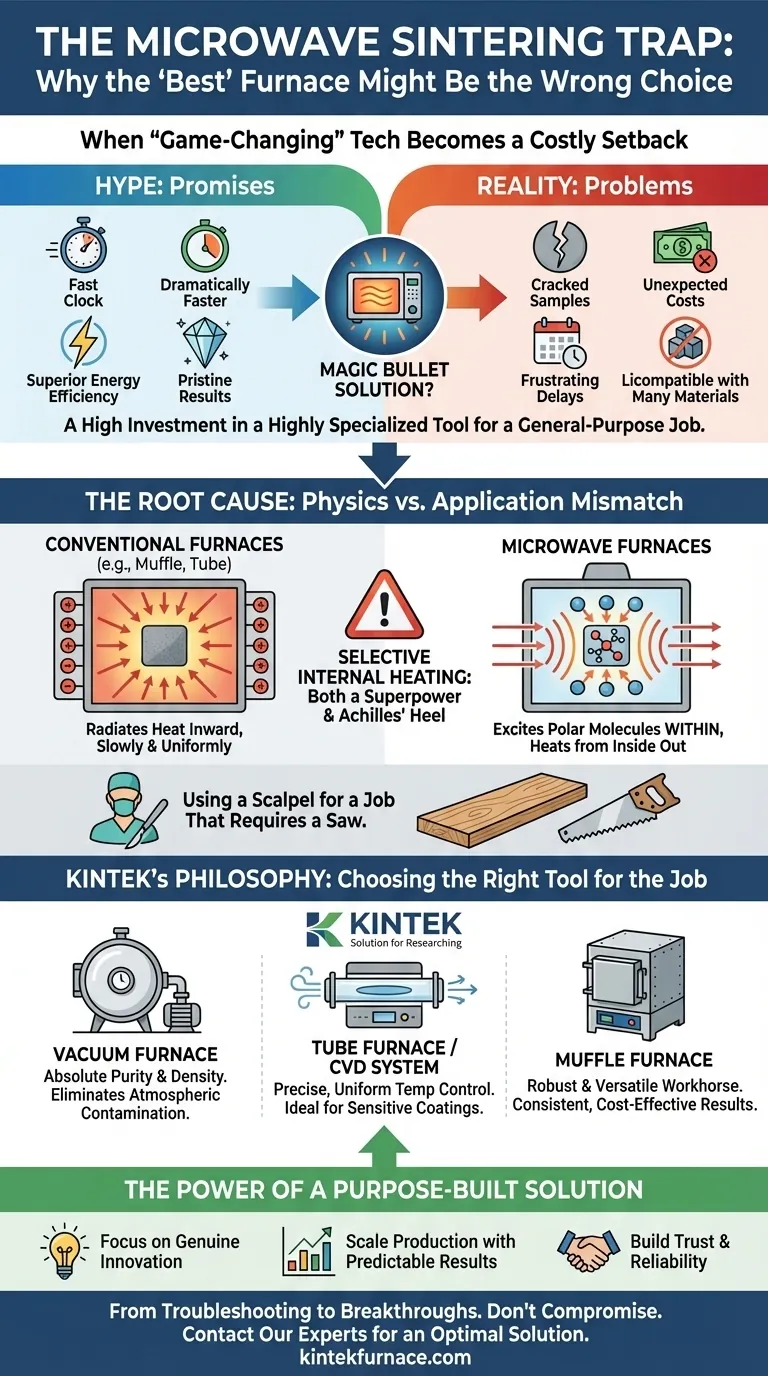

You’re under pressure. Your lab needs to develop higher-quality materials, faster. Deadlines are shrinking, and the demand for consistency has never been greater. You keep hearing about a seemingly perfect solution: microwave sintering. The promises are dazzling—dramatically faster processing times, superior energy efficiency, and pristine results. It feels like the one investment that could solve everything.

But what if this "magic bullet" solution creates more problems than it solves? What if the race for speed leads you down a path of cracked samples, unexpected costs, and frustrating delays?

When 'Game-Changing' Tech Becomes a Costly Setback

This scenario is more common than you think. A research institute invests hundreds of thousands of dollars in a state-of-the-art microwave sintering furnace, expecting to revolutionize their ceramic component production. Initially, the results on a specific zirconia powder are incredible.

