Dental Furnace

Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

Item Number : KT-DS10

Price varies based on specs and customizations

- Heating speed

- 200℃/min max. (392°F /minute)

- Max temperature

- 1530℃

- Firing chamber diameter

- 9cm(3.5")

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD/MPCVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

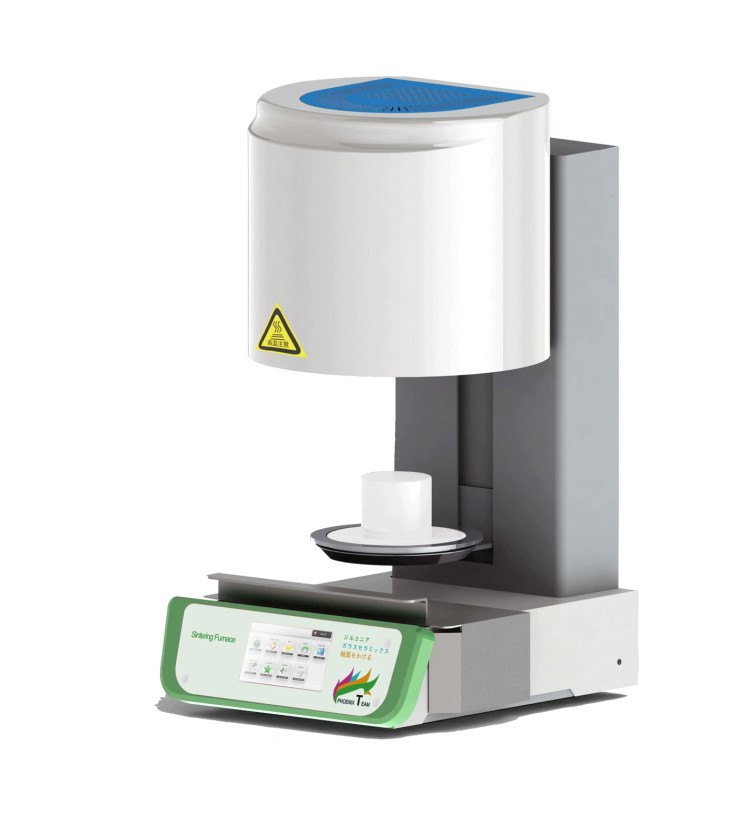

Product Visuals: The PHOENIX-9C In Detail

PHOENIX-9C Speedy Sintering Furnace: Unmatched Performance for Your Lab

The PHOENIX-9C is engineered to deliver exceptional speed, precision, and ease of use, making it an indispensable asset for modern dental laboratories and chairside applications.

Speed & Efficiency Redefined

- Rapid Sintering & Glazing: Accelerate your workflow with rapid sintering of fully anatomized zirconia and complete quick glazing in as little as 9 minutes.

- Fast Heating & Cooling Cycles: Maximize your productivity with a swift heating rate of up to 200°C per minute and advanced automatic rapid cooling technology.

- Immediate Operation: Save valuable time and start your processes instantly – no preheating is required.

Uncompromising Precision & Quality

- Superior Temperature Accuracy: Depend on high-quality automatic temperature regulation, maintaining an actual temperature error within an impressive +/- 1.5°C for consistent, reliable results.

- Consistent Outcomes: Our hyperbolic sintering system, featuring automatic temperature calibration before each baking procedure, ensures predictable and repeatable performance.

- Contamination-Free Processing: High-purity silicon carbide (SiC) heaters prevent metal pollution, safeguarding the integrity and aesthetics of your restorations.

User-Friendly Design & Operation

- Compact & Ergonomic: Recognized as a leading small chairside sintering furnace globally, its compact footprint is ideal for any lab space, enhancing workflow convenience.

