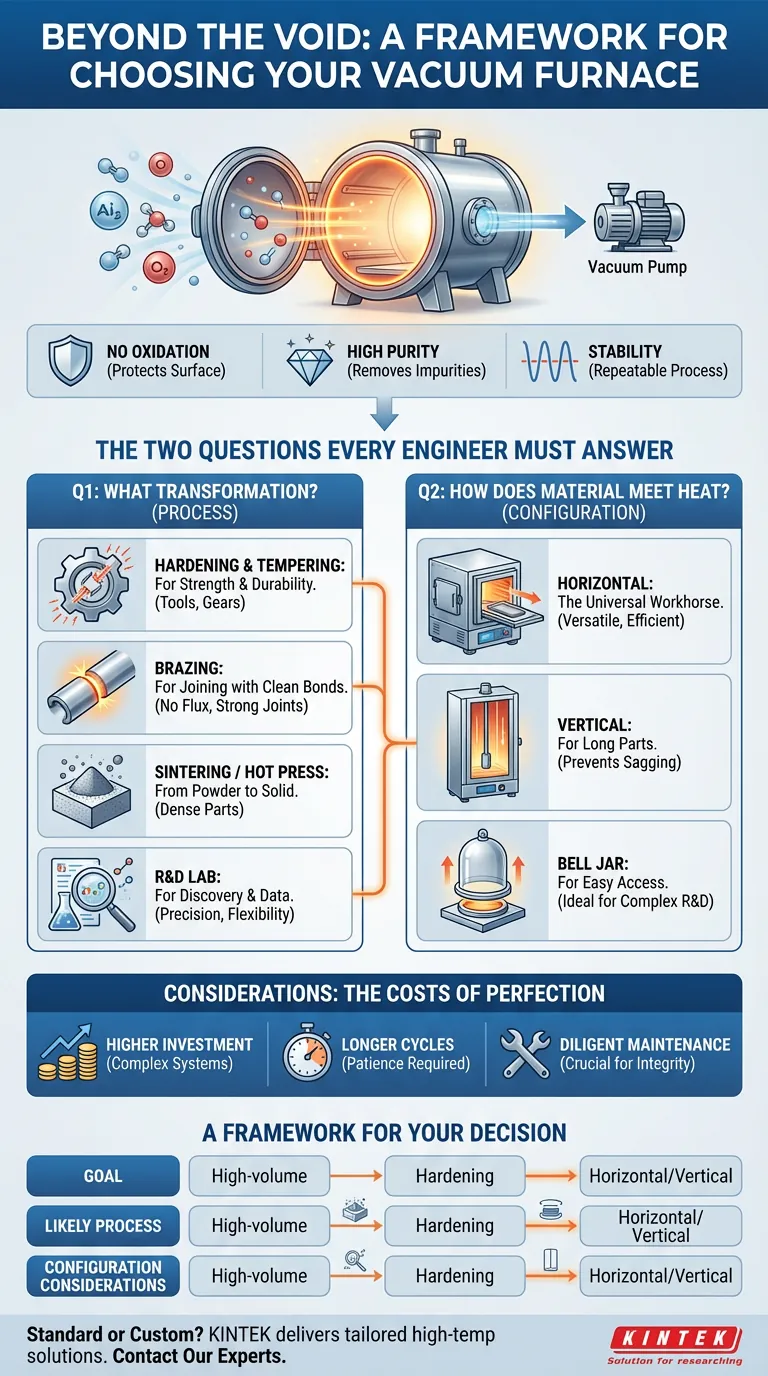

The Tyranny of Oxygen: In the presence of high heat, oxygen is an aggressive agent. It tarnishes, it weakens, it creates oxides that can ruin the surface of a critical aerospace component or a medical implant. The vacuum is a shield, creating a sanctuary where materials can be transformed without being corrupted.

-

The Hidden Impurities: Every material contains ghosts—trace elements and volatile compounds trapped within. As heat is applied, these impurities "outgas." In a normal furnace, they linger. In a vacuum, they are actively pulled away, resulting in a final product of exceptional purity and strength.

-

The Chaos of Fluctuation: A vacuum environment is inherently stable, allowing for incredibly precise and uniform temperature control. This transforms the process from a craft into a science, ensuring every cycle is identical to the last. For certified manufacturing, this repeatability isn't a feature; it's the foundation of trust.