Then, they try to process a different composite material. The sample cracks. They try a non-polar ceramic. It barely heats up. The team spends weeks trying to tweak parameters, only to realize the furnace is incompatible with half of their project portfolio.

The promised speed is lost to a steep learning curve and extensive troubleshooting. The high initial investment is now compounded by wasted materials, project delays, and the dawning realization that they bought a highly specialized tool for a general-purpose job. The business consequences are severe: R&D timelines are pushed back, production forecasts are missed, and confidence in the lab's capabilities begins to erode.

The Real Culprit: A Mismatch Between Physics and Application

Many labs fall into this trap because they focus on the technology's promised benefits without first diagnosing the root of their problem. The issue isn't that microwave sintering is a bad technology—it's that its fundamental operating principle makes it brilliant for some applications and completely wrong for others.

Here's the simple truth:

- Conventional Furnaces (like Muffle or Tube furnaces) work like a convection oven. They heat the chamber, and that heat radiates inward, slowly and uniformly warming the material from the outside in.

- Microwave Furnaces work like, well, a microwave. They don't heat the chamber; they use microwave energy to directly excite specific polar molecules within the material itself, causing it to heat from the inside out.

This "selective internal heating" is both microwave sintering's superpower and its Achilles' heel. It’s why the common "solutions"—like endlessly adjusting power and temperature ramps—often fail. If the material itself doesn't have the right molecular properties to couple with microwaves, no amount of tweaking will make it work effectively. You’re trying to use a scalpel for a job that requires a saw. The problem isn't a faulty tool; it's the wrong tool for the job.

Beyond the Hype: Choosing the Right Tool for the Job

To truly achieve speed, efficiency, and quality, you need to stop asking, "What is the newest furnace?" and start asking, "What is the optimal heating mechanism for my specific material, geometry, and desired outcome?"

Answering this question requires a deep understanding of the tradeoffs between radiative heating, vacuum environments, and atmospheric controls. This is where a partnership with experts who master the entire spectrum of furnace technologies becomes your greatest strategic advantage.

At KINTEK, our philosophy is built on this principle. We don't push a single technology. Instead, we leverage our deep R&D and in-house manufacturing capabilities to provide the furnace that perfectly matches your application.

- Need absolute purity and density for mission-critical components? A Vacuum Furnace is likely the superior choice, eliminating atmospheric contamination that no microwave furnace can.

- Need precise, uniform temperature control for sensitive coatings? The controlled environment of a Tube Furnace or a CVD System provides reliability that selective heating cannot guarantee.

- Need a robust, versatile workhorse for a wide range of materials? A well-designed Muffle Furnace often delivers the most consistent, cost-effective results without the operational complexity.

Our goal is to deliver a solution engineered for your success, whether it's one of our advanced standard models or a fully customized system built to your exact specifications.

From Troubleshooting to Breakthroughs: The Power of a Purpose-Built Solution

Imagine a future where you are no longer fighting with your equipment. When your furnace is perfectly aligned with your process, you stop wasting time and resources on re-running failed experiments. Instead, you can focus on genuine innovation.

You can confidently explore new material compositions that were previously "too difficult" to process. You can scale production with predictable, repeatable results, building trust with your stakeholders and customers. Your lab transforms from a place of constant troubleshooting into a hub of reliable, high-impact R&D. This is the new potential that opens up when you're equipped with not just a product, but a correct, purpose-built solution.

Your material challenges are unique. Don't settle for an off-the-shelf solution that forces you to compromise. Our team of engineers and material scientists are ready to go beyond the spec sheet to understand your process, your goals, and your frustrations. Let's work together to design a furnace solution that doesn't just work, but gives you a decisive advantage. To discuss your specific project and discover the optimal heating technology for your needs, Contact Our Experts.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Muffle Oven Furnace for Laboratory

Related Articles

- Beyond Heat: The Physics of Control in a Tube Furnace

- The Controlled Universe: Why Tube Furnaces Prioritize Precision Over Scale

- Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

- Mastering the Micro-Environment: The Art and Science of the Laboratory Tube Furnace

- The Art of Isolation: Mastering Material Properties with Tube Furnaces