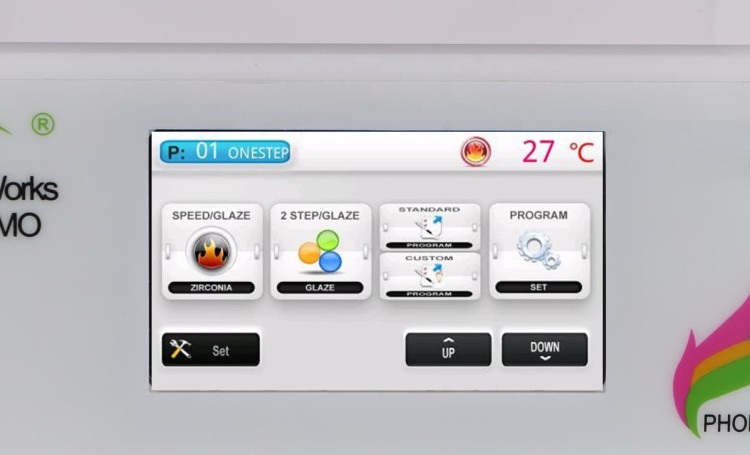

- Intuitive Control: Navigate settings and programs effortlessly using the clear, real-color touch screen interface.

- Smooth & Quiet Performance: Enjoy a stable, jitter-free operation thanks to the precision stepping motor drive, complemented by a noiseless, programmable-speed pallet for a better working environment.

Versatility & Enhanced Control

- High-Temperature Capability: Address a wide range of applications with a maximum settable temperature of 1530°C.

- Extensive Program Customization: Tailor operations precisely to your needs with 90 customizable programs, alongside convenient built-in options and adjustable pre-drying times.

- Optimized Capacity: Efficiently sinter up to 4-10 restorations (on a 60mm pallet) in a single cycle.

- Reliable Monitoring & Safety: Stay informed and operate with confidence, thanks to clear status indications and audible error alarms.

Ready to Enhance Your Laboratory's Capabilities?

Discover how the PHOENIX-9C Speedy Sintering Furnace can revolutionize your workflow and deliver outstanding results. For more information, to discuss custom configurations, or to get a personalized quote, please contact our specialists today. We're here to help you find the perfect high-temperature solution for your needs.

Technical Specifications

| Heating speed | 200℃/min max. (392°F /minute) |

| Max temperature | 1530℃ |

| Max temperature holding time | 2 hours |

| Electric power supply | 100-120V 50/60HZ 230V 50/60HZ |

| Rated current | 14.5ampere@110V 7.0ampere@230V |

| Rated output power | max 1500w |

| Dimension | H27cm x W36cm x D56cm |

| Firing chamber diameter | 9cm(3.5") |

| Net weight | 20Kg |

| Weight with package | 25.5Kg |

Optimal Operating Environment

- Indoor use

- Ambient temperature: 2°C to 40°C

- Relative humidity 80% at 31°C

- Maximum altitude: 1500 m (Special Model:3500m)

- Rated voltage fluctuations must not exceed plus/minus 10% of the rated voltage

Standard Package Contents

- 1 Furnace

- 1 firing pan

- 1 connection cable for the mains power supply

- 1 instructions

- 1 Burning rack

Trusted by Industry Leaders

FAQ

What Is The Principle Of A Porcelain Furnace?

What Is A Dental Furnace Used For?

What Are The Advantages Of Using A Porcelain Furnace?

What Are The Key Features Of A Dental Furnace?

What Are The Applications Of A Porcelain Furnace?

How Does A Dental Furnace Work?

What Safety Features Should A Porcelain Furnace Have?

What Are The Advantages Of Using A Dental Furnace?

What Advanced Features Do Some Porcelain Furnaces Offer?

What Safety Features Should A Dental Furnace Have?

What Types Of Dental Furnaces Are Available?

4.9 / 5

Incredibly fast delivery! The furnace works like a charm, perfect for our dental lab. Highly recommend!

4.8 / 5

Top-notch quality and durability. This furnace has transformed our ceramic restorations. Worth every penny!

4.7 / 5

The technological advancement in this furnace is impressive. Easy to use and delivers consistent results.

4.9 / 5

Superb value for money! The furnace is reliable and has significantly improved our workflow efficiency.

4.8 / 5

Love the precision and speed of this furnace. It’s a game-changer for our dental practice.

4.7 / 5

The furnace arrived earlier than expected. Performance is outstanding, very satisfied with the purchase.

4.9 / 5

Durable and high-quality build. This furnace has exceeded our expectations in every way.

4.8 / 5

The transformer included is a great addition. This furnace is a must-have for any dental lab!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

Precision Vacuum Press Furnace for labs: ±1°C accuracy, 1200°C max, customizable solutions. Boost research efficiency today!

Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

KinTek Vacuum Porcelain Furnace: Precision dental lab equipment for high-quality ceramic restorations. Advanced firing control & user-friendly operation.

Vacuum Induction Melting Furnace

Explore KINTEK's Vacuum Induction Melting Furnace for high-purity metal processing up to 2000℃. Customizable solutions for aerospace, alloys, and more. Contact us today!

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

KINTEK's Vacuum Pressure Sintering Furnace offers 2100℃ precision for ceramics, metals, and composites. Customizable, high-performance, and contamination-free. Get a quote now!

Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

KINTEK's Vacuum Molybdenum Wire Sintering Furnace excels in high-temperature, high-vacuum processes for sintering, annealing, and material research. Achieve precise 1700°C heating with uniform results. Custom solutions available.

Vacuum Heat Treat Sintering and Brazing Furnace

KINTEK Vacuum Brazing Furnaces deliver precision, clean joints with superior temperature control. Customizable for diverse metals, ideal for aerospace, medical, and thermal applications. Get a quote!

600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

600T Vacuum Induction Hot Press Furnace for precise sintering. Advanced 600T pressure, 2200°C heating, vacuum/atmosphere control. Ideal for research & production.

Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

Compact vacuum tungsten wire sintering furnace for labs. Precise, mobile design with superior vacuum integrity. Ideal for advanced material research. Contact us!

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

KINTEK Mesh Belt Furnace: High-performance controlled atmosphere furnace for sintering, hardening & heat treatment. Customizable, energy-efficient, precise temperature control. Get a quote now!

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.

Related Articles

Cracked Zirconia, Inconsistent Shades: The Real Reason Your Sintering Furnace Is Failing You

Stop blaming materials. Discover the root cause of inconsistent dental sintering—the 'one-size-fits-all' furnace—and how a purpose-built solution ends costly remakes.

Beyond Maintenance: The Real Reason Your Dental Furnace Delivers Inconsistent Results

Tired of inconsistent zirconia shades and costly remakes? Discover why maintenance isn't the whole story and how a furnace's core design is the key to perfect results.

The Physics of a Flawless Smile: Mastering Material Science with Vacuum Furnaces

Vacuum furnaces create a pure environment, eliminating porosity and contamination in dental ceramics for unmatched strength, aesthetics, and repeatability.

Mastering the Void: How Vacuum Furnaces Forge Strength and Beauty in Dental Restorations

A vacuum furnace actively removes atmospheric gases during firing, eliminating porosity and oxidation for stronger, more aesthetic dental restorations.

Beyond the Limits of Quartz: A Scientist's Guide to Corundum Tube Furnaces

Learn why corundum's stability and purity justify its cost for high-temp lab work, and when to choose it over quartz for reliable results.

Beyond 1600°C: The Psychology of Precision in Alumina Tube Furnaces

An alumina tube furnace isn't just a heater; it's a controlled universe. Mastering it requires understanding the trade-offs between heat, stability, and control.

The Microwave Sintering Trap: Why the 'Best' Furnace Might Be the Wrong Choice for Your Lab

Is microwave sintering always the best choice? Discover the hidden costs and learn a smarter way to select the right high-temperature furnace for your lab.

How Vacuum Hot Press Furnaces Transform Advanced Material Engineering

Vacuum hot press furnaces enable precise material synthesis for aerospace, electronics, and energy sectors, enhancing density, strength, and reliability.

Why Your Sintered Parts Fail: It’s Not Just About Heat, But Pressure and Purity

Struggling with porous, weak, or contaminated sintered materials? Discover why simply raising the temperature isn't the answer and how the interplay of heat, pressure, and vacuum is the key.

The Hidden Saboteur in Your High-Temperature Furnace: Why Your Melts Are Inconsistent—And How to Fix It

Struggling with contaminated or inconsistent metal melts? Discover the hidden cause in traditional heating and how a different approach ensures purity and control.

Beyond the Parts List: The Real Reason Your Vacuum Hot Press Fails (And How to Fix It)

Frustrated with inconsistent vacuum hot press results? Discover why just upgrading parts fails and how a system-based approach unlocks repeatable success.

Why Your High-Temperature Furnace Fails (Even When the Temperature Is Right)

Discover why your high-temp experiments fail despite correct settings. Learn how the heating element material—not just temperature—is the key to success.