The Two Questions Every Engineer Must Answer

Choosing a vacuum furnace is less like buying an appliance and more like formulating a scientific hypothesis. The equipment you choose is a direct reflection of the outcome you intend to create.

To find the right instrument, you must answer two fundamental questions.

Question 1: What Transformation Are You Creating?

This question is about your process—the specific change you are forcing upon the material.

Forging Strength

For this, you need a Hardening & Tempering Furnace. The goal is to manipulate the crystalline structure of metals like steel, creating a controlled internal stress that imparts hardness and durability. It’s the workhorse for creating tools, gears, and structural components that can withstand immense forces.

Creating Inseparable Bonds

Here, a Brazing Furnace is essential. The process involves joining two parts with a filler metal in an immaculate vacuum. With no oxygen, there is no need for corrosive flux. The resulting bond is clean, powerful, and often stronger than the parent materials themselves—a seamless integration of two into one.

Building from Dust

When you need to create a dense, solid object from a powder, you turn to a Sintering Furnace. It uses heat to fuse powdered metal or ceramic particles together. For materials that demand maximum density and strength, a Vacuum Hot Press Furnace adds the critical element of immense pressure to the process.

Exploring the Unknown

For R&D, the furnace is not a production tool but an instrument of discovery. Laboratory Furnaces, often specialized Tube Furnaces, are built for precision and adaptability. The goal isn't throughput; it's generating pure, reliable data. This is where flexibility is paramount, as the questions of tomorrow haven't been asked yet.

Question 2: How Does the Material Meet the Heat?

This question is about your configuration—the physical reality of how you handle the material. The answer is driven by physics, ergonomics, and workflow.

The Universal Workhorse: Horizontal Loading

This is the most common design. Parts are loaded horizontally through a front door. It is versatile, easily automated, and efficient for a wide range of components. It's the default choice for a reason.

Defying Gravity: Vertical Loading

Imagine a long, slender drive shaft heated to 1200°C. If laid flat, its own weight would cause it to sag, destroying its precise geometry. A Vertical/Bottom-Loading Furnace solves this. The part is oriented vertically, preserving its shape against the pull of gravity. The design is a direct answer to a specific physical constraint.

The Researcher's Dome: Bell Jar

A variation of the vertical furnace, the Bell Jar design offers unparalleled access. The chamber is lifted away, leaving the base exposed for easy loading and instrumentation. It’s ideal for complex R&D setups where frequent adjustments are the norm.

The Unspoken Costs of Perfection

A vacuum furnace offers near-perfect control, but this control comes at a price. It is a more complex machine, demanding a different mindset.

- Investment in Control: The pumps, seals, and advanced controls required for a high-vacuum environment mean higher initial costs and operational complexity.

- The Patience of a Vacuum: Pulling a deep vacuum takes time. Controlled cooling cycles also add to the overall process duration. It is a deliberate, not a rushed, process.

- The Discipline of Maintenance: The integrity of the vacuum is everything. A tiny leak can compromise an entire batch. This requires diligent, preventative maintenance of seals, pumps, and chamber surfaces.

A Framework for Your Decision

The right furnace is the one where the process and configuration align perfectly with your goal.

| Your Goal | Likely Process Furnace | Configuration Considerations |

|---|---|---|

| High-volume metal treatment | Hardening / Tempering | Horizontal for versatility, Vertical for long/symmetrical parts |

| Creating clean, strong joints | Brazing | Horizontal for most applications |

| Making dense parts from powders | Sintering / Hot Press | Depends on part size and production flow |

| Fundamental materials research | Laboratory / Tube | Bell Jar for access, Tube for specific atmospheres/gradients |

Standard models serve many industries well. But for those working at the edge of material science or tackling unique manufacturing challenges, an off-the-shelf solution may not be enough. This is where the ability to tailor a system to your exact needs becomes the most critical variable.

For challenges that require a furnace as unique as your research, our team is ready to help you build the perfect tool for the job. KINTEK's deep R&D expertise and manufacturing capability allow us to deliver fully customized high-temperature solutions, from vacuum and tube furnaces to advanced CVD systems.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

Related Articles

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation

- The Most Important Number in a Vacuum Furnace Isn't Its Temperature

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection

- The Architecture of Purity: Deconstructing the Vacuum Furnace System

